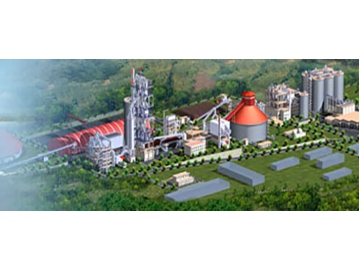

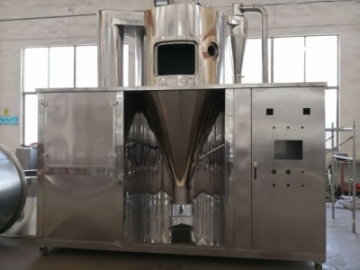

Water Atomization Powder Manufacturing Equipment

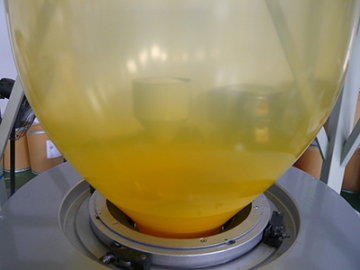

The water atomization powder manufacturing equipment is the commercially progressive methodology in powder metallurgy industry. This kind of powder production machine utilizes high velocity water flow to atomize molten metal into powder particles.

Featuring cost effectiveness and ease of operation, our powder metallurgy equipment is highly recommended for production of iron powder, copper powder, stainless steel powder and alloy powder. Superalloy includes iron-based alloy, nickel-based alloy and silver-based alloy, etc.

Our water atomization powder manufacturing equipment produces 10 to 1,000 kg powder per batch. The metal powder is irregular shaped and oxidized. Decrease in oxygen content needs deoxidizing technique. Moreover, customized non-ferrous metal equipment is also available to cater to your specific requirements on batch capacity and particle size.

Technical data| Model | ||||||

| Water pressure (MPa) | 0-100 | |||||

| Water flow rate (L/min) | 50-800 | |||||

| Feeding capacity (kg) | 30 | 50 | 100 | 300 | 500 | 1000 |

| Max. melting temperature (℃) | 1750 | |||||

| Heating power (kW) | 50 | 80 | 130 | 200 | 260 | 400 |

| Temperature measuring | Infrared, WRe5.26 | |||||

| Tundish heating power (kW) | 10-20 | |||||

| Power supply | 3 phase, 380V, 50Hz | |||||

| Total power (kW) | - | |||||

| Cooling water flow rate (L/min) | 150 | 300 | 400 | 700 | ||

| Water cooling system | Air-cooling tower, water cooling unit, heat exchanger | |||||

| Soft water flow rate (m3/h) | 6-20 | |||||

| Controlling method | Relay or PLC | |||||

| Operation interface | Button or touch screen | |||||

| Data recording | Recorded by 12 data items and displayed in LCD monitor | |||||

| Overall dimension (L×W× H) (mm) | 7500×4000 ×6500 | 7500×4200 ×6500 | 8200×4200 ×6500 | 8200×4500 ×6500 | 8500×4500 ×6500 | 9200×5000 ×6500 |

- Vacuum Degreasing Furnace

- Integrated Vacuum Degreasing and Sintering Furnace

- Vacuum Gas Quench Furnace

Related Names

Water Atomizer | Water Atomizing System | Water Atomization Equipment