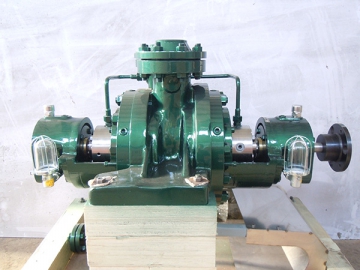

API610 BB5 Pump (Double Casing Radial Split Pump)

Properties

Flow rate : 0 – 850m3 /h

Head : 600 – 2450m

Materials: Cast iron, SS304, SS316, SS316Ti, SS316L, CD4MCU

Temperature: -30°C -425°C

As a reliable manufacturer of pumping equipment, our company has designed and manufactured many API610 pumps among which this API 610 BB5 Pump D is a multi-stage double-casing centrifugal pump of a radial split structure. Manufactured strictly according to the API610 standard, this multi-stage centrifugal pump, equipped with a guide vane, adopts a pump core that can be removed for maintenance from pump barrel casing (outer casing) without bothering users to dismantle pipelines, vertical suction and discharge nozzle. To be more specific, as for a smaller pump of this type, the internal panelized components could be removed only after users dismantle the mechanical seal housing and bearing housing. As for the larger one, all the above mentioned parts could be removed and installed at the same time. This scientific design also ensures the hydraulic thrust to be balanced throughout the pump’s operation.

This industrial centrifugal pump is equipped with a quality barrel which contains a drain cover. The barrel could be designed with a cast structure or forged structure according to the rated pressure of the flange. The barrel body and cover are connected by double studs and nuts (flange nuts are applicable as well), making it easier for users to install or dismantle the barrel. Given this considerate design, the pump could operate smoothly under any pressure and discharge pressure. Meanwhile, as the upper part and lower part of its inner casing are symmetric, the entire pump enjoys a uniform temperature when outside temperature changes.

At the same time, its impellers, which have gone through the double-sided dynamic equilibrium treatment and been installed in pairs, could transmit the axial force to the shaft and the later would get expanded as a reaction without generating any abnormal pressure. To ensure the best performance of this API610 BB5 pump, we have equipped multi-stage centrifugal pump with quality rotors which have gone through the test for dynamic equilibrium and TIR test. The rotors, of scientific design, enjoy a quite high rotating speed. If necessary, they could be arranged back to back. Given this fact, this API BB5 pump requires less maintenance efforts.

Structures of API610 BB5 Pump

1. This double-casing centrifugal pump is manufactured according to technical standards for non-cartridge seal. Some subtypes of this model are designed with cartridge seal.

2. This API610 BB5 pump enjoys a double-volute structure which could keep the hydraulic pressure balanced.

3. There is only one pressure seal which leads to the outside and another full pressure seal used for suction.

4. This centrifugal pump could ensure minimum pressure attenuation during the running clearance.

5. The radial shaft sleeve and tilting pad could support the bearings.

6. We could provide you customized floors for pump cover as well as pumping equipment according to contract.

7. This radial split centrifugal pump adopts the mechanical seal—double-sided or single-sided and an auxiliary seal-non-contact dry gas seal.

8. The hydraulic design between each two impellers and that between the impeller and guide vane are totally different from each other. The close type impellers adopt the key-drive.

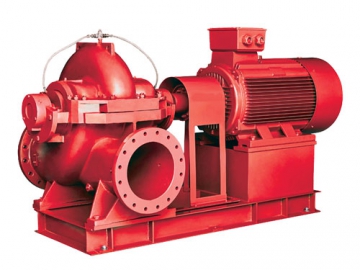

Application of API 610 BB5 Pump

This API centrifugal pump has been widely used in oil refinery, petrochemical production, oilfield injection, terminal projects , hydro-treating, water supply for heaters and coolers, hydro-cracking, visbreaking, hydrocarbon processing and other industrial productions.