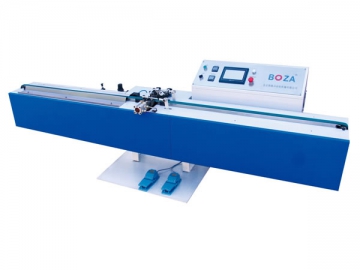

Automatic Desiccant Filling Machine

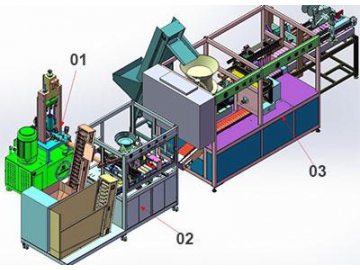

As a professional IG machinery supplier, we have exerted great efforts in the R&D and manufacture of automatic desiccant filling machine which is designed to fill aluminum spacers or warm edge spacer with desiccant.

Models Available

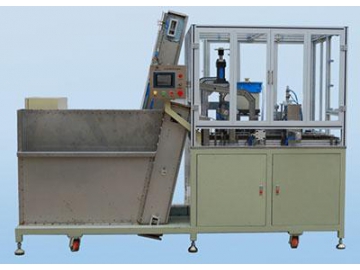

Automatic desiccant loader with drilling holes on the back of the spacer.

Technical Data of Automatic Desiccant Filler

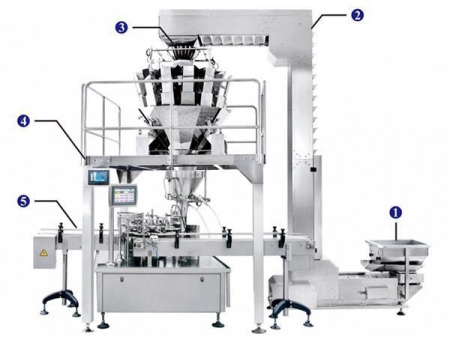

Model: DF-H;

Air pressure: 0.6MPa;

Power supply: AC220V,50Hz;

Power: 1kW;

Dimension: 835mmW×1450mmD×3660mmH;

Desiccant diameter scope: 0.5-0.8mm;

Filling speed: 4-8s(1000×1000mm9A)

Spacer width: 9-24mm.

Features of Automatic Desiccant Filling Machine

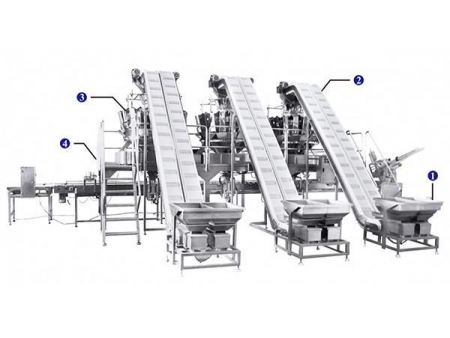

1. Applicable to spacers shaped by the automatic spacer bending machine and ordinary straight pin spacers;

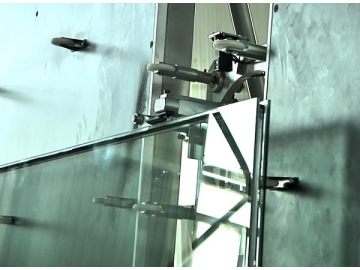

2. Adjustable filling height(according to the frame size);

3. Desiccant storage tank for automatic feeding;

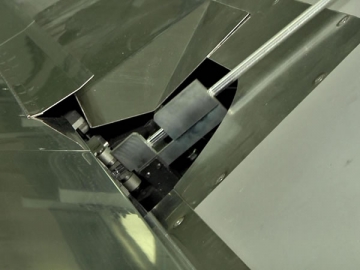

4. Equipped with bits which avoid damage or bur of holes and automatically close the filling holes to ensure no leakage after the filling finished;

5. Filling time set digitally.

Working Principle

As a common used automatic molecular sieve filling machine for insulating glass industry, this desiccant filling machine can automatically drill holes on the spacers. The insertion of desiccants is done by pressure and the control system assures the perfect filling. The loading holes with butyl will be closed automatically. To fill big size spacers, the working head can be raised pneumatically till it reaches the desired position.