Chloride and Potassium Removal System (CPR)

Request a Quote

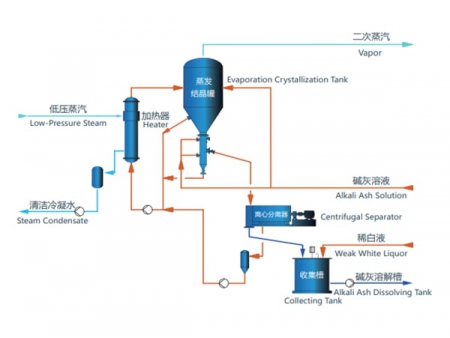

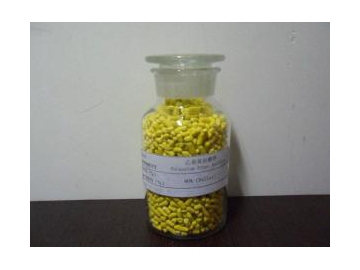

In the kraft chemical recovery process, the accumulation of non-process elements in the system will cause corrosion damage to the equipment, which affects the normal operation of equipment. These non-process elements are mainly chlorine and potassium. The content of chlorine and potassium in the pulping system can be reduced by removing chlorine and potassium from the alkali ash in the alkali recovery boiler. The chlorine and potassium removal system is used to evaporate and crystallize alkali ash solution for separating the useful salt from non-process elements, which achieves the purpose of chlorine and potassium removal.

Benefits

- Removes non-process elements in alkali ash

- Improves the service life of the pulping and papermaking equipment

- Reduces frequency of shutdown and steam purging of the recovery boiler

- Decreases the steam consumption during steam purging in the recovery boiler

- Achieves inorganic salt separation by crystallization

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos