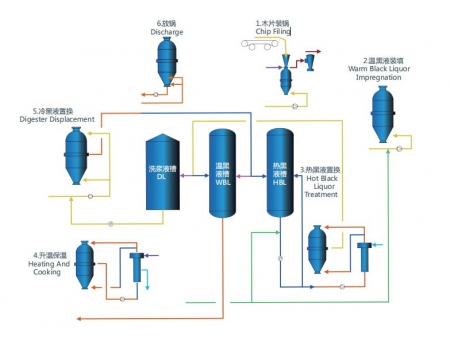

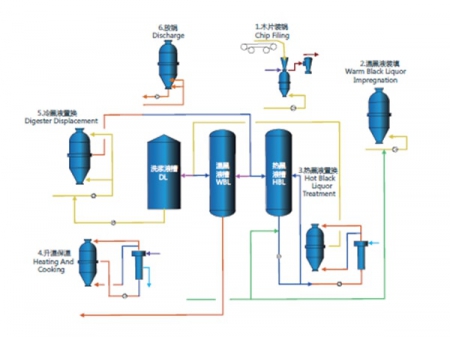

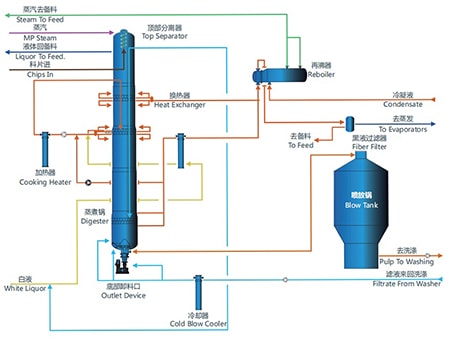

Vertical Continuous Displacement Cooking System (VCDC)

Request a Quote

Featuring energy-saving and emission reduction, vertical continuous displacement cooking is an extended delignification process used in chemical pulp mills. This cooking system is an upgraded alternative to straw pulp horizontal tube continuous cooking system. The vertical continuous displacement cooking system in the international market only can be applicable to the wood materials, but FJLIME’s option is suitable for a variety of materials. Our vertical continuous displacement cooking fills the technological gap in the domestic pulp and paper industry.

Features

- Low steam consumption (0.8-1.3 tons of steam / pulp for vertical continuous cooking; 2.2 tons of steam / pulp for horizontal continuous cooking)

- Low kappa numbers, good strength, increased yield

- Decreases the chemicals consumption when bleaching, reduce waste water pollution

- Comes with significant energy saving and emission reduction.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos