TPM2020 / TPM2525 / TPM3030 CNC Steel Plate Drilling Machine

Application

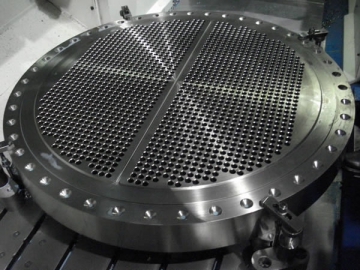

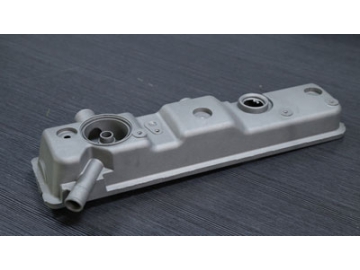

Our CNC steel plate drilling machine can be excellently used to drill holes on tube, baffle and flange plates in petrochemical, boiler, refrigeration, and wind power industries. This CNC drilling equipment can also drill junction plates for steel structures in construction, bridge and tower building.

Features

1. The CNC steel plate drilling machine is equipped heavy-load linear rolling guide pairs on both sides of its body. The longitudinal movement of the gantry (X axis) is driven by a synchronous belt that is connected with the AC servo motor and precise ball screw pair with a coarse pitch.

2. We have installed two movable sliding plates on the cross beam of our CNC drilling machine’s gantry. The sliding plates are guided by two linear rolling guide pairs and driven by the AC servo motor and precise ball screw pair with coarse pitch.

3. Our CNC steel plate drilling machine has a hydraulic system that can achieve hydraulic balancing of the vertical ram and loosen the cutter.

4. The drilling spindle is a precision inner-cooled spindle from Taiwan, and has a Bellville spring, and a automatic broach mechanism. It also has a hydraulic cylinder to loosen the cutter, making it easy to change the tool holder.

5. Our CNC high speed drilling machine has a hydraulic system that can achieve hydraulic balancing of the vertical ram and loosen the cutter.

6. We use the FAGOR8055 CNC system from Spain, and an RS232 interface and LCD screen on our CNC drilling press. The provided automatic programming of our CNC high speed drilling machine can not only generate processing programs automatically, but it can also preview the hole location before drilling.

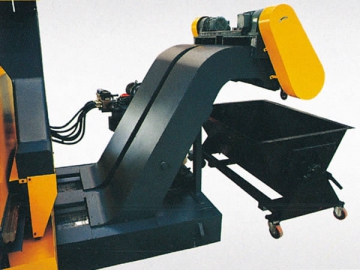

7. There are chain-plate automatic chip cleaner and chip collectors in our CNC high speed drilling machines. The cooling system is equipped with a filter, a high pressure inner cooling pump and low-pressure external cooling pump, which are used for inner or external cooling.

Parameters| Model | ||||

| Max. size of workpiece(mm) | Max. center distance L×W(mm) | 2,000×2,000 | 2,500×2,500 | 3,000×3,000 |

| Max. thickness of workpiece (mm) | 250 | |||

| Worktable | Width/distance of T groove(mm) | 28/500 | ||

| Drilling spindle | Quantity | 1 or more | ||

| Spindle taper | BT50 | |||

| Max. drilling diameter (mm) | Φ40 (carbide drill)Φ50(HSS twist drill) | |||

| Rotation speed (stepless)(r/min) | From 30 to 2800 | |||

| Motor power of spindles(kw) | 22/33kw | |||

| Distance from the spindle's bottom end face to the worktable's surface (mm) | From 300 to 800 | |||

| Longitudinal movement of gantry (X axis) | Max. stroke (mm) | 2,000 | 2,500 | 3,000 |

| Feeding speed on X axis(m/min) | From 0 to 8 | |||

| Servo motor power on X axis(kw)/ torque(nm) | 2×3/28.4 | |||

| Horizontal movement of gantry (Yaxis) | Max. distance between two spindles (mm) | 2,000 | 2,500 | 300 |

| Feeding speed on Y axis(m/min) | From 0 to 8 | |||

| Servo motor power on Y axis(kw) | 3 | |||

| Vertical movement of gantry (Zaxis) | Max. stroke on Z axis (mm) | 500 | ||

| Feeding speed on Z axis(m/min) | 0-5 | |||

| Servo motor power on Z axis(kw)/ torque(nm) | 3/28.4 | |||

| Positioning precision | X axis and Y axis | ≤0.1/ (full length) | ||

| Re-positioning precision | X axis and Y axis | ≤0.05 | ||

| Hydraulic system | Hydraulic pump pressure (Mpa)/ flow (L/min) | 6.5 /25 | ||

| Hydraulic pump motor power(kw) | 3 | |||

| Chip removal and cooling | Type of chip collector | Chain-plate type | ||

| Quantity of chip collector | 2 | |||

| Chip removal speed (m/min) | 1 | |||

| Motor power for chip collector (kw) | 0.75 | |||

| Motor power for inner cooling water pump (kw) | 3 | |||

| Motor power for external cooling water pump(kw) | 0.75 | |||

| Auto lubrication system | Lubrication pressure (MPa) | 2 | ||

| Injection flow (ml) | 0.1 | |||

| Lubrication cycle(min) | 6-10 | |||

| Dimension (L×W×H) (m) | Appr.5.2×5.1×3.6 | Appr.5.7×5.6×3.6 | Appr.6.2×6.1×3.6 | |

| Weight (t) | Appr. 30 | Appr. 35 | Appr. 40 | |