Water-cooled Vibration Test System

Introduction

1. The water-cooled vibration test system is characterized by large force, great bearing capacity, and high cooling efficiency. It is used extensively for testing big components and complete machines in different industries such as aviation, aerospace, shipbuilding, weapons, automobile, etc.

2. This vibration control system is able to accomplish the tri-axial sinusoidal vibration test, broad-band random vibration test, as well as the classical (semi-sinusoidal, trapezoidal, and post-peak sawtooth) pulse and shock response spectrum test. Configured with a climate chamber, it can also complete the multi-environment combined test.

3. Thus far, various types of water-cooled vibration test system have been provided for option. The exciting force ranges from 50kN to 500kN. The maximum load varies from 800kg to 15000kg.

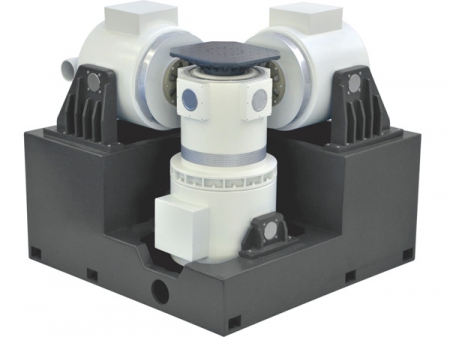

4. This vibration testing system is composed of the shaker, power amplifier, and the cooling unit. It can be optionally installed with Amber, Vibstar, or other control devices.

Prominent Characteristics

1. Wide Frequency Range and High First-Order Resonance Frequency

The water-cooled vibration test system adopts high-strength aerospace composites. This will result in great improvement of the strength, stiffness, and first-order resonance frequency of coil. Also, it allows our product to achieve an international advanced level.

2. High-Reliability and Energy-Efficient Excitation Coil

The excitation coil adopts double-disk winding design to improve its manufacturability and reliability. By adoption of innovative design philosophy, its energy and heating power are enormously reduced.

3. High Water-Cooling Efficiency

The water-cooled vibration test system has remarkably improved its cooling effect, by employing new welding technique as well as the innovative parallel cooling of both coil winding and internal-external short circuit ring.

4. Automatic Adjustment of the Armature Balance Position in Use of MPCS Device

The automatic centering system allows the armature to be always in the balance position during movement. Then, a vibration test that requires the maximum displacement can be conducted smoothly.

5. High Bearing Capacity

A combined air spring supports the suspension system to improve its bearing capacity and also reduce ambient noise significantly.

6. Horizontal and Vertical Tests

The water-cooled vibration shaker with a slip table is ideal for use in horizontal and vertical vibration tests. It can be overturned conveniently by adoption of unique power-driven worm wheel and chain wheel.

7. Safety Properties

Our water-cooled vibration test system is made in compliance with European standard test requirements. Its power amplifier is equipped with emergency stop button to cope with emergencies in time. It is in compliant with safety requirements of both American UL and CE standard.

Model Selection Guide

The shock test equipment may be affected by the overturning moment, inertia moment, center-of-gravity position, and the height of center-of-gravity of specimen. Therefore, its safety factory is recommended to be more than 1.2 times as high as theoretical force.

Performance Parameters

1. High-efficiency Water-cooling Method

2. Sinusoidal excitation force ranges from 50kN to 500kN.

3. Random to sinusoidal excitation force ratio is 1:1.

4. Two-times-of-sine shock force (Three times optional)

5. Displacement peak-to-peak value is 51mm, 76mm.

6. Lightweight armature and Large working table

7. An air spring at trunnion position can offer superb vibration isolation effect.

8. Great bearing capacity of air spring in central room, and extraordinary low-frequency performance

9. An automatic centering system allows the armature to be always controlled in the balance position during movement.

10. Double magnetic circuit design has advantages such as low flux leakage and uniform magnetic field. A slip table can be configured.

11. Horizontal and vertical vibration tests depend on worm wheel transmission to save labor.

12. Available test functions include Sine, Random, and Shock.

13. Efficient and High-Reliability Power Amplifier

Note: The power amplifier can be optionally installed with a remote controller and a LCD screen.

Models

Main Specifications

| System Model | | | ||||||

| Rated Random/Sine Force | 50kN | 60kN | 70kN | 80kN | 80kN | 100kN | 100kN | 120kN |

| Rated Shock Force | 100/150 *kN | 120/180*kN | 140/210*kN | 160/240*kN | 160/240*kN | 200/300*kN | 200/300*kN | 240/360*kN |

| Usable Frequency | 2-2700Hz | 2-2700Hz | 2-2700Hz | 2-2700Hz | 2-2500Hz | 2-2500Hz | 2-2500Hz | 2-2500Hz |

| Maximum Velocity | 2/2.5* m/s | 2/2.5* m/s | 2/2.5* m/s | 2/2.5* m/s | 2/2.5* m/s | 2/2.5* m/s | 2/2.5* m/s | 2/2.5* m/s |

| Maximum Acceleration | 1000 m /s² | 1000 m /s² | 1000 m /s² | 1000 m /s² | 1000 m /s² | 1000 m /s² | 1000 m /s² | 1000 m /s² |

| Maximum Payload | 800kg | 800kg | 800kg | 800kg | 1100kg | 1200kg | 1000kg | 1000kg |

| Maximum Displacement p-p | 51 mm | 51 mm | 51 mm | 76 mm | 51 mm | 51 mm | 51/76* mm | 51/76* mm |

| Resonance Frequency | 2400Hz±5%Hz | 2400Hz±5% | 2400Hz±5% | 2400Hz±5% | 2100Hz±5% | 2100Hz±5% | 2100Hz±5% | 2100Hz±5% |

| System Model | | ||||||

| Rated Random/Sine Force | 160kN | 160kN | 180kN | 180kN | 200kN | 300/240kN | 350/250kN |

| Rated Shock Force | 320/480*kN | 320/480*kN | 360/540*kN | 360/540*kN | 400/600*kN | 600/900*kN | 700/1050*kN |

| Usable Frequency | 2-2200Hz | 2-2200Hz | 2-2200Hz | 2-2200Hz | 2-2100Hz | 2-1700Hz | 2-1700Hz |

| Maximum Velocity | 2/2.5* m/s | 2/2.5* m/s | 2/2.5* m/s | 2/2.5* m/s | 2/2.5* m/s | 2/2.5* m/s | 2/2.5* m/s |

| Maximum Acceleration | 1000 m /s² | 1000 m /s² | 1000 m /s² | 1000 m /s² | 1000 m /s² | 1000 m /s² | 1000 m /s² |

| Maximum Payload | 1600kg | 1800kg | 1600kg | 1800kg | 1600kg | 6000kg | 6000kg |

| Maximum Displacement p-p | 51 mm | 51 mm | 51 mm | 51 mm | 51/76* mm | 51mm | 51mm |

| Resonance Frequency | 1800Hz±5% | 1800Hz±5% | 1800Hz±5% | 1700Hz±5% | 1700Hz±5% | 1600Hz±5% | 1600Hz±5% |

| System Model | | ||||||

| Rated Random/Sine Force | 400/300kN | 500/350kN | 50kN | 60kN | 100kN | 120kN | 200kN |

| Rated Shock Force | 800/1200*kN | 100/150*kN | 120/180*kN | 200/300*kN | 240/360*kN | 400/600*kN | |

| Usable Frequency | 2-1700Hz | 5-1500Hz | 2-2500Hz | 2-2500Hz | 2-2500Hz | 2-2500Hz | 2-2100Hz |

| Maximum Velocity | 2/2.5* m/s | 2 m /s | 2/2.5* m/s | 2/2.5* m/s | 2/2.5* m/s | 2/2.5* m/s | 2/2.5* m/s |

| Maximum Acceleration | 1000 m /s² | 1000 m /s² | 850 m /s² | 1000 m /s² | 1000 m /s² | 1000 m /s² | 1000 m /s² |

| Maximum Payload | 6000kg | 15000kg | 800kg | 800kg | 1000kg | 1000kg | 1600kg |

| Maximum Displacement p-p | 51 mm | 51 mm | 76 mm | 76 mm | 76 mm | 76 mm | 76 mm |

| Resonance Frequency | 1600Hz±5% | 2200Hz±5% | 2200Hz±5% | ||||