Pharmaceutical Aseptic Spray Drying System

Request a Quote

Description

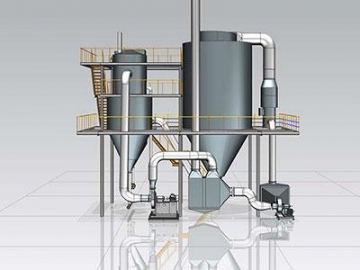

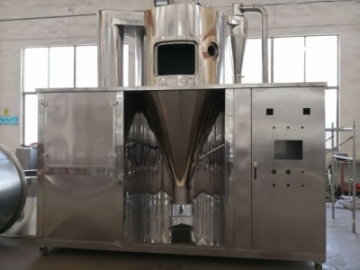

The aseptic spray dryer is a kind of important equipment which can be used to produce injectable powder such as streptomycin, gentamycin sulfate, Kanamycin Monosulfate, Ampicillin and some traditional Chinese medicine injection.

In order to realize sterilization of the aseptic spray dryer, the following improvements are adopted:- After being heated, the external cold air will be filtered by the hot air HEPA filter, so that the air quality can meet the GMP medicine production standards.

- Mix the slurry and filtered water and stir it. Then mix the filtered air and slurry and realize atomization via two-fluid atomization nozzle to get better atomization effect and to meet the requirements of aseptic spraying.

- To prevent powder sticking on the inner wall of the drying tower, the drying tower is equipped with air sweeper which can realize easy cleaning of the powder sticking on the inner wall.

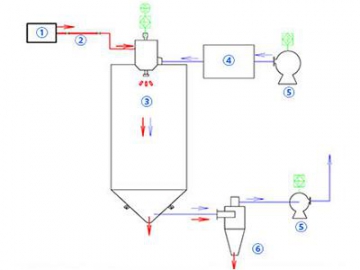

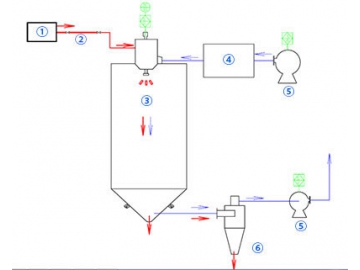

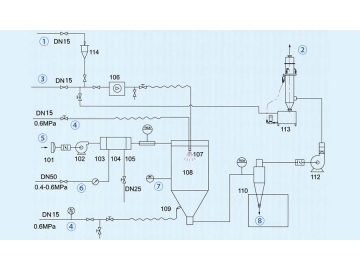

Process flow

① Slurry

② Draining

③ Sterilized water

④ Compressed air

⑤ Cold air

⑥ Steam

⑦ Condensed water

⑧ A septic clean room

The following are some kinds of commonly used aseptic spray dryer for you to choose from, you can also make some related improvements on the base of various types:

| Item | WPG | |||||

| 12 | 16 | 20 | 25 | 30 | 35 | |

| Inlet Temp (℃) | 180-220 | |||||

| Outlet Temp (℃) | 80-100 | |||||

| Atomizer method | rotary atomizer / two fluid atomizer | |||||

| Heat resource | Electrical heating | Steam +electricity | Steam +electricity | Steam +electricity | Steam +electricity | Steam +electricity |

| Power (kw) | 21 | 36 | 60 | 72 | 108 | 135 |

| Disinfecting method | Clean hot air sterilization | |||||

| Sanitary grade | 100K | |||||

| Diameter (mm) | 1200 | 1600 | 2000 | 2500 | 3000 | 3500 |

| Height (mm) | 3000 | 5200 | 6000 | 7000 | 8000 | 9000 |

| Material | Texture which directly contacts the material is 316L, the others are SU304. | |||||

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos