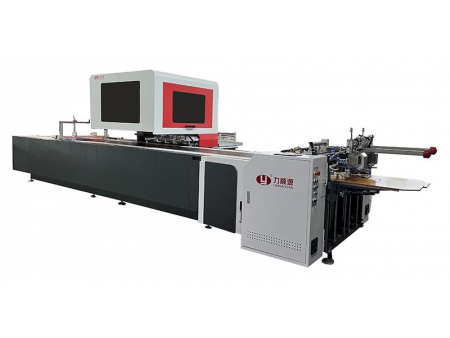

Multifunctional Visual Positioning Machine, LY-485C

Suitable for use in rigid box and hardcover production line

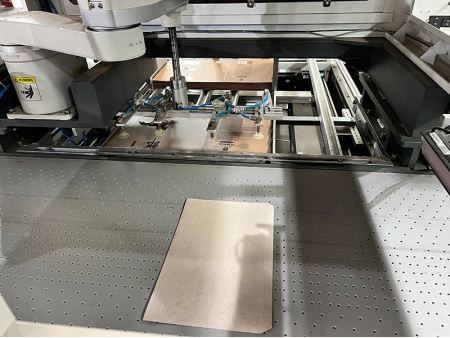

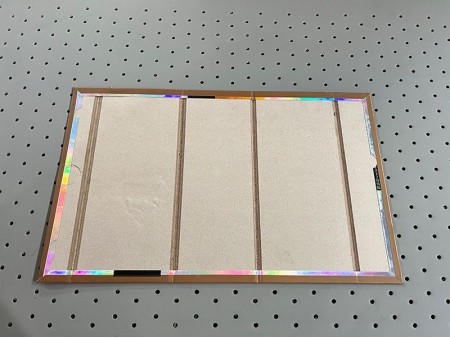

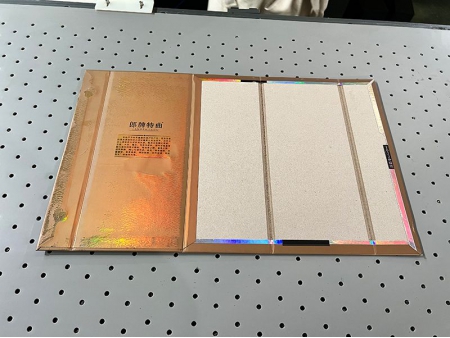

The LY-485C multifunctional visual positioning machine is equipped with advanced features that offer precise positioning for a variety of high-end boxes. The positioning machine’s feeder, gluer, and belt conveyor are separately servo controlled, ensuring smooth performance. Moreover, it comes with a YAMAHA robotic arm and a camera imaging system for accurate positioning, making it perfect for gluing products such as phone boxes, cosmetic boxes, jewelry boxes, watch boxes, wine boxes, cigarette boxes and etc.

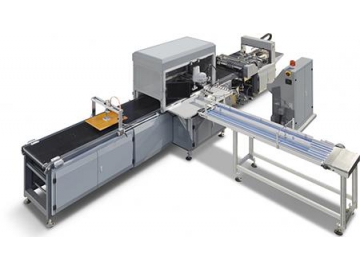

The LY-485C multifunctional visual positioning machine has great scalability for future products, as it can be paired with corner pasting machines, cardboard splicer machines, case wrapping machines to create a range of two-piece boxes and cases.

Features

- The multifunctional visual positioning machine has top cardboard manufacturing and pasting speed of 20-30 pieces per minute.

- The visual positioning machine is equipped with separate HMI, allowing for quick mode switching and setting.

- The rigid box positioning machine has the functions of troubleshooting and 24-hour-controlled glue pre-heating.

- The host module has adjustable box positioning, with the accuracy of ±0.05 mm and the top speed of 25-35 pieces per minute.

- The visual positioning machine has great scalability for future products, since it can be configured with corner pasting and wrapping machines.

| Paper Size | W (min) | 95 mm |

| W (max) | 600 mm | |

| L (min) | 180 mm | |

| L (max) | 880 mm | |

| Paper Thickness | 80-300 g/㎡ | |

| One-piece Cardboard Size | L min | 180 mm |

| L max | 820 mm | |

| W min | 95 mm | |

| W max | 400 mm | |

| Minimum Separated Cardboard Size | 50*85 mm | |

| Cardboard Gap | ≥2 mm | |

| Finished Box Size (L*W*H) | min | 600 mm*400 mm*120 mm |

| max | 70 mm*60 mm*15 mm | |

| Manufacturing Speed | 25-35 sheets/min | |

| Positioning Accuracy | ±0.05 mm | |

| Maximum Power | 11.5 kW | |

| Overall Size (L*W*H) | 8000 mm*2550 mm*2000 mm | |

| Weight | 2000 kg | |

-

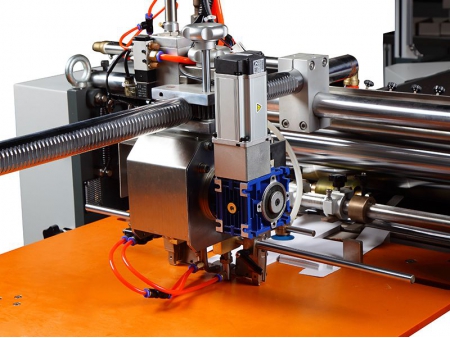

- Full servo controlled dual feeders ensure feeding stability.

- Front-suctioning and rear-blowing feeders avoid double-sheet feeding.

-

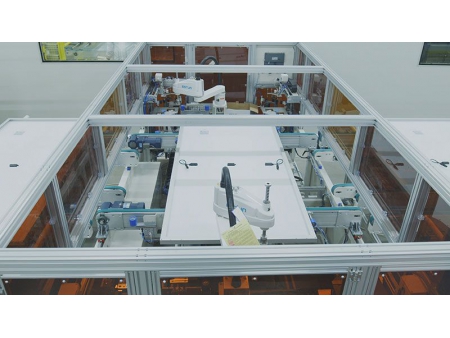

- Dual Germany-made industrial cameras with the resolution of 5 million pixels plus YAMAHA-made robotic arm allow the positioning accuracy reaching ±0.05 mm.

- Available for lining the whole surface or specific spots.

- Unlike traditional lining techniques, the LY-485C visual positioning machine can avoid surface scratching when lining the interior.

There are some box making Equipment that we featured for choose your best