Tandem Press Brake

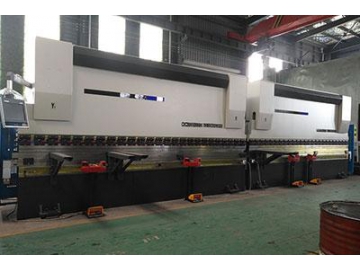

This 2-WF67K tandem press brake stands out for its high working efficiency processing precision. Designed and manufactured with advanced technologies, it is known a reliable metal plate bending machine and could be used to bend plates into various shapes with the help of moulds. Nominal pressure of this series press brake is from 2×1000KN to 2×16000KN, and this brake press has been applied for manufacturing industry such as lighting poles, pipes, autos and ships, decorations.

Components of Tandem Press Brake

1. This CNC electro-hydraulic servo press brake is a tandem press brake consisting of two units of press brake.

2. Each bending machine contains such import components as rack, upper sliding stroke, operation table, right and left cylinders, oil pump motors, hydraulic valves, CNC system, gratings, electrical system, deflection compensation device, front and rear pusher devices and upper and lower dies.

3. There are two cylinders which are respectively mounted at the upper right and upper left of the rack and connected by fastening pieces. The sliding stroke of this tandem bending machine for metal plate, connected with the right and left cylinders, move along the guide rail on the rack. The vertical plate is mounted under the rack and the deflection compensation device on the worktable.

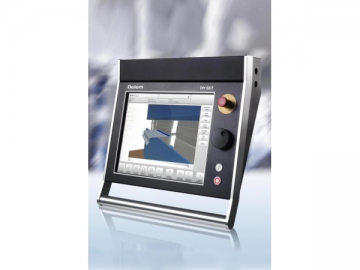

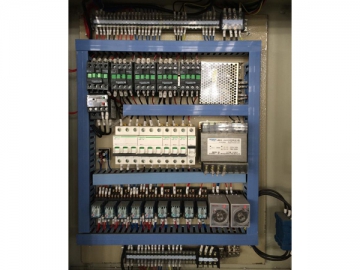

4. The CNC system provided by Delem and the electrical cabinet are mounted at each side of the two press brakes, the servo-proportional valves on the top part of the cylinders, and the pressure valves and oil pump motors on the oil tank.

5. The front and rear pusher devices of this sheet metal fabrication equipment are mounted on the front and rear parts of this Tandem press brake.

Features of Tandem Press Brake

1.Servo valves provided by Rexroth(Germany) and gratings provided by Heidenhain(Germany)form a closed control loop which is very synchronization system for the main cylinders. This synchronization system could precisely control the moving of sliding stroke and ensure high precision of bending operation.

2. Rack of this electro-hydraulic bending machine adopts a welded steel structure that has gone through strict tempering treatment and vibration stress relief treatment. This subtle design could significantly avoid the deformation caused by welding stress and processing stress, ensuring the high precision of the machine tool.

3. The split structure of this sheet metal brake makes the machine too easier to process and transport. More importantly, this structure design could ensure the high precision of the entire machine.

4. The machine body, sliding stokes, cylinders and other important parts have been analyzed by ANSYS to ensure the machine tool to enjoy highly reliable performance.

5. The hydraulic system of this metalworking machinery adopts integrated control system made in Germany, requiring less pipes and promoting the machine tool’s reliability.

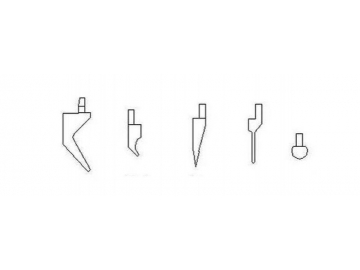

6. There are also sectional upper clamp dies provided to customers, which could be assembled according to their needs for the length of the die in different application. At the mean time, the upper die of the clamp adopts a security trench structure and the lower die adopts a concentric structure that enjoys high precision. Therefore, the dies are quite easy to remove and install.

7. The CNC system of this torsion bar synchrony press bar synchrony press is provided by DELEM in Netherlands.

8. At both sides of the machine body mounted two C-shape boards where the gratings are mounted. This unique design could help avoid negative influences on the bending operation imposed by the deformation of the machine.

9. The quality cylinder, imported seal rings and pipe joints of this sheet metal bending brake could effectively avoid oil leakage.

Front and Rear Pusher Devices

There are two sorts of pusher devices available for customers

1.Electrical push button type: this type of pusher device requires users to put plates on the front pusher and then press the button. If the size of the plate to be bent larger than the allowable dimension, press the button of “rear pusher” and then it would be conveyed the right position to be bent.

2. CNC type: both the front and rear pusher devices of this tandem press brake are controlled by the CNC system. The pushing system consists of four axes, namely the X1, X2, X3 and X4. This type of pushing system allows users to write a program for pushing processes and enables the sheet metal brake to bend plates in one step.

CNC System of Tandem Press Brake

For detailed information about this system, please click "CNC System"

Configuration of Tandem Press Brake

1. Hydraulic system provided by Atos(Italy);

2. Electrical system provided by Schneider(France)

3. Gear pump provided by Chengjie (devices provided by other foreign suppliers are also available for users, such as that provided by Sumitomo);

4. Main motor provided by Shuangta(China)( devices provided by other foreign suppliers are also available for users, such as that provided by Siemens);

5. E210 system provided by Estum(China)( devices provided by other foreign suppliers are also available for users, such as the DA41 system provided by DELEM)

6. Ball screw provided by Taiwan supplier.

| Model | PN | Length of Table | Column Distance | Throat Depth | Stroke Length | Maximum Open Height | Main Motor Power | Dimensions |

| (KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (kW) | L×W×H(mm) | |

| 2×1000 | 2×3200 | 2800 | 320 | 150 | 460 | 2×11 | (2×3200)×1400 ×2400 | |

| 2×1600 | 2×3200 | 2700 | 400 | 200 | 500 | 2×15 | (2×3200)×1650 ×2700 | |

| 2×1600 | 2×4000 | 3400 | 400 | 200 | 500 | 2×15 | (2×4000)×1650 ×2800 | |

| 2×2000 | 2×3200 | 2700 | 400 | 200 | 500 | 2×18.5 | (2×3200)×1700 ×2750 | |

| 2×2000 | 2×4000 | 3400 | 400 | 200 | 500 | 2×18.5 | (2×4000)×1700 ×2850 | |

| 2×2500 | 2×3200 | 2700 | 400 | 200 | 500 | 2×18.5 | (2×3200)×1750 ×2750 | |

| 2×2500 | 2×4000 | 3400 | 400 | 200 | 500 | 2×18.5 | (2×4000)×1750 ×2850 | |

| 2×3000 | 2×3200 | 2700 | 400 | 200 | 500 | 2×22 | (2×3200)×1800 ×2800 | |

| 2×3000 | 2×4000 | 3400 | 400 | 200 | 500 | 2×22 | (2×4000)×1800 ×2900 | |

| 2×4000 | 2×4000 | 3400 | 400 | 250 | 580 | 2×30 | (2×4000)×2100 ×3100 | |

| 2×4000 | 2×5000 | 4200 | 400 | 250 | 580 | 2×30 | (2×5000)×2100 ×3300 | |

| 2×4000 | 2×6000 | 5200 | 400 | 250 | 580 | 2×30 | (2×6000)×2200 ×3800 | |

| 2×5000 | 2×4000 | 3300 | 500 | 320 | 590 | 2×37 | (2×4000)×2600 ×4400 | |

| 2×5000 | 2×5000 | 4200 | 500 | 320 | 590 | 2×37 | (2×5000)×2600 ×4600 | |

| 2×5000 | 2×6000 | 5200 | 500 | 320 | 590 | 2×37 | (2×6000)×2600 ×4800 | |

| 2×6000 | 2×6000 | 5000 | 500 | 320 | 640 | 2×45 | (2×6000)×2650 ×5200 | |

| 2×6000 | 2×7000 | 6000 | 500 | 320 | 640 | 2×45 | (2×7000)×2650 ×5500 | |

| 2×6000 | 2×8000 | 7000 | 500 | 320 | 640 | 2×45 | (2×8000)×2750 ×5700 | |

| 2×8000 | 2×6000 | 5000 | 600 | 420 | 820 | 2×55 | (2×6000)×2650 ×5500 | |

| 2×8000 | 2×7000 | 6000 | 600 | 420 | 820 | 2×55 | (2×7000)×2650 ×5700 | |

| 2×10000 | 2×8000 | 7000 | 600 | 420 | 820 | 2×55 | (2×8000)×2750 ×5900 | |

| 2×10000 | 2×6000 | 5000 | 600 | 420 | 1000 | 2×55 | (2×6000)×3050 ×5700 | |

| 2×10000 | 2×7000 | 6000 | 600 | 420 | 1000 | 2×55 | (2×7000)×3150 ×6000 | |

| 2×10000 | 2×8000 | 7000 | 600 | 420 | 1000 | 2×55 | (2×8000)×3150 ×6500 | |

| 2×12000 | 2×6000 | 5000 | 600 | 420 | 1000 | 2×75 | (2×6000)×3100 ×5900 | |

| 2×12000 | 2×7000 | 6000 | 600 | 420 | 1000 | 2×75 | (2×7000)×3250 ×6500 | |

| 2×12000 | 2×8000 | 7000 | 600 | 420 | 1000 | 2×75 | (2×8000)×3250 ×7000 | |

| 2×16000 | 2×6000 | 5000 | 600 | 420 | 1000 | 2×110 | (2×6000)×3200 ×6200 | |

| 2×16000 | 2×7000 | 6000 | 600 | 420 | 1000 | 2×110 | (2×7000)×3350 ×6700 | |

| 2×16000 | 2×8000 | 7000 | 600 | 420 | 1000 | 2×110 | (2×8000)×3350 ×7200 |