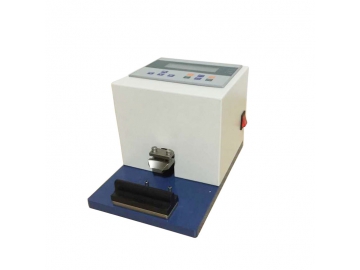

Compression and Deformation Tester

The compression and deformation tester is used to test the restorability of the rubber under static compression.

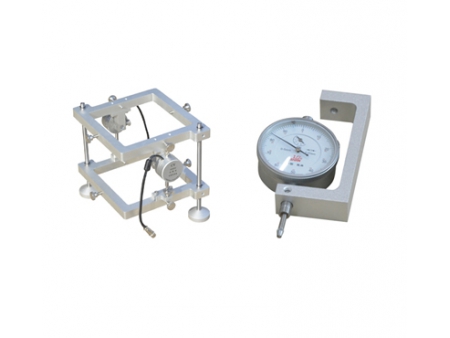

The test piece is clamped between the plates of the rubber product testing equipment. The compression and deformation tester is designed with tightening screws for compression. Afterwards, the test piece shall be put in the oven with specific temperature. Generally, the heating time shall be 22 hours and 70 hours at the temperature of 70°C and 100°C, respectively. After that, users shall take the test piece out of the oven, cool it for 30 minutes, and calculate the compression deflection rate with the following formula.

(Rubber thickness before compression)- (Rubber thickness after compression)÷(Rubber thickness before compression-spacing board thickness)×100

Technical Parameters of Compression and Deformation Tester

| Model | |

| Test piece size | Rubber: 28.68×12.7mm (Dia.×height) Foamed plastic: 50×50×25mm (L×W×H) |

| Spacers | 5mm: 3, 12.5mm: 3, 25mm: 3 |

| Dimension (L×W×H) | 20×12×10cm |

| Weight | 12 kg |

| Standards | CNS 3560, CNS 10487, JIS-K6301, ASTM D395, GB 7759 |

| Test Piece Hardness | Compression Rate | Thickness of Pressing Plate | |

| ASTM | JIS | ||

| Below 45 | Below 40 | 40% | 7.62mm |

| 45-65 | 41-60 | 30% | 8.89mm |

| 65-85 | 61-80 | 25% | 9.52mm |

| Above 85 | Above 81 | 20% | 10.16mm |

Related Names

Deflection Compression Testing Machine︱Laboratory Testing Equipment