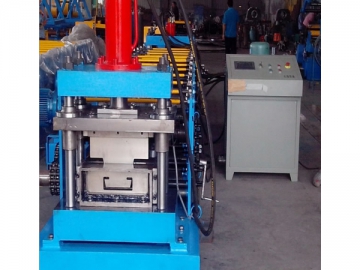

C Channel Rolling Machine

We use premium raw materials for the production of our C channel rolling machine. With the help of our production equipment, we are able to serves for large orders from our customers. The roll forming lines are widely used for making rims. The products manufactured by this kind of metal forming equipment can be used as the supporting structures of roofs and walls of medium or large civil buildings.

The C channel rolling machine, as a piece of steel processing equipment, comes with automatic flying saw for the drilling operations, while the whole operation is quite simple.

Main technical parameter

1.Product size: 9500*2050*1300mm

2.Production speed: 0-12m/min

3.Forming lanes: 13 group

4.Target material: alloy steel GCR15 (bearing steel)

5.Frame materials: 300H steel (the side plate is assembled with 20mm steel which has been milled)

6.Quenching hardness of roll: HRC58-62

7.Roller quenching depth: 8mm

8.Roller quenching method: overall quenching in the salt bath furnace

9.Roller spindle: premium 40CR

10.Roll diameter: 80mm

11.Roll thermal treatment: quenching and tempering treatment

12.Roller bearings: deep groove ball bearing 212

13.Rolling type: 80-300

14.Rolling thickness: 1-3mm

15.Configuration power: 15KW

16.Power of the converting motor: 2*1.5KW

17.Driving motor: M6-450 hydraulic motor

18.Fuel pump model: 40MCY14-1B plunger pump