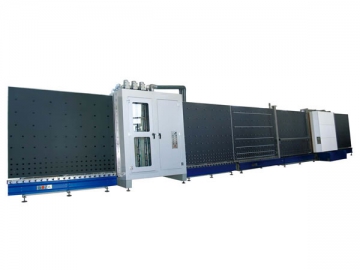

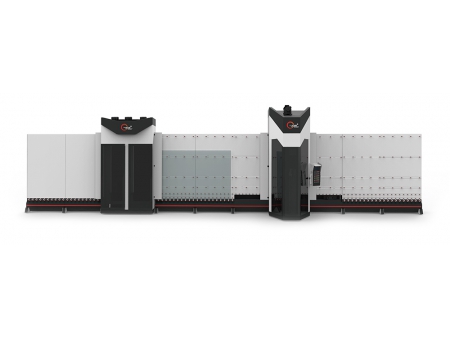

Automatic Vertical Edge Deleting Machine

As a reliable automatic glass machinery provider, Boza provides customers with automatic edge deletion machines to remove the low-e coating layer on glass (a chemical treatment of the glass surface to improve both the thermal and luminosity characteristics) from panel edges. With an easy operation and reliable performance, the edge grinding machine has been widely used in glass processing and manufacturing industries.

Technical Data

Model: EDV-H

Processing size

Max.2400mm×3600mm, Min.400mm×600mm

Glass processing thickness: 5-20mm

Processing speed: adjustable speed, Max. Processing speed 20m/min

Striping width: 8-200mm

Grinding wheel rotate speed: 0~3000r/min, adjustable.

Features of the Automatic Edge Deletion Machine

1. The stripping width error is smaller than 1mm, and the stripping is completed uniformly, with no ripples, waves, or filaments. The stripping efficiency is ˃85% (for reference).

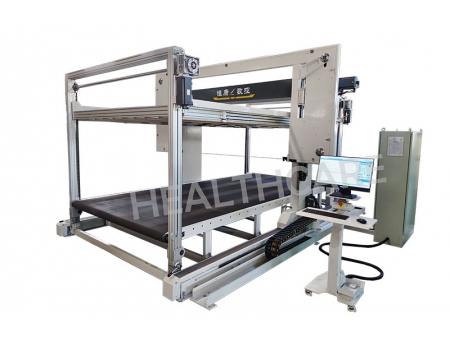

2. The automatic machine is equipped with a full servo conveying system and a TRIO control system.

3. It is capable of removing a curtain wall (step glass) film and scalene film with one operation. The deleting width for overlapped area is also adjustable.

4. Manual operations are available for each function, useful in debugging and future maintenance.

5. It is equipped with a dust suction device to mitigate dust pollution.

6. The input and output parts can be run asynchronously, improving productivity.

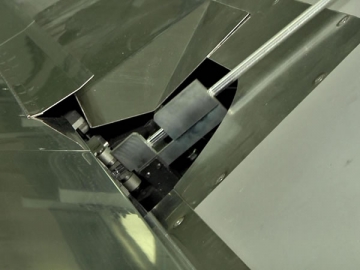

7. A grinding wheel is open for mechanical dressing to ensure clearer grinding.

8. The stripping speed is adjustable (according to different film types and expected stripping effect).

9. Six servo motor control systems and an adjustable linear dimension are supplied to guarantee a higher accuracy.

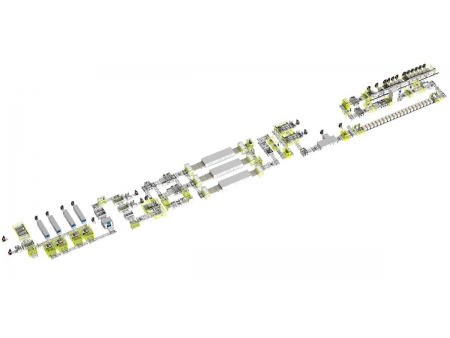

10. This machine can obtain an automatic connection to an insulated glass production line, saving time and labor costs.

11. The grinding wheel's feeding is automatically controlled by the motor to avoid wear on the grinding wheel and rollers.

12. The vertical low-e edge deletion machine can handle specially shaped glass panels, including the glass panels with holes for point-supported glass curtain wall system.

Working Principle

1. The low-e edge deletion table uses a single head that can rotate continuously to grind all 4 sides of a panel and edges of glass panels of any shape.

2. The abrasive head, which generates almost no dust during operation, runs vertically on linear guide rail. All movements are controlled by the PLC.

3. The outlet conveyor of the IG machinery is equipped with a motor-driven horizontal synchronous belt which is coated with polyurethane for high wear resistance.

4. The low-e edge deletion machine can also be used individually, or matched with an I.G. Line.

| Items | Types | Brand | Made in |

| Touch Screen | 10 inch | weinview | Taiwan ,China |

| Synchronous Belt | 50-AT10 | Megadyne | Italy |

| Synchronizing Wheel | 50-AT10-25 | Megadyne | Italy |

| Servo Motor | 1KM | Schneider or Fuji | France or Japan |

| Grinding Motor | 0.75KM | Schneider or Fuji | France or Japan |

| Reducer | EISELE | Germany | |

| Extended Module | TRIO | UK | |

| Motion Controller | MC405 | TRIO | UK |

| Laser Sensor | KEYENCE | Japan | |

| Linear Slide | HIWIN | Taiwan ,China | |

| Cylinder | Airtac | Taiwan ,China | |

| Solenoid valve | Airtac | Taiwan ,China | |

| FRL | SMC | Japan | |

| Air-vent Valve | SMC | Japan | |

| Air-Switch | 3P-16A | Schneider | China |

| Power | Meanwell | Taiwan , China | |

| Electric Relay | Schneider | France |

Details of automatic edge deletion machine