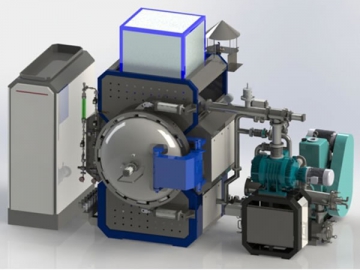

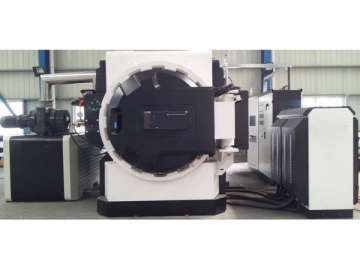

Integrated Vacuum Degreasing and Sintering Furnace

The integrated vacuum degreasing and sintering furnace is the fantastic industrial furnace for degreasing and sintering of powder metallurgies and metal injection molding products including stainless steel, hard alloy, superalloy, high density alloy, ceramic material, magnetic material and NdFeB, etc.

This powder metallurgy equipment offers continuous workflow covering degreasing, pre-sintering, sintering and fast cooling. Consequently, daunting procedures are successfully avoided, such as repeatable transport, heating and cooling to name a few. As a result, our customers benefit from drastically reduced quality failure, labor load, production cycle and cost.

Advantage

1. We adopt independent heating device and temperature measuring component for this integrated vacuum degreasing and sintering furnace, whereupon heat uniformity can be readily achieved and maintained.

2. Our vacuum degreasing furnace is renowned for utilization of high efficiency SWEEP-GASTM degreasing system, covering grease collecting, filtering, rough cleaning and fine cleaning. Unique vapor degreasing system is also available for amazing speed and efficiency.

3. Directional air injection facilitates degreasing effect in a holistic approach. Moreover, constant slight-negative pressure is maintained inside the vacuum sintering furnace, whereby restraining metal volatilization and bettering product compactness and quality.

4. Program temperature controller is employed. PLC is responsible for fully automatic control on temperature and production procedure. Furthermore, our vacuum furnace is applauded for cutting-edge interlocking function, as well as audible and visual alarms on overpressure, overheat or too high water temperature.

5. Internal circulation system adopts high efficiency heat exchanging technique to blow workpiece in multiple directions, whereby providing fast and uniformed cooling effect.

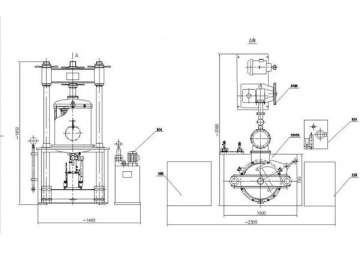

Structure

1. The integrated vacuum degreasing and sintering furnace is available in vertical and horizontal layout.

2. According to furnace temperature and customer’s requirements, the heating component and thermal insulation shield can be made up of graphite, molybdenum or tungsten. Nevertheless, heating component is allowed to be deployed in various units and controlled respectively by PID.

3. Entire hearth can be removed for easy maintenance. Specialized hermetic oven and multi-grade water cooled disc type degreaser are used for superior grease removal and collection.

4. Gas degreasing system is adopted with adjustable flow rate.

5. Ingenious vapor degreasing system eliminates concerns on poor degreasing.

Technical data| Model | |||||

| Rated feeding capacity (kg) | 50 | 100 | 200 | 300 | 450 |

| Rated furnace temperature (℃) | 1550 | 1550 | 1550 | 1550 | 1550 |

| Max. furnace temperature (℃) | 1650 | ||||

| Temperature accuracy(℃) | ≤±5 | ||||

| Rated power (kW) | 60 | 120 | 150 | 180 | 210 |

| Rated voltage of power supply (V) | 380 | ||||

| Rated heating voltage (V) | Depends on design External transformer is available in all design. | ||||

| Max. vacuum degree (Pa) | ≤6.67 (Empty furnace in cool environment) | ||||

| Pressure rising rate (Pa/24h) | ≤50 | ||||

| Working area dimension (W × H × L) (mm) | 300 × 300 × 400 | 300 × 300 × 500 | 450 × 400 × 670 | 450 × 400 × 850 | 600 × 600 × 1000 |

| Temperature control system | Shimaden programmable controller | ||||

| Vacuum system | Rotary vane vacuum pump Roots vacuum pump | ||||

| Degreasing system | Water ring pump | ||||

Retrofit

1. Build-in fast cooling system

2. PLC and touch-screen display

3. Oil diffusion pump is optional, resulting in 6.7×10-4Pa maximal vacuum degree.

4. Heating component and thermal insulation shield with ingenious design and materials as well as 2100°C working temperature.

5. Slight-negative pressure sintering system

6. Vapor degreasing system

- Spark Plasma Sintering Furnace (SPS)

- Vacuum Arc Remelting Furnace

- Dual-chamber Vacuum Oil Quenching Furnace

Related Names

Vacuum Dewaxing and Sintering Furnace | Sintering Kiln | Vacuum Plant