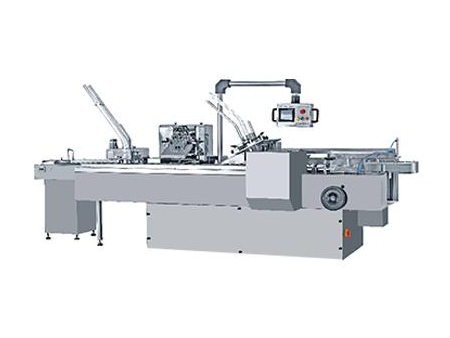

Automatic Gable Top Carton Filling Machine

Automatic Gable Top Carton Filling Machine

image001.jpg、image003.jpg

Our automaticgable top carton filling machine controlled by single-line single-body gearbox is specially designed for shaping, filling and sealing gable top cartons. Itcan be used to fill various kinds of liquid foods, such as milk, yoghourt,fresh cream, juice, etc. Combinedwith other optional devices, this paper box filling and sealing machine is also suitable for fillinghigh-viscosity, granular or solid foods and other products.

The CAP-PAC capping machine can be installed to this automatic gable top carton filling machine to weld plastic caps onto the preserved opening of the gablecarton by ultrasonic wave.

Featuresof Automatic Gable Top Carton Filling Machine

1. Equipped with a PLC control system, thisautomatic gable top carton filling machine can be easily operated by only oneoperator.

2. Compact structure makes this automatic carton packing equipment space saving.

3. It is of low noise and low energy consumption.

4. With a fine regulating device, our automatic gable top carton filling machine has high filling accuracy.

5. The production speed, filling volume, carton height can be adjustedaccording to practical need. It takes little time to change the cartons ofdifferent sizes for being filled.

6. This gable top paper boxpackaging equipment adopts standard parts and localized substitutes.

7. Our product conforms to the U.S. Grade 3A Standard. Its maintenance cost islow.

8. Considerate after-sales service and sufficient spare parts supply areavailable.

Compositionof Automatic Gable Top Carton Filling Machine

1. Stainlesssteel housing

2. Mechanicaldriving system, automatic loading and unloading system

3. Touch-screenPLC controller

4. Electriceye identification device

5. Automatic detection switch detect carton shortage and filling materialshortage

6. Polyethylester shield,electronic self-locking door switch

7. Stainless steel cylinder and liquid level pneumatic valve control system

8. Standard filling sprayer and fillingfine regulator

9. Top andbottom heater

10. Water-cooling molding bar and sealing clamp

11. Electronic speed regulator forregulating speed from standard speed to zero

12. Foamremoving motor and vacuum generator

Optional Device for Automatic Gable Top Carton Filling Machine

1. Automaticlubrication system

2. HEPA air filter

3. Power supply system (other than the above)

4. CAP-PAC capping machine

5. Independent CIPcleaning water feeding system

6. Productconveying device

7. Auxiliary fillingsystem (Different filling sprayers and auxiliary parts are available fordifferent products, such as those lubricating oil or edible oil that are viscous or contains granularor fibrous substances.)

Technical Parameter

| Model | WDB-1000 | WDB-2000 | WDB-3000 |

| Production capacity | 250 or 500mL carton: 1000pcs/h | 250 or 500mLcarton: 2000pcs/h | 250 or 500mL carton: 3000pcs/h |

| Air consumption | 85psi/7bar, | 85psi/7bar, | 85psi/7bar, |

| Cooling water | 50°F/10°C, 2.0gpm/7.6 | 50°F/10°C, 2.0gpm/7.6 | 50°F/10°C, 2.0gpm/7.6 |

| Power consumption | 12.5kW | 14.5kW | 18.5kW |

| Control mode | Semi-auto electrical control | Semi-auto PLC control | Fully-auto PLC control |

| Machine dimension | 3500×1500×2800mm | 3500×1500×2800mm | 3500×1500×2800mm |

| Machine weight | 2440kg | 2450kg | 2460kg |