Continuous Overhead Rail Shot Blast Machine

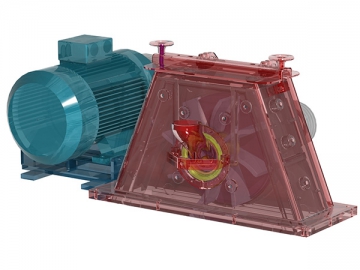

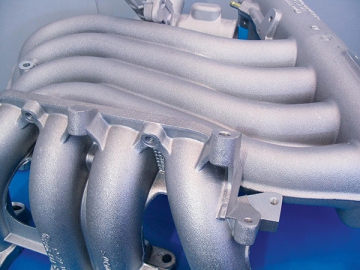

The continuous overhead rail shot blast machine helps to remove sand, oxidized layer and other contaminants away from castings, and this is achieved by rotating and stopping hooks at different points in the blast cabinet during shot blasting process. So, this continuous shot blasting machine is often adopted to deal with swing bolster, side frame, coupler, coupler yoke and other automotive parts, and it also works well for castings and small parts.

System Configuration

Our continuous overhead rail shot blast machine is an integration of many leading-edge components, and here are some details.

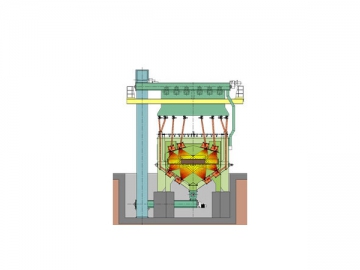

The blast cabinet, pre-blastroom and post-blastroom are made by welding 10-mm-thick steel plate and profile steel to guarantee their superior strength, and the blast cabinet is covered by an acoustic enclosure for better noise control.

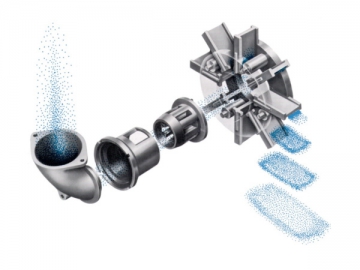

2. Blast Wheel AssemblyThe blast wheel assembly consists of blast wheel, turbine, bed plate and so on. For this overhead rail shot blast machine, Q034Z direct driven centrifugal blast wheel is utilized, and its location and angle are precisely calculated by computer-aided 3D dynamic simulation to provide thorough cleaning for metal surfaces. In addition, the blast wheel is housed inside an acoustic enclosure, but it allows easy access to facilitate maintenance.

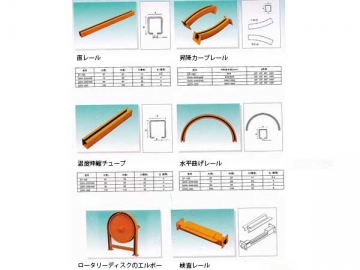

3. Abrasive Reclamation SystemFor this abrasive blast equipment, its abrasive reclamation system is formed by screw conveyor, bucket elevator, sand separator, pneumatic valve (for abrasive transport), abrasive delivery chute, automatic compensation unit and so on.

4. Abrasive Cleaning System

Our continuous overhead rail shot blast machine is equipped with an abrasive blower to clean remaining abrasives and dust after shot blasting. In this way, neither abrasive nor dust will be carried along with work pieces to undergo painting treatment, and excellent painting effect is guaranteed.

Both the platform and ladder are manufactured as per national standards and relevant safety specifications, whilst patterned steel sheets and safety barriers are also employed by the platform to offer extra protection for operators.

6. Dust Removal SystemOur continuous overhead rail shot blast machine’s dust removal system is mainly made up of ventilation pipeline, cyclone dust collector, cartridge filter and exhaust blower, and it makes use of three stage dedusting process to realize high dust removal efficiency which is over 99.9%. More specifically, the ventilation pipeline gives air at different positions to uniformly ventilate blast cabinet without any dead zone, and the cartridge filter, supplied by Donaldson Company, Inc., uses high-quality filter paper (with good flexibility, high strength, long life, etc.) to form its filter element.

7. Electrical Control SystemControlled by a PLC controller, the electrical control system adopts high-quality electrical devices to offer stable performance, and it has inter-locking, self-locking and failure warning functions to make sure that ourmetal surface cleaning equipment will always work under a safe condition.

Ordering Information

The continuous overhead rail shot blast machine could be tailored in max. work piece size, number of work station, number of blast wheel, blast cabinet size and other aspects.

| Item | Unit | | | |

| Max. work piece size | mm | Ф800×1200 | Ф1000×1500 | Ф1000×2500 |

| No. of workstation | - | 2 | 2 | 6 |

| No. of blast wheel | kg | 4 | 4 | 6 |

| Abrasive consumption | kg/min | 4×250 | 4×250 | 6×250 |

| Power of blast wheels | kW | 4×15 | 4×15 | 6×15 |

| Max. load capacity of hook | kg | 300 | 500 | 1000 |

| Productivity | Hook/hour | 30~60 | 30~60 | 40~60 |

| Blast cabinet size | mm | 7680×2000×2900 | 7680×2000×2900 | 7680×2000×3800 |

| Air requirement | m3/h | 17000 | 19000 | 19000 |

| Total power | kW | 73.15 | 73.15 | 114.72 |