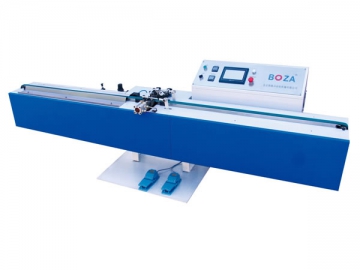

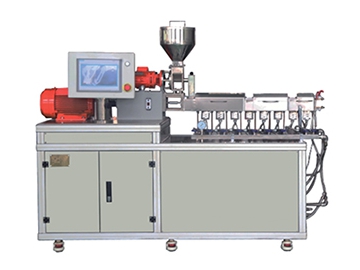

Manual Two Component Sealants Extruder (Extrusion Pumps for Insulating Glass Manufacturing)

To assists customers with the sealing process of IG production, we developed the manual two component sealants extruder, which is applicable for most two-component sealants, such as polysulphide sealants, silicone sealant, and polyurethane sealant. Designed with a pneumatic control system, the two component sealant dispenser is equipped with the main parts supplied by well-known manufacturers. It has a stable and reliable performance, and is considered an ideal sealing device for the final sealing process in IG production and glass curtain wall production.

Technical Data of Manual Two Components Extruder

Model: MSE-A

Standard drum: 200L(for basic component) 20L (for catalyst)

Mixing ratio: 6:1 - 14:1

Air pressure: 0.8Mpa;

Sealant: polysulfide/silicon/polyurethane;

Machine size:1500mm(L) ×1200mm(W) ×1900mm(H).

Features

1. The sealant coating machine has an appealing shape, laconically structured and is easy to maintain.

2. It has a high sealing efficiency, high continuity and even mixing.

3. The mixed sealants have a stable performance.

4. The sealant mixing system uses an advanced static mixer. The stainless steel mixing core has a smooth surface, reducing the resistance and ensuring a larger sealant supply under the same pressure