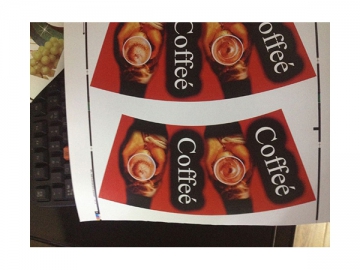

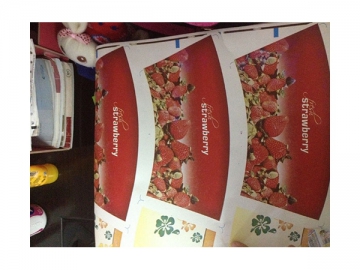

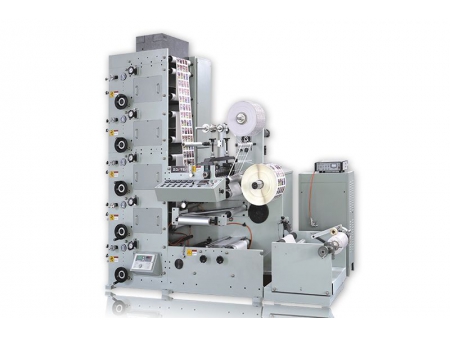

Flexo Printing Machine (Paper Cup Printing)

Our cost-effective flexo printing machine is designed to print on paper cups, commercials bills, self-adhesive labels, and a variety of other applications.

Features

1. Our paper cup printing machine uses a ceramic anilox roller to transfer ink, the surface of which is covered with tiny cells of the same shape. These cells give the roller a smooth inner surface for neatly transferring ink and easy cleaning.

2. A magnetic powder brake and clutch keeps the unwinding and rewinding of the material being printed upon precisely controlled. Mitsubishi automatic tension controllers are optional.

3. The imported motor of this flexo printing machine has a variable frequency stepless speed regulation, while each printing station, fitted with an IR dryer, uses a 360 degree running lineal registration.

4. When the print job has stopped or finished, the anilox roller stops contacting the plate cylinder and continues rotating at a low speed to avoid ink drying.

5. This automatic flexographic printing press can finish the entire production process in one run, including paper feeding, web correction, printing, varnishing, automatic IR drying, film coating, rotary die cutting, waste matrix stripping, slitting, and rewinding.

Advantage:

1. The flexo printing machine is equipped with seperated rewinding and unwinding system, ensuring easier operation.

2. Normally 20mm thick machine plate is offered in the market, but the thickness of our machine plate can reach 26 mm.

3. Although the cost of our gear box is a little higher than others, it has a higher precision.

4. We not only increase the thickness and width of the machine, but also increase the cylinder diameter, especially for the anilox roller, whose cylinder diameter can be 84.88mm. But generally, small cylinder is equipped in the printing machine.

5. The unwinding and rewinding tension controller from Mitsubishi is available.

6. The machine include the hydraulic unwinding/rewinding loader, so the diameter of unwinding and rewinding can be 1400mm.

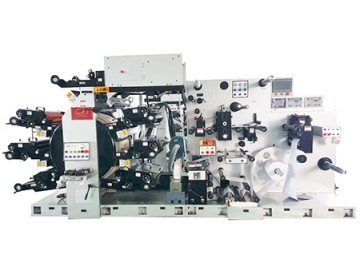

RY650

Standard Configuration

1. A simple plate mounting machine

2. An anilox roller for each printing station

3. Three printing rollers for each printing station

4. Unwinding tension controller (Mitsubishi, Japan)

5. Rewinding tension controller

| Printing speed | 60m/min |

| Max. web width | 650mm |

| Max. printing width | 630mm |

| Max. unwinding diameter | 1100mm |

| Max. rewinding diameter | 1000mm |

| Printing girth | 175-380mm or 250-580mm |

| Precision of registration | ±0.15mm |

| External dimension | 2500L *1450W*3000H(mm) |

| Total weight | About 3500kg |

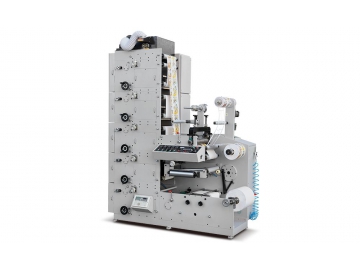

RY850

Standard Configuration

1. A simple plate mounting machine

2. An anilox roller for each printing station

3. Three printing rollers for each printing station

4. Unwinding tension controller (Mitsubishi, Japan)

5. Rewinding tension controller

| Model | RY850 |

| Printing speed | 50m /min |

| Max. web width | 860mm |

| Max. printing width | 850mm |

| Max. unwinding diameter | 800mm |

| Max. rewinding diameter | 600mm |

| Printing girth | 250-580mm |

| Precision of registration | ±0.2mm |

| External dimension | 2500L *1450W*3300H(mm) |

| Total weight | About 4500kg |

RY950

Standard Configuration

1. A simple plate mounting machine

2. An anilox roller for each printing station

3. Three printing rollers for each printing station

4. Unwinding tension controller (Mitsubishi, Japan)

5. Rewinding tension controller

| Model | RY950 |

| Printing speed | 50m/min |

| Max. web width | 960mm |

| Max. printing width | 950mm |

| Max. unwinding diameter | 800mm |

| Max. rewinding diameter | 600mm |

| Printing girth | 250-580mm |

| Precision of registration | ±0.2mm |

| External dimension | 2500L*1450W*3300H(mm) |

| Total weight | About 4500kg |

Lead time: 60 days

Terms of payment: 30% of deposit after signing the contract, 70% of balance payment before delivery

Installation and commissioning

When the flexo printing machine reaches the buyer’s plant, the seller sends technical personnel to do the installation and commissioning, and also will train the buyer how to operate the machine. The machine has a one year warranty period. During this period, the parts damage caused by the quality problems, the seller will provide parts free of charge, but the buyer should be responsible for shipping cost. If the parts damage caused by improper operation, the seller is willing to provide replacement parts with charge fees.

Related Names

Label Printing Machine | Paper Label Flexo Printing Machine | Label Flexo Printing Machine