Grinding Balls

The grinding balls supplied by HUAZHENG are in strict conformity with the standards of GB8649-1988 for rolled steel balls and the standards of YB/T091-2005 for forged or rolled steel balls. The grinding media are rolled from high carbon alloy steels. The diameter of this steel ball ranges from ø20mm to ø125mm. It comes with 14 kinds of specifications.

As a Chinese leading manufacturer of hot rolled steel grinding media, HUAZHENG can freely offer the optimal proportion of grinding balls and relevant technical supports as well as the superior solutions with high cost performance according to the requirements of various customers for grinding media balls and some actual conditions such as hardness of minerals to be ground, size of grinding mill, etc.

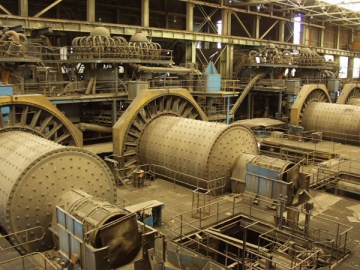

In virtue of incomparable performance, our grinding steel balls have been widely used in ball mills for fine grinding and pulverizing crushed minerals and other things in various industries such as nonferrous metal mineral separation industry, thermal power generation industry, cement and building materials industry and non metal crushing industry etc.

Characteristics of Grinding Balls

1. High Global Hardness

Surface hardness can reach 59-64HRC and volume hardness is up to 58-64HRC. In addition, the hardness comes with a uniform gradient distribution.

2. High Impact Toughness

The milling media features a high impact toughness that is more than 12J/cm2.

3. Low Breakage Rate

Our grinding media balls boast superior crush resistance which is over 10 times as many as general forged steel grinding balls. The falling ball impact can last more than 20,000 times. Due to that, the actual breakage rate is just 1% or less, close to zero breakage.

4. Uniform Microstructure

The center and surface microstructure of our grinding balls is uniform, ensuring outstanding wear and impact resistance.

Technical Parameters of Grinding Balls

| Diameter (mm) (ins) | Surface Hardness (HRC) | Core Hardness (HRC) | Volumetric Hardness (HRC) | Impact Toughness (J/CM²) | Material | |

| 20 | 3/4 | 62~64 | 62~64 | 62~64 | — | B2 |

| 25 | 1 | 62~64 | 62~64 | 62~64 | — | B2 |

| 30 | 1 1/4 | 62~64 | 62~64 | 62~64 | — | B2 |

| 40 | 1 1/2 | 61~63 | 61~63 | 61~63 | — | B2 |

| 50 | 2 | 61~63 | 61~63 | 61~63 | 7-15 | B2 |

| 60 | 2 1/2 | 61~63 | 61~63 | 61~63 | 7-15 | B2 |

| 70 | 2 3/4 | 60~63 | 60~63 | 60~63 | 7-15 | B2 |

| 80 | 3 1/4 | 60~63 | 59~62 | 59~61 | 12-25 | B3 |

| 90 | 3 3/4 | 60~63 | 59~62 | 59~61 | 12-25 | B3 |

| 100 | 4 | 60~63 | 59~62 | 59~61 | 12-25 | B3 |

| 110 | 4 1/2 | 59~62 | 55~58 | 58~60 | >20 | B3 |

| 125 | 5 | 59~62 | 55~58 | 58~60 | >20 | B5 |

Production and Packaging

Difference between Hot Rolled Steel Ball and Forged Steel Ball

Firstly, the materials used for making hot rolling steel balls and forged steel balls are quite different. The former is made of high carbon alloy steels and manufactured from finished round steel produced by normal special steel plants. Meanwhile, the round steels should be hot rolled from square steel billets that are over 10 times larger than them. The latter is mainly made from collected steel scraps with an addition of a certain proportion of alloy elements.

The differences in materials of hot rolled steel grinding balls and forged steel balls lead to differences in performance. The performance differences are embodied in four aspects.

1. Different Hardness Formation Principle

During the manufacturing process of hot rolled steel balls, quenching process is employed to achieve super quick cooling, turning original austenitic structure of steel into martensitic structure which boasts considerable abrasion hardness. Therefore, the hardness of this type of grinding ball is formed by means of quenching process.

Diversely, the forged steel balls come with relatively low harness and wear resistance that are generated by adding a certain amount of Cr. The higher the content of Cr is, the higher the hardness and wear resistance are. However, such steel balls are so expensive. For example, the forged steel ball in the market with high Cr content up to 18%, high hardness of 60~62HRC and great wear resistance is worth at least 14,000 RMB.

2. Different Densities

The hot rolled steel grinding balls are made from round steels that are rolled from square steel billets. During production process, the rollers are used for forming the balls. Consequently, the density of hot rolled balls is generally more than 7.85.

The forged steel grinding media balls are made by conventional sand casting process, thus inevitably generating pore and sand inclusion in ball interior and on ball surface, or causing slitter edge. As a result, the density of forged steel balls is about 7.45.

3. Different Quality Uniformity

Since the hot rolled steel balls are all manufactured from finished round steels, they boast unified quality. And the whole production process of the grinding media has achieved mechanization and assembly line work from heating furnace, rolling mill, quenching machine, tempering furnace, cooling table to packaging. In addition, technological parameters such as temperature, speed, etc. are controlled by computer, thus ensuring stable and uniform quality.

The forged balls, however, employ steel scraps which are non uniform in textures. Plus, burdening ratio and casting speed of each furnace is heavily influenced by human factors. Therefore, finished product quality is hard to be controlled.

4. Different Impact Toughness and Breakage Resistance

Due to high density, high impact toughness of 12J/cm2 or more and long fatigue life that is up to 10,000 times or more in 6m falling ball test, the hot rolled steel grinding balls come with ultra low breakage rate.

Since the forged steel balls have pore and sand inclusion in ball interior and on ball surface, their impact toughness is generally 4 J/cm2 or less. They are not competent for falling ball test. Hence, their breakage rate is high.

In a word, the hot rolled steel balls and forged steel balls are pretty different. The former is not only superior in performance but also environment friendly and energy saving. Finally, they will replace the traditional forged steel grinding balls.