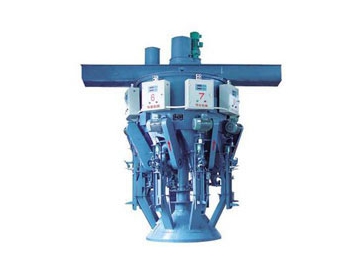

Automatic Bagging Scale, SYC-DCS-600S Weigh Bagging Machine

The SYC-DCS-600S automatic bagging scale automatically carries out all packaging processes, from bag supply to the final packaging process. It is primarily used for powder and particulate mixed weighing packaging, for things such as animal feed. The weigh bagging machine consists of the feeding system, weighing system and weighing instrument.

Weighing range: 40-50kg

Weighing error: ±0.1%F.S ~ ±0.2%F.S

Minimum weighing speed: 500 (bags/h)

Air pressure: 0.5-0.7 Mpa

Total air consumption: 8m³/h

Total power consumption: 8Kw

Ambient temperature: 0-40℃

Ambient humidity: no more than 90%RH at 40 degrees centigrade, allowing greater humidity at low temperatures.

Dimension (length * width * height): 6172*3742*3321mm

1. High weighing speed and accuracy

It uses advanced weighing instruments PLC dual-core control technology, and use belt scales for weighing calculations due to weighing powder. The A/D conversion speed is 200 times/second, which ensures both the weighing speed and accuracy of the equipment. The feeding quantity is servo controlled, ensuring a higher weighing accuracy.

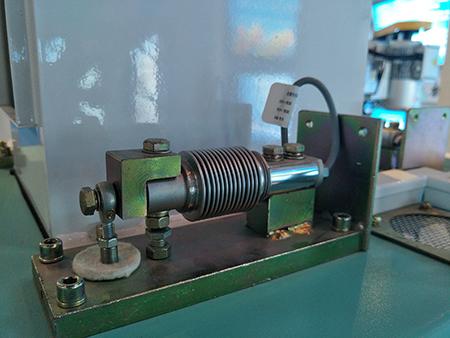

2. Rational layout and efficiency improvement

The three sensor layouts form a triangular shape, and the weighing cylinder is suspended in the 3 sensors, ensuring the weigh bagging machine is balanced and stable, thus improving the service life and ensuring it is not disturbed by workshop machine vibration. The sensors also ensure the equipment has a higher stability and interference resistance. The sensors use METTER and TOLEDO in order to ensure the system is stable and reliable.

3. Easy operation

Operating this equipment is quick and easy through the use of a touch screen, which improves the level of intelligent workshop operations. This also allows the weigh bagging machine to simultaneously carry out different material packaging weights. This equipment also features long term production report storage, as well as a data communication function.

4. Safe and hygienic

In order to ensure the food safety, we use stainless steel for all parts that come into contact with the feed, no matter what stage in the process the feed is in. The internal grinding process is smooth, with no dead corners and no residue, thus preventing mildew growth.

5. Sealing structure to eliminate rodent damage and acidification corrosion.

The SYC-DCS-600S automatic bagging scale uses a closed working chamber and all circuits, sensors, solenoid valves are made using a s steel wire groove or protective iron box. The corrosion and steam wear are also completely isolated from the cylinder and sensors, thus extending the equipment service life.

Touchscreen

Touchscreen  Cylinder

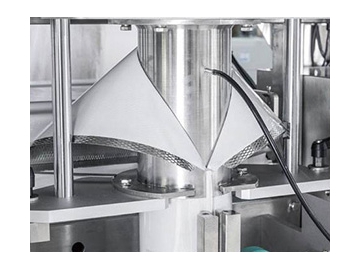

Cylinder  Sewing Bag Device

Sewing Bag Device