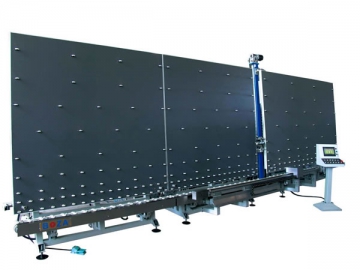

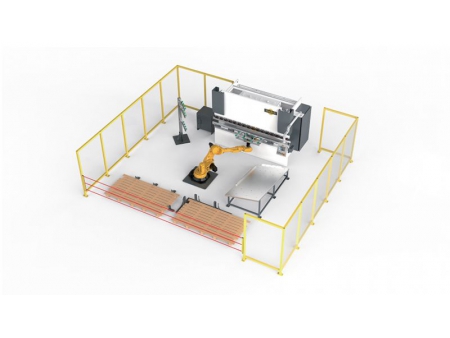

Automatic Sealing Robot

We have developed a full line of insulating glass (IG) equipment, including the automatic sealing robot. It consists of two main parts-the sealant extruder and the PLC device, which allow the sealing robot to be designed with a feeding device, sealant coating device, discharging device, gluing device, sealant supply device, super charger, hydraulic system, and electric system.

Technical Data

Minimum Dimension of Glass: 600mm(L) x400 mm(H);

Maximum Dimension of Glass: 4000mm(L)X2000mm(H);

IG thickness: 16-50mm;

Height(for working):500mm;

Gluing Speed: 5-35m/min;

Adhesive Thickness: smaller than18mm;

Glue Supply Pressure: smaller than350kg/cm²;

Angle: 6~ 9°;

Power: 15kW;

Max. Glass Weight: 350kg

Air Pressure: 0.6-0.7MPa.

Features

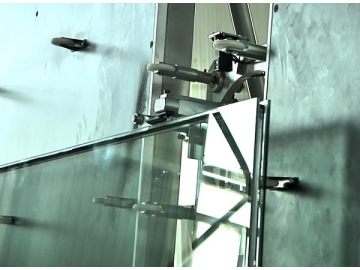

1. Special Relocation Mechanism

The gluing part of the sealant spreading machine uses a special relocation mechanism, ensuring the gluing nozzle will touch the insulating glass, but not break it. It can also adapt to a certain range of displacement errors within the IG unit.

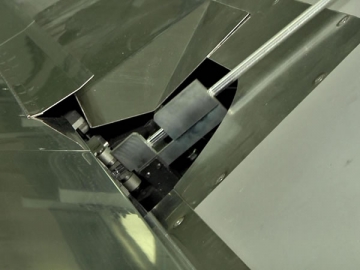

2. Easy Parameter Adjustment

The sealing width is adjustable, simply by putting in the parameters, a convenient and accurate process. The sealing depth can also be automatically detected. The sealing speed is controlled by the sealing depth and the sealant quantity, ensuring the quality. Adding sealant to the glass edges ensures the sealing quality on the glass turning.

3. Quality Electric Elements

All important electrical parts on the dispensing equipment use imported famous brand products, including the servo motor, controller, low-voltage apparatus, sensors, fiber optic photo switches and more. These prolong the service life and ensure the automatic sealing robot is reliable.

4. Imported Key Parts

All important parts are imported, including the servo precision reducer, guide rail and slider. This ensures the equipment is stable, safe and reliable, while making sure the automatic sealing robot satisfies specific accuracy requirements.

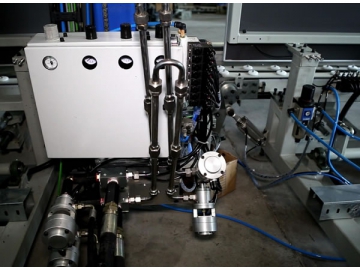

5. Double Glue Supply System

There are two hydraulic glue supply systems. Users can freely switch between the two, without needing to stop the machine. The hydraulic system uses a hydraulically-powered station that controls the oil pump, which in turn controls the sealant quantity. The black glue will supply a specified quantity through the mechanical linkage.

6. Touch Screen and HMI

This IG sealant equipment uses a touch screen man to machine interface, graphic combinations, and easily understandable information and operations.

7. Automatic Control

An automatic digital control system ensures the automatic sealing robot’s precision and sealant supply precision through the servo motor. The system also has a unilateral sealing, alarming, automatic determination and lock functions.

8. Usage

This automatic sealing robot can work individually or it can be matched with an IG unit production line. The latter leads to a higher working efficiency.

| Item | Model & Specification | Trademark | Place of Origin |

| Air switch | Schneider | China | |

| DC power supply | Meanwell | Taiwan, China | |

| Relays | Schneider | Taiwan, China | |

| Touch screen | 10inch | Schneider | Taiwan, China |

| Servo motor & drive | 1.5kW(with band brake) | Fuji | Japan |

| Servo motor & drive | 1.5kw *3 | Fuji | Japan |

| Servo motor & drive | 0.75 kW | Fuji | Japan |

| Servo motor & drive | 0.4 kW*5 | Fuji | Japan |

| CPU module | TRIO | UK | |

| Extension module | TRIO | UK | |

| Hydraulic proportional amplifier | HUADE | China | |

| Rotary encoder | E40H 6-2500 | AUTONICS | Taiwan, China |

| Pneumatic duplex pieces | SMC | Japan | |

| Solenoid valve | AIRTAC | Taiwan, China | |

| Cylinder | SMC | Japan | |

| Linear slide | HIWIN | Taiwan, China | |

| Planetary reducer | Eisele | Germany | |

| Timing pulleys | Megadyne | Italy | |

| Timing belts | Megadyne | Italy | |

| Hydraulic station | Dakin | China |

Details of automatic sealing robot