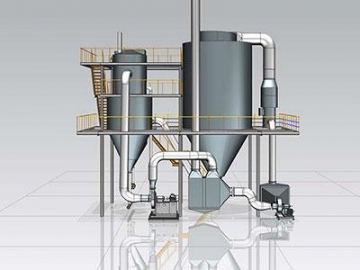

Fluid Bed Processor with Top spraying system for Agglomeration and Granulation

The pressure atomizer spray drying machine will compress the feeding material into the nozzle atomizer on top of the drying tower, so that the material will be atomized into tiny fog-drops. They will fall down from the top of the tower along with hot air so that it can be dried. Thus, the slurry with higher solid content can be atomized and granulated by pressure. Then it will be dried to form spherical particles. The dried product features good free fluidity.

The pressure atomizer spray drying machine will pump the feeding material into the drying room by diaphragm pump (control pump). Meanwhile, the cold air from the outside will be heated after being filtered by the filtering system. Then, conduct atomization of the feeding material and filtered air via nozzle atomizer. Around 95-98% water content will be instantly evaporated in the drying room. Only ten to dozens of seconds are needed to accomplish drying. The pressure atomizer spray drying machine adopts automatic slurry washing device and spray gun anti-blocking technology so that it is especially suitable for drying of heat sensitive material.

Besides, this spray drying machine can be equipped with additional fine powder collection system according to users’ requirements to prevent material waste.

Food industry drying

Pharmaceutical industry drying

Plastic resin drying

Detergent drying

Chemical industrial product drying

Ceramics drying etc.

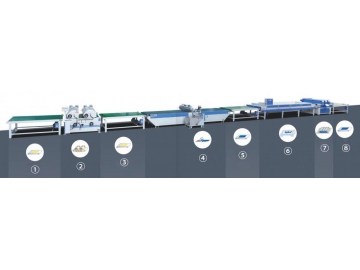

The following are some kinds of commonly used pressure atomizer spray drying machine for you to choose from, you can also make some related improvements on the base of various types:

| Type/item | YPG -6 | YPG -12.5 | YPG -25 | YPG -50 | YPG -65 | YPG -100 | YPG -200 | YPG -300 | YPG -500 | YPG -600 | YPG -1000 | YPG -2000 | YPG -3000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Water evaporation quantity (kg/h) | 6 | 12.5 | 25 | 50 | 65 | 100 | 200 | 300 | 500 | 600 | 1000 | 2000 | 3000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Spraying method | Low pressure nozzle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Spraying pressure (MPa) | Bottom spraying type: 0.6~4.0 ; top spraying type 1.0~1.5 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tower diameter(m) | D |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tower height (m) | H | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Floor area length (m) | M | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Floor area width (m) | L | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Note: the water evaporation quantity is related with material features, solid content and hot air inlet and outlet temperature. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Besides of providing various kinds of drying equipment sets, Jiangsu Xiandao also provides related supporting services such as designing and arranging according to the factory conditions, providing installation or guidance services, after-sale technical guidance and maintenance guidance etc. If you have interest on our equipment, please tell us the No. you want, we will try out best to satisfy your requirements.