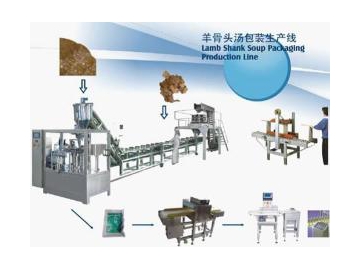

Ice Weighing and Packing System

Ice is wet, breakable, easy to thaw, of high sanitary requirement (food grade) and prone to stick to each other. As a result, it is not easy to pack ice with conventional packing machines. Given this, we have successfully developed an ice weighing and packing system which has 2 or 4 heads to offer reliable ice packing solutions.

Feature

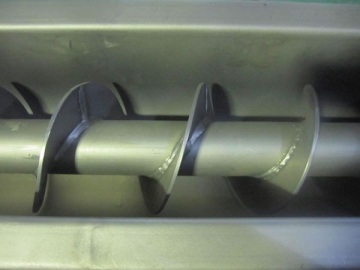

1. Our ice packing machine is specifically designed to vibrate ice when working. So, ice won't stick to each other.

2. Thanks to the circular arc structure, tube ice is able to drop smoothly without the danger of breaking into pieces, and this problem is commonly seen when using conventional ice packing system with quadrate structure.

3. For this ice weighing and packing system, its double-walled frame helps to isolate ice from air during packing, thus protecting ice from thawing.

System Configuration

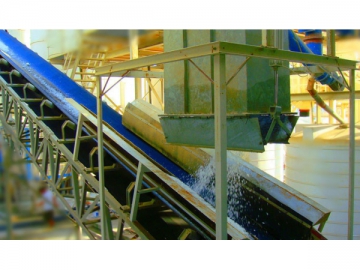

1. Bucket Elevator: Manufactured from 304 stainless steel, the bucket elevator is intended to feed ice into the weighing hopper, and its lifting capacity is 1-10t/h.

2. Weighing Machine: With a pair of weighing hopper (one is fast-supply weighing hopper and the other is slow-supply weighing hopper), this weighing machine offers reliable weighing result with exceptionally high accuracy, and all parts that will come into contact with ice are made from 304 stainless steel.

3. Automatic Vertical Packaging Machine: It is responsible for ice filling, bag sealing, bag printing (packing date/time, serial No., etc.), bag cutting and other jobs, and it makes use of some high-end components, such as Siemens PLC, Panasonic servo motor, Eview touch screen, SMC cylinder and air valve.

4. Ice Bag Conveyor: Our ice weighing and packing system uses an ice bag conveyor to transport finished products, and this conveyor is so clean that ice bags won't get contaminated.

5. Platform: This ice handling equipment can be outfitted with either a carbon steel platform or a stainless steel platform as per customer's needs.

| Model | ||

| Head quantity | 2 | 4 |

| Weighing range | 200g-5kg | 200g-6kg |

| Weighing accuracy | ±3g(200g), ±10g(5kg) | ±3g(200g), ±10g(6kg) |

| Packing speed | 10-12 bags/min (for 2kg-6kg) | 10-12 bags/min (for 2kg-6kg) |

| Bag type | Pillow bag | |

| Bag size (L×W) | (50-460)×(80-350)mm | |

| Power | 380V/6kW | |

| Compressed air requirement | 0.6MPa, 0.36m3/min | |

| Machine weight | 1300kg | |

| Machine size | 3500×2005×5400mm | |

| Min. hole diameter of reel | Ф75mm | |

| Max. O.D. of reel | Ф500mm | |

Note: Standard bag film is laminated film, and the sealing temperature is regulated by a temperature controller. If PE film is preferred, we will adopt heater strip to give instant heating for the purpose of sealing.