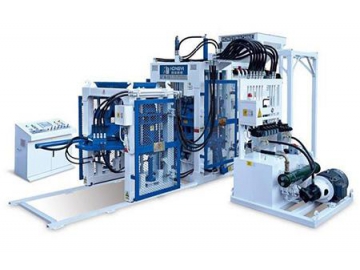

QT12-15 Automatic Block Making Machine

QT12-15 automatic block making machine adopts intelligent control which allows ease of operation by users from the main control table. In a regular 8-hour day, model QT12-15 block machine generally pounds out a maximum of 24000 blocks.

Features of QT12-15 Automatic Block Making Machine

1. Steel used to construct this automated concrete block machine totally meets related national industry standards. Components are of industry-leading brands. The electrical system is from German Schneider Company and the solenoid valve from Japanese YUKEN. Properly designed electric circuit ensures the service life of the entire electrical system.

2. Advanced welding technology uses carbon dioxide as a shield gas during welding. The resultant weld is solid, vibration resistant, and able to withstand 6 to 8 years of trouble-free use.

3. Placement of concrete mix is done fast, thanks to the use of German MASA concrete feeding system on the automatic block making machine. The system works best with aggregates and sands, as it fills them into the mold, controls the filling height, and ultimately ensures the final product height is consistent. The direction guide system is from Danish KVM Company. Thanks to the synchromesh gearbox and tamper head guide, it is easy to control the position of the tamper head in a precise manner. The copper sleeve on the guide post (or column) is wear-resistant.

4. Computer-automated material storage system controls the feeding of concrete mix without being affected by external factors or internal material stress, thereby ensuring consistent supply of material to the automatic block making machine. The result is that finished concrete blocks do not vary in strength.

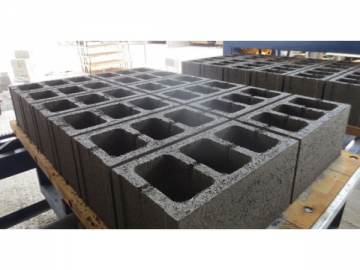

| Brick Specifications | BrickSamples | pcs/mold | pcs/h | pcs/8h | 1 year (300 days) |

| Blocks 390×190×190mm 71pcs/m3 | 12 | 2160 | 17280 | 73014m3 | |

| Blocks 390×100×190mm 135pcs/m3 | 21 | 3780 | 30240 | 67200m3 | |

| Dutch Bricks 200×100×60mm 50pcs/m2 | 42 | 7560 | 60480 | 362880m2 | |

| Dog-bone Pavers 200×165×60mm 30pcs/m2 | 28 | 5040 | 40320 | 399208m2 | |

| Zigzag Pavers 225×112.5×60mm 40pcs/m2 | 30 | 5400 | 43200 | 328101m2 | |

| Perforated Bricks 240x115x90 4 02pcs/m3 | 30 | 5400 | 43200 | 12.96 million pcs | |

| Solid Bricks 240x115x53 683pcs/m3 | 60 | 10800 | 86400 | 25.92 million pcs |

| Dimension | 7200×5200×2900(mm) |

| Size of Pallet | 1350×900×30(Bamboo Plywood) |

| Weight | 13100kg |

| Vibration Frequency | 50-90Hz |

| Maximum Excitation Force | 130KN |

| Molding Cycle | 15-20S |

| Installed Capacity | 45KW |