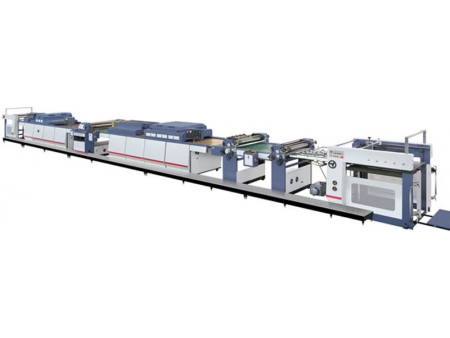

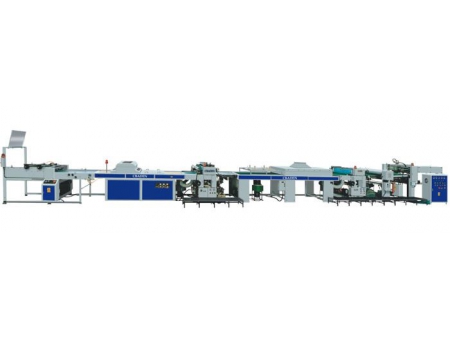

Automatic UV Coating Machine (For Coating Paper)

Performance and Features

Our SGJ-UV automatic UV coating machine is suitable for the full-scale and partial UV coating of rubber blanket or flexographic plate material. This automatic coating equipment is capable of achieving accurate register and uniform coating partially and effectively improving the quality of printed materials. Moreover, our automatic UV coating machine can increase the sense of beauty and enhance the waterproof property and wear resistance.

Our automatic UV coater has humanized operating program and adequate installations of protective devices, which can not only offer easy and flexible operation to operators, but also ensure their safety. Additionally, the imported main bearings and electrical components of our automatic UV coating machine can ensure the product performance.

Parameters of Automatic UV Coating Machine| Models | ||

| Maximum paper size | 850mm×1,100mm | 850mm×1,285mm |

| Maximum UV Coating area | 760mm×1,060mm | 800mm×1,260mm |

| Minimum paper size | 310mm×400mm | 310mm×400mm |

| Maximum coating speed | 5,000 Pieces/ Hour | 5,000 Pieces/ Hour |

| Total power | 45kw | 45kw |

| Number ×UV lamp | 3×9.75kw | 3×9.75kw |

| Number ×IR drying (optional) | 15×1.5kw | 15×2kw |

| Paper weight | 80g/m2 - 450 g/m2 | 80g/m2 - 450 g/m2 |

| Weight | 6.6t | 7.5t |

| Dimension | 7,600mm×2,600mm×1,950mm | 7,600mm×2,900mm×1,950mm |

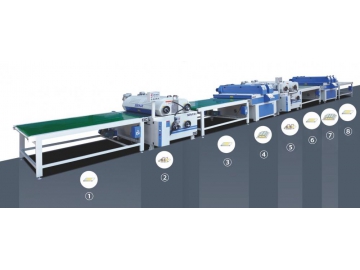

Details of Automatic UV Coating Machine

1. Paper feed unit

The paper feed unit has high-speed multi-point feed head, which generates easy operation and convenient adjustment. It does not require lubrication and has good wear resistance. Our automatic UV coating machine's paper feed unit can simply have centralized adjustment.

The front register and the side register both have mechanically photoelectrical control to ensure the accurate paper positioning. The pneumatic paper pressing mechanism will automatically work and the paper feed unit will stop so as to protect the printing plate and avoid the wasted paper products.

*The non-stop pre-stack paper feed system is optional to improve work efficiency.

2. UV coating mechanism

The UV coating mechanism has gripper type chain conveyor system. The impression roller and the plate roller are pressed and released pneumatically and automatically. The UV ink supply device has reversible rollers and can generate more uniform coating.

Our automatic UV coating machine's UV ink tank is indirectly heated by the automatic temperature control, which can maintain the UV ink's leveling property under any temperatures.

*The chambered doctor blade coating system with ceramic anilox roller is optional.

3. IR drying tunnel

Our UV coating machine for sale has IR drying tunnel used for the drying of paper products with water-based coating. (Optional)

4. UV curing system

The UV drying system consists of high-pressure mercury lamp, mirror reflective plates, electrical control, cooling device and exhaust system. The automatic temperature control system can prevent the deformation of the coated material.

Our automatic UV coating machine has full power/half-power mercury lamps, namely, the full power mercury lamps will work in the normal operation; the half-power mercury lamps will work and save power when the machine is short of paper.

5. Paper collecting unit

The design of turn-up type security door greatly facilitates the operation; the speed regulating suction roll mechanism can assist the collection; the fan-cooled structure can ensure the orderly collection of large-sized paper.

*The air cooling system is optional to guarantee quality coating.