Vacuum Brazing Furnace

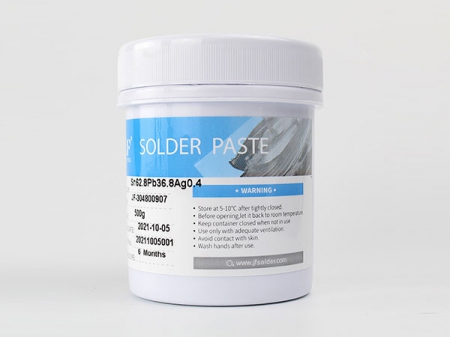

The vacuum brazing furnace is mainly applicable for brazing of aluminum, copper and stainless steel used for parts of airplane, automobile, electronic communication equipment, household appliance, heat exchanger and radiator, etc.

Heating in vacuum environment removes grease and oxidation on surfaces of workpiece. Therefore, output products that our industrial furnace generates are endowed with brilliant surfaces, requiring no brazing flux or washing.

Advantage

1. Single chamber, interior heating, cool wall, vertical and horizontal layout are all available with compacted structure. Customers avail from various choices to fit their specific application needs.

2. Heating chamber of this copper brazing furnace is fitted with temperature control deployed in several zones. Hence, outstanding heat uniformity is aggressively guaranteed.

3. Well-conceived thermal insulation shield is available in our atmosphere brazing furnace, whereby promoting heat efficiency.

4. Vacuum system of this single chamber vacuum brazing furnace comes with specialized condensation filter to eliminate pollution that brazing flux vapor brings to vacuum pump.

Structure

1. Our vacuum brazing furnace is available as horizontal and vertical layout.

2. Based on heating temperature and requirements from customers, heating component and thermal insulation shield can be made up of graphite, molybdenum, or tungsten. Furthermore, heating component is deployed in various heating zone and is controlled independently by PID.

3. Hearth of this vacuum brazing furnace is removable for convenient maintenance. Gas charging system is ready to fill protective gas or working gas into hearth at changeable flow rate.

4. Internal circulation cooling system enhances cooling efficiency and reduces working time.

Technical data| Model | |||||

| Rated feeding capacity (kg) | 50 | 100 | 200 | 300 | 400 |

| Max. temperature (℃) | 1350 | ||||

| Temperature accuracy(℃) | ≤±5 | ||||

| Rated power(kW) | 50 | 90 | 120 | 150 | 180 |

| Rated voltage of power supply (V) | 380 | ||||

| Rated heating voltage (V) | Depends on design Front transformer is available in every design. | ||||

| Max. vacuum degree (Pa) | ≤6.67 (Empty furnace in cool status) | ||||

| Vacuum pressure rising rate (Pa/24h) | ≤50 | ||||

| Air cooling pressure | ≤0.1Mpa | ||||

| Working zone size (W × H × L) (mm) | 300 × 300 × 400 | 300 × 300 × 500 | 450 × 400 × 670 | 450 × 400 × 850 | 600 × 600 × 1000 |

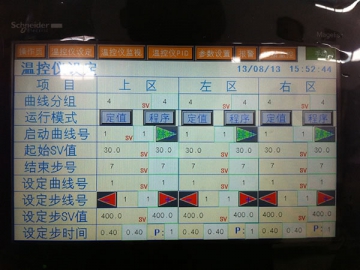

| Temperature control | Shimaden programmable controller | ||||

| Vacuum control | Rotary vane vacuum pump Roots pump | ||||

Retrofit

1. Built-in fast cooling system

2. PLC and touch screen

3. Based on requirements on vacuum degree, oil diffusion pump can be added and maximal vacuum degree reaches 6.7×10-4 Pa.

- Gas Atomization Powder Manufacturing Equipment

- Pusher Reduction Furnace

- Glass Melting Furnace

Related Names

Brazing Machine | Copper Brazing Furnace | Vacuum Furnace