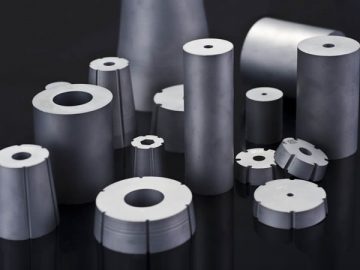

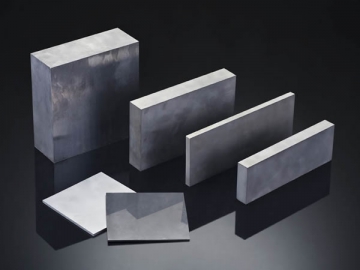

Tungsten Carbide Blanks (for Cold Heading Dies)

As a custom carbide products manufacturer, our tungsten carbide blank manufacturing technology is always in the world's first-class level. This page mainly introduces you our range of tungsten carbide preforms for producing cold heading dies.

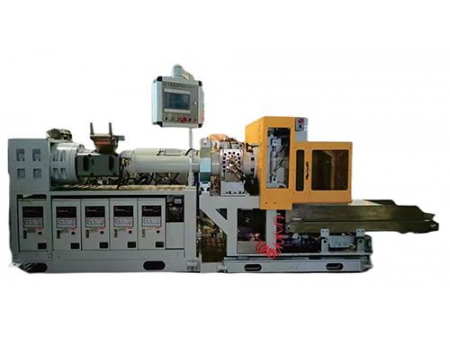

Cold heading technology can reduce the remain of the blank and shorten the time of manufacturing and processing. It is indeed one of the most effective and beneficial methods, and thus has competently substituted other methods for metal cutting and machining in the industries of automobile, bicycle, appliance, machine manufacturing, etc. In order to meet the increasing demand for tungsten carbide dies in cold heading process, we have especially developed this series tungsten carbide blanks for cold heading die manufacturing.

Designations and Technical Specifications| Designations | ||||||||

| Cobalt Content (%) | 12 | 15 | 15 | 20 | 21 | 20 | 22 | 25 |

| WC Particle Size (μm) | 2-3 | 2-3 | 3-6 | 2-6 | 2-6 | 3-6 | 6-9 | 6-9 |

| Density (g/cm3) | 14.30 | 13.90 | 13.88 | 13.40 | 13.30 | 13.55 | 13.38 | 13.15 |

| Hardness (HRA) | 88.5 | 88.2 | 86.5 | 85.2 | 84.5 | 84 | 82.5 | 81.5 |

| Crosswise Tensile Strength (MPa) | 3,400 | 3,300 | 3,200 | 3,200 | 3,000 | 2,700 | 2,700 | 2,600 |

| Breaking Tenacity (K1c, MPam1/2) | 12 | 13.59 | 18.39 | 19.34 | 20.68 | 20.98 | 26.34 | 25.79 |

| Application Range | Strong beam mold | Stainless steel screw mold with the bore< φ2.1 | Stainless steel screw mold with the bore> φ2.1 | Large size mold with straight hole, triangle die, etc. | Six die and die nut | Die nut and Hurstfull-tungsten | Impact resistant forging die and Hurstfull-tungsten | |

Features of Tungsten Carbide Blanks

Extended lifespan

Via precision control on Wolfram Carbide (WC) particle size, our cold heading die blank is provided with reduced plastic deformation during load bearing as well as improved compressive strength and the breaking tenacity. Thus, the tungsten carbide blank can effectively extend the lifespan of resulted dies, by delaying the occurrence or extension of cracks.

Substantially reduced chance of fracturing

Engineered from single crystal WC, our tungsten carbide blank comes with enhanced combinability of the crystal structure, and enhanced cobalt performance as well. This effectively prevents fracturing of tungsten carbide dies.

Higher corrosion resistance and electro-processing performance

The enhanced cobalt performance tremendously increases the corrosion resistance of the tungsten carbide blanks. Consequently, the carbide blank for cold heading dies is suitable for being electro processed.

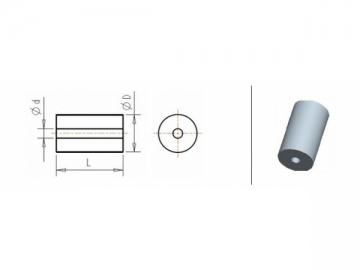

Screw Mold Blank

This series of tungsten carbide blanks is used to produce cold heading dies for screw production.

| Specification | Outer Diameter (mm) | Tolerance (mm) | Inner Diameter (mm) | Tolerance(mm) | Length (mm) |

| 8 | 8.3 | 0-0.15 | 0,1 | ≤3.0, -0.1-03.0-6.0, -0.2-0.056.0-9.0, -0.4-0.109.0-12.0, -0.5-0.1512.0-15.0, -0.6-0.2015.0-20.0, -0.8-0.25>20.0, -1.5-0.5 | ≤30 |

| 10 | 10.3 | 0-0.20 | 0, 0.7, 1.0, 1.5, 2.0, 2.5, 3.0 | ≤40 | |

| 10.8 | 0-0.20 | 0, 0.7, 1.0, 1.5, 2.0, 2.5, 3.0 | ≤45 | ||

| 12 | 12.3 | 0-0.20 | 0, 0.7, 1.0, 1.2, 1.4, 1.5, 1.7, 1.8, 2.0, 2.2, 2.5, 2.7, 3.0, 3.2, 3.4, 3.5, 3.7, 3.8, 4.1 | ≤45 | |

| 12.8 | 0-0.20 | 0, 0.7, 1.0, 1.2, 1.4, 1.5, 1.7, 1.8, 2.0, 2.2, 2.5, 2.7, 3.0, 3.2, 3.4, 3.5, 3.7, 3.8, 4.1 | ≤45 | ||

| 13 | 13.3 | 0-0.30 | 0, 1, 1.5, 2.0, 2.5, 3., 4.6 | ≤45 | |

| 15 | 15.3 | 0-0.30 | 0, 0.7, 1, 1.2, 1.4, 1.5, 1.7, 2.0, 2.2, 2.5, 3.0, 3.2, 3.3, 3.4, 3.5, 3.8, 4.0, 4.3, 4.6, 4.8, 5.0, 5.4, 5.6 ,6.6 | ≤50 | |

| 15.8 | 0-0.30 | 0, 0.7, 1, 1.2, 1.4, 1.5, 1.7, 2.0, 2.2, 2.5, 3.0, 3.2, 3.3 3.4, 3.5, 3.8, 4.0, 4.3, 4.6, 4.8, 5.0, 5.4, 5.6, 6.6 | ≤50 | ||

| 16 | 16.3 | 0-0.35 | 1, 1.5, 2.0, 2.5, 3., 3.9, 3.5 | ≤50 | |

| 18 | 18.3 | 0-0.35 | 0, 1.0, 1.2, 1.4, 1.5, 1.7, 2.0, 2.2, 2.5, 2.7, 3.0, 3.4, 3.5, 3.9, 4.6, 5.0, 5.6, 6.6, 7.4, 8.7, 9.3 | ≤60 | |

| 20 | 20.3 | 0-0.40 | 0, 1.0, 1.4, 1.5, 2.0, 2.5, 3.0, 3.4, 3.5, 3.9, 4.6, 4.8, 4.9, 5.0, 5.3, 6.0, 6.6, 7.4, 8.6 | ≤70 | |

| 22 | 22.3 | 0-0.40 | 0, 1.0, 1.5, 2.0, 2.5, 3.0, 3.4, 3.5, 3.9, 4.5, 5.0, 5.3, 6.0, 6.4, 6.6, 6.9 | ≤70 | |

| 25 | 25.3 | 0-0.40 | 0, 1.0, 1.5, 2.0, 2.5, 3.0, 3.4, 3.5, 3.9, 4.1, 4.5, 5.0, 5.6, 6.0, 6.4, 6.9, 7.2, 7.9, 8.2, 8.6, 9.0, 9.5, 10.1, 10.4, 11.3, 12.0 | ≤80 | |

| 30 | 30.3 | 0-0.40 | 0, 0.7, 2.0, 2.5, 3.0, 3.4, 3.5, 3.9, 4.5, 4.8, 5.0, 6.0, 6.4, 7.2, 7.3, 8.0, 8.9, 9.3, 10.2, 10.4, 10.5, 11.2, 12.0, 12.7, 13.4, 13.9, 14.7, 15.4 | ≤90 | |

| 35 | 35.3 | 0-0.45 | 0, 3.0, 3.4, 3.5, 3.9, 4.5, 5.0, 5.4, 5.6, 6.0, 7.2, 8.2, 9.3, 10.2, 10.4, 10.9, 11.8, 12.6, 13.4, 14.2, 14.7, 15.4, 16.0, 16.6, 18.7, 19.9 | ≤100 | |

| 40 | 40.3 | 0-0. 45 | 0, 2.5, 3.0, 3.4, 3.9, 4.5, 5.0, 5.6, 6.0, 6.9, 8.2, 9.0, 9.3, 10.1, 10.4, 10.9, 11.3, 11.8, 12.6, 13.4, 14.2, 15.2, 15.6, 16.0, 16.6, 17.4, 18.0, 19.2, 19.7, 21.4, 23.4 | ≤100 | |

| 45 | 45.5 | 0-0. 50 | 0, 5.0, 6.0, 6.9, 7.9, 8.9, 10.4, 10.7, 10.9, 11.3, 12.0, 13.0, 14.1, 15.1, 15.6, 16.0, 17.2, 18.0, 19.3, 19.5, 23.3, 23.9 | ≤100 | |

| 50 | 50.9 | 0-0. 60 | 0, 4.3, 9.9, 10.4, 11.8, 13.4, 15.5, 16.0, 18.0, 19.7, 21.7, 23.9, 25.0 | ≤100 | |

| 55 | 55.8 | 0-0.60 | 3.9, 15.6 | ≤100 | |

| 60 | 60.8 | 0-0.6 | 0, 15.6, 24.6 | ≤50 |

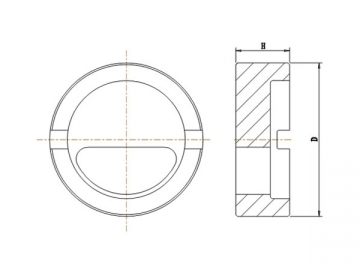

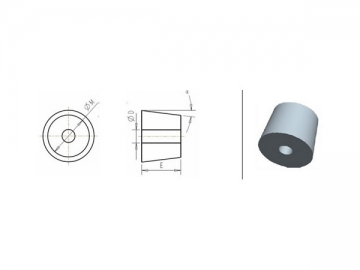

Nut Mold Blank (Round)

These tungsten carbide blanks are used to produce cold heading dies for round nut production.

| Small Circle's Outer Diameter(mm) | Tolerance (mm) | Inner diameter (mm) | Tolerance (mm) | Length (mm) |

| ≤30 | ±0.2 | 2.5-25 | 2.5-3.0, -0.1-0 3.0-6.0, -0.2-0.05 6.0-9.0, -0.4-0.10 9.0-12.0, -0.5-0.15 12.0-15.0, -0.6-0.20 15.0-20.0, -0.8-0.25 >20.0, -1.5-0.5 | 10-60 Note: There is finishing allowance according to customers' requirement. |

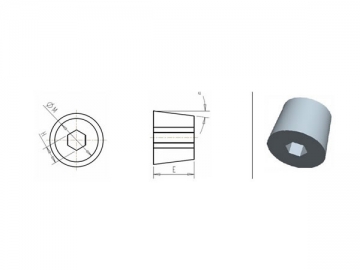

Nut Mold Blank (Hexagon)

This line of tungsten carbide blanks is used to produce cold heading dies for hex nut production.

| Small Circle's Outer Diameter(mm) | Tolerance (mm) | Inner diameter (mm) | Tolerance (mm) | Length (mm) |

| ≤15 | ±0.2 | 3.5, 4.5, 5.5, 6, 6.5 | 3.5-6.0, ±0.1 6.0-9.0, ±0.15 9.0-12.0, ±0.2 12.0-15.0, ±0.25 15.0-20.0, ±0.3 >20.0, ±0.35 Note: There is finishing allowance according to customers' requirement. | 10-60 |

| 15-20 | ±0.2 | 5.5, 6.0, 6.5, 7.0, 7.5, 8.0, 8.5, 9.0, 9.5, 10.0, 10.5, 11.0 | ||

| 20-25 | ±0.2 | 6.5, 7.0, 7.5, 8.0, 8.5, 9.0, 9.5, 10.0, 10.5, 11.0 | ||

| 25-30 | ±0.2 | 9.5, 10.0, 10.5, 11.0, 11.5, 12.0, 12.5, 13.0, 13.5, 14.0, 14.5, 15.0, 16.0, 16.5, 17.0, 17.8, 18.0, 18.2, 18.5, 19.0, 19.5 | ||

| 30-35 | ±0.3 | 11.5, 12.0, 12.5, 13.0, 13.5, 14.0, 16.0, 16.5, 17.0, 17.8, 18.0, 18.2, 18.5, 19.0, 19.5 | ||

| 35-40 | ±0.4 | 18.5, 19.0, 20, 20.5, 21.0, 21.5, 22.0, 22.8, 23.0, 23.5, 24.5, 25.2 | ||

| 40-45 | ±0.4 | 20.0, 20.5, 21.0, 21.5, 22.0, 22.8, 23.0, 23.5, 24.5, 25.2, 28.0, 34.8, 35.8 | ||

| 45-55 | ±0.4 | 28.0, 34.8, 35.8 |