TPPR103 / TPPR104 CNC Hydraulic Punching Machine

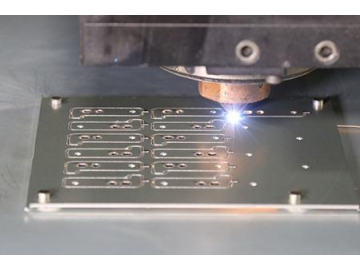

Our CNC hydraulic punching machine is primarily used for punching and marking the junction plates in tower and sheet metal processing industries. The machine body is comprised of C-shaped welded steel plates, all of which feature excellent rigidity and a wider working space.

Operation of the X and Y axes are driven by the servo motor and ball screw, and this dual axis CNC system controls the positioning for punching. Operating staff has only to enter work piece dimensions, and the CNC processing equipment will work automatically from there. The CNC machine can also store that data for repeated use in the future.

Our CNC hydraulic punching machine also has three dye stations, one of which is used for marking, and all three can have an automatic switchover from manual to automatic or vice versa. The gripper system can also adapt to work pieces with different thicknesses. The equipment also has a standard zero position stop plate, and the ball screw workbench that can support the work piece.

Features

1. We utilize advanced CNC technology and a servo motor controlled feeding system to enable our plate processing equipment with better efficiency and generate work pieces that are more accurate.

2. With each of its main parts put together in a modular assembly, our CNC marking machine requires little to no maintenance.

3. With a strengthened machine body and an enlarged oil cylinder, our CNC hydraulic punching machine has a punching force that is more stable, which makes it suited for processing steel plates with a higher strength.

4. Its programming is simple. Just enter the bore diameter, position and quantity of the work piece. The program generated from the sample software can also be used.

5. Built with a servo motor, ball screw and linear guideway, the X and Y axis both have better precision.

6. Our CNC equipment comes equipped with a self-diagnosing technology that automatically searches for faults.

7. The workbench is equipped with a stainless steel plate, which has a better appearance and more practical.

Parameters of CNC Hydraulic Punching Machine| Model | ||

| Max. dimension of workpiece (L×W) (mm) | 1,500×800 | 1,500×1,000 |

| Max. punching diameter (mm) | Φ26 | |

| Thickness of punched-plate (mm) | From 5 to 25(Q235) | From 5 to 25(Q345, 16Mn) From 5 to 20(Q420) |

| Punching force (kn) | 1,000 | 1,200 |

| Marking force (kn) | 800 | 1,000 |

| Min. distance between hole and plate's edge (mm) | 25 | |

| Dimension of character (mm) | 14×10×19 | 14×10×19 / 20×12×19 |

| Number of character | 12 | 16 / 14 |

| Number of die station | 3 | |

| Processing precision | In accordance with GB2694 | |

| Programming mode | Keyboard input, RS232 interface, floppy disk and USB interface | |

| Dimension (L×W×H) (mm) | 3,400×3,200×1,900 | 3,500×3,000×1,900 |

| Weight (kg) | Appr. 6,500 | Appr. 6,900 |