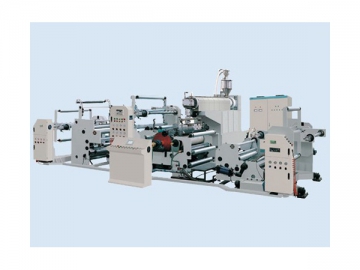

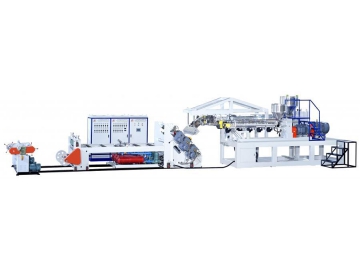

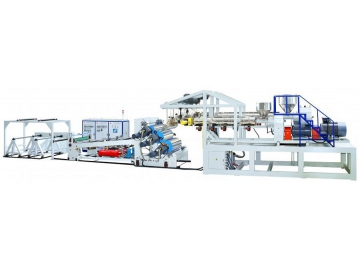

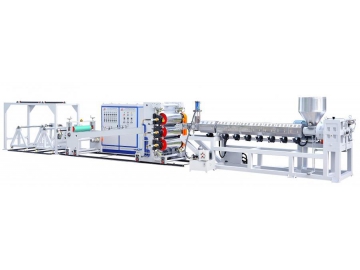

Single Layer/Multi-Layer PE, PP, PS Sheet Extrusion Line

The unique selling point of this sheet extrusion line is its specially designed extrusion screw that has the functions of melting and mixing while maintaining the plastic properties of materials to be extruded. The precise sheet thickness is achieved by a combination of extrusion screw and roller speed adjustments. Independent temperature control system maintains a precise control over the roller temperature, which in turn enables a uniform thickness of the extrudate. The take-up roller is easily reconfigured to meet various customer needs. A drying set-up, for example, can be added to the extrusion line to ensure the extrudate is effectively dried.

Features

1. The coat-hanger type sheet die features a 2-port manifold for precise melt flow control.

2. Accurate temperature control of ±1℃ provides an ideal environment for plasticization. It also helps ensure the uniform thickness of the extrudate.

3. The plastics extrusion die is followed by 3 rolls downstream which are arranged horizontally, vertically, or at an angle of 45°with respect to the ground. The rolls are used to solidify the molten sheet extrudate and impart gloss to the sheet surface. They are vertically adjustable in height, thus providing more options during operation for high quality solidified plastic sheets.

4. Advance sheet cutter allows the exact number of sheets to be cut to the required length.

5. High-torque motor is used to control the sheet take-up speed and tension force on the sheet extrusion line, in an attempt to yield flat rolls of thin plastic sheets. With the aid of the slitter, the finished sheet can be cut to the required width. Via the automatic length counter, users can freely set the sheet length.

The kinds of plastic sheets produced by our plastics mono- or co-extrusion equipment include

1. PE Sheet for Packaging

The single-layer PE plastic sheet, 3-layer extruded PE sheet, and the PE foam core are mainly employed in the plastic packaging industry. PE sheets wrapped around the steel coil provide an ideal water barrier.

2. PP Sheet for Stationery

The transparent PP sheet, frosted sheet, PP foam core, and the 2-color 3-layer extruded PP sheet are widely seen in the stationery industry.

3. PP/PS Blister Packaging

Single-layer PP/PS sheet, 2-layer PP/PS extruded sheet, 3-layer extruded sheet, 2-layer glossy PP sheet

4. Anti-Static or Conductive PP/PE/PS Sheets

Primary uses of our single-layer, double-layer, and 3-layer conductive or antistatic PP/PE/PS sheets are in the semi-conductor, telecommunication, and automobile industries, where they are employed to package the electronic devices for transportation and storage.

Specifications

| Sheet Extrusion Line Model No. | |||

| Sheet Width | 2000mm | 1200mm | 800mm |

| Sheet Thickness | 0.5~2mm | 0.3~2mm | 0. 1~0.8mm |

| Equipment Speed | 15m/min | 20m/min | 20m/min |

| Roller Diameter | Ø600mm | Ø500mm | Ø400mm |

| Production Capacity | 500-600kg/h | 400-500kg/h | 200-300kg/h |