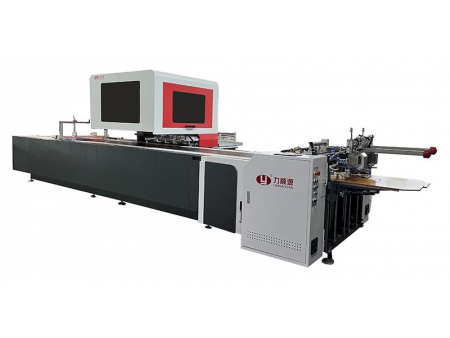

Double Feeding and Visual Positioning Machine, LY-850SD

Request a Quote

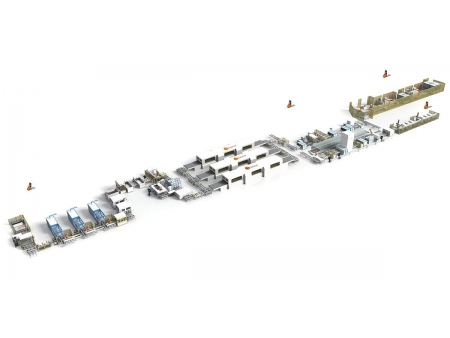

Suitable for use in rigid box and hardcover production line

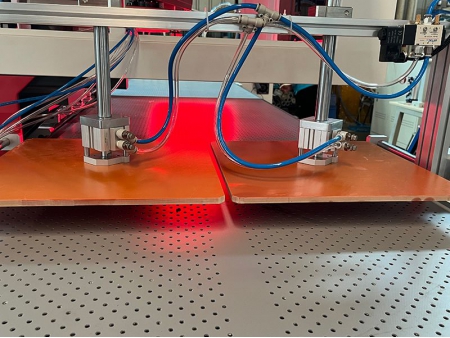

Lishunyuan has developed the LY-850SD visual positioning machine 2 feeders and 4 HD cameras, aiming at satisfying the demand of making both two-piece boxes and hardcovers.

Sample Boxes

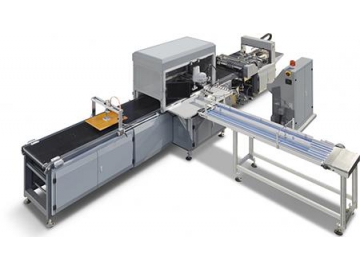

- The paper feeding section features two independent control stations that offer precise step-by-step control for lifting. This allows for handling paper of different thickness.

- The feeder uses servo-driven suction cam, allowing for feeding both thin and thick paper. This feature prevents double-sheet or skewed feeding, making paper feeding more stable and faster.

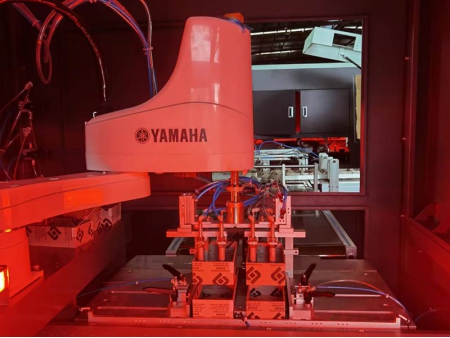

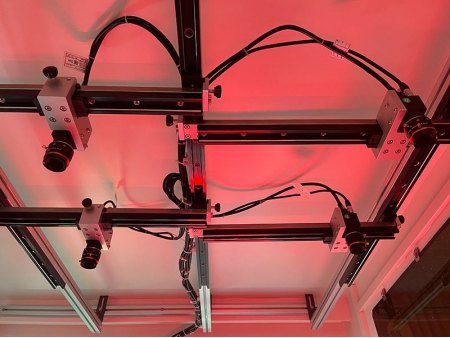

- The visual positioning machine boasts a YAMAHA robotic arm and four HD cameras for image positioning, resulting in more accurate calculations. With a positioning precision of ±0.05mm, this provides superior precision in product manufacturing.

- When processing large sheets of paper, the two pallets can be synchronized to lift and switch between different sizes of paper quickly. Additionally, it can easily switch between single-layer and double-layer printing quickly.

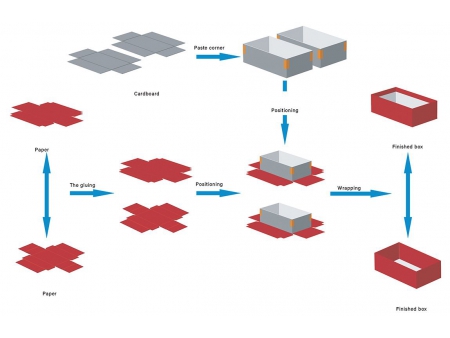

- The visual positioning machine is capable of producing two types of products: two-piece boxes or hardcovers.

- The positioning machine can be switched to single-type product making with one-click, if the other type of products run out.

| Product Model | LY-850SD | |

| Single Sheet Paper Size | W (min) | 45 mm |

| W (max) | 800 mm | |

| L (min) | 120 mm | |

| L (max) | 900 mm | |

| Double Sheet Paper Size | W (min) | 45 mm |

| W (max) | 375 mm | |

| L (min) | 120 mm | |

| L (max) | 900 mm | |

| Paper Thickness | 100-350 g/㎡ | |

| Cardboard Thickness (C*D) | 1-3 mm | |

| Single-Hardcover Cardboard Size | W (min) | 45 mm |

| W (max) | 500 mm | |

| L (min) | 90 mm | |

| L (max) | 1000 mm | |

| Double-Hardcover Cardboard Size | W (min) | 45 mm |

| W (max) | 375 mm | |

| L (min) | 90 mm | |

| L (max) | 375 mm | |

| Minimum Size of Separated Cardboard | Minimum width of 15 mm, paired with the partition with the thickness of 1 mm | |

| Single Box Size | W (min) | 45 mm |

| W (max) | 400 mm | |

| L (min) | 45 mm | |

| L (max) | 700 mm | |

| H (min) | 10 mm | |

| H (max) | 120 mm | |

| Double Box Size | W (min) | 45 mm |

| W (max) | 350 mm | |

| L (min) | 45 mm | |

| L (max) | 450 mm | |

| H (min) | 10 mm | |

| H (max) | 120 mm | |

| Positioning Accuracy | ±0.05 mm | |

| Maximum Power | 12 kW | |

| Manufacturing Speed | 40-50 PCS/MIN | |

| Speed for Single Product | 15-30 PCS/MIN | |

| Speed for Double Product | 32-50 PCS/MIN | |

| Overall Size (L*W*H) | 6100 mm*2900 mm*2000 mm | |

-

- Full servo controlled dual feeders ensure feeding stability

- Double pallets with precise step-by-step control for lifting

- One-click switch to single pallet mode

-

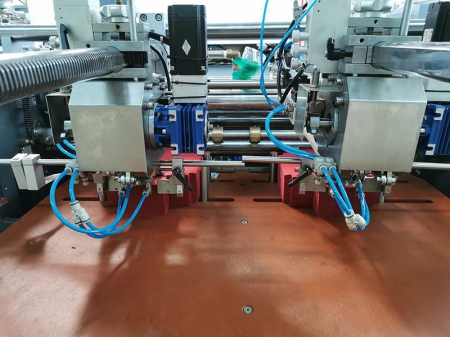

- Type 600 YAMAHA robotic arm with 10kg payload ensures faster and more stable gapping.

-

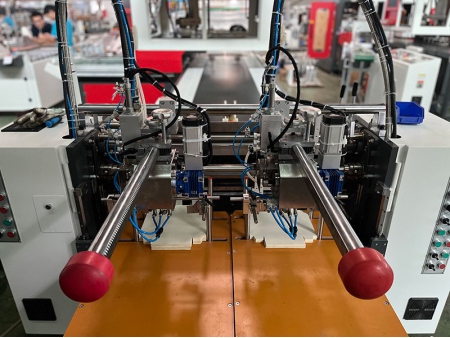

- Independent pressure plates for making boxes of different height.

-

- Four cameras, separately adjustable, allows for high-precision capture of any feature points.

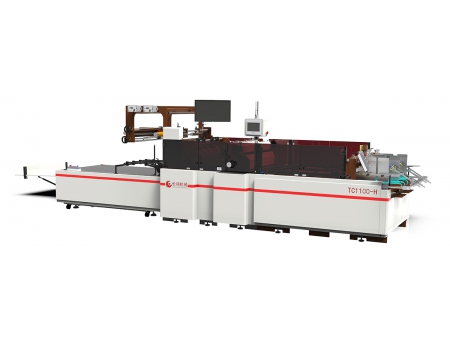

Other Equipment of Rigid Box Line

There are some box making Equipment that we featured for choose your best

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos