Automatic Pusher Sintering Furnace

The automatic pusher sintering furnace is presented as continuous powder metallurgy equipment. This industrial sintering furnace is greatly recommended for powder reduction, as well as sintering of powder metallurgy products, especially stainless steel.

Advantage

1. Reliable

Outstanding automation delivers superior reliability. You will enjoy intuitive mimic panel, comprehensive alarm system and power-off protection, as well as automatic control on temperature and procedure. In addition, sensors are supplied by famous enterprises home and abroad to minimize failure.

2. Economical

Our automatic pusher sintering furnace is fitted with ultra power efficient structure, demonstrating excellence in terms of thermal insulation, energy storage and heat loss. Comparing to competitors on market, our stainless steel sintering equipment is amazingly distinguished by lower consumption in water, electricity and gas.

3. Flexible

We utilize a dual-gate structure at inlet and outlet unit to form exchanging room. Constant nitrogen is charged into the room to exchange air, thus preventing outside air from flowing into furnace. This feature makes our continuous powder sintering equipment suitable for applying heat treatment to high temperature and oxidizable workpiece, and have less requirements on atmosphere compared to other industrial sintering furnaces.

Structure

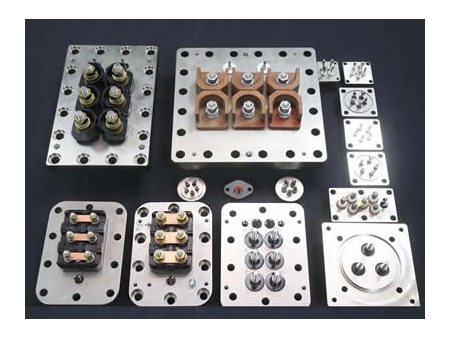

1. The entire automatic pusher sintering furnace is combined with furnace body, feeding oven pushing device, automatic charging and discharging track, as well as temperature control system.

2. Furnace shell and cover are mainly welded by folded steel plate and profile steel, offering industrial beauty.

3. Modular all fiber needlefelt carpet is ceiling suspended on furnace top plate, ensuring stable thermal insulation and thermal shock resistance, as well as low energy storage and heat loss. What’s more, power consumption of induction furnace, temperature rise and heating uniformity are all better than national standard level. As a result, furnace lining enjoys longer service life.

4. This automatic pusher sintering furnace is endowed with intelligent temperature controller supplied by Shimaden. This device utilizes self-adjustment and standard PID controller, whereby prohibiting temperature overshoot. Digital display readily realizes functions of selection, setting and configuration.

Main heating unit involves the combination of SCR series 3 phase thyristor power controller. In stead of traditional electrical on-off controlling mode, this controller utilizes continuous control not via on-off mode, but on the basis of temperature to automatically adjust heating power. In addition, high accuracy and no noise generation can be achieved in temperature control for high power with no influence to internal power system.

Technical data| Model | |||

| Rated heating temperature (℃) | 1250℃ | ||

| Hearth size in heating zone (W × H) (mm) | 220 × 100 | 320 × 100 | 430 × 120 |

| Number of heating zone | 5 | 6 | 7 |

| Gas consumption | 6m3/h | 9m3/h | 12m3/h |

| Rated heating power (kW) | 70kW | 120kW | 150kW |

| Hearth material | Heat resistant stainless steel 310S/high temperature ceramic tube | ||

| Heating component | High temperature resistance wire/silicon carbon rod or fuel | ||

| Furnace body structure | Normal/all ceramic fiber | ||

| Overall dimension (W × H × L) (mm) | 1380 × 1700 × 11500 | 1500 × 1700 × 13600 | 1750 × 1700 × 15000 |

| Temperature control | Shimaden temperature control with PID | ||

Retrofit

1. Fuel degreasing system in RBO (rapid burn-off) unit

2. Forced gas quenching system

3. Automatic feeding system with circle track

4. Front and rear exchanging room

5. PLC and touch screen control system

- Pusher Reduction Furnace

- High Temperature Graphite Furnace

- PSA Nitrogen Generator

Related Names

Sintering Equipment | Automatic Pusher Kiln