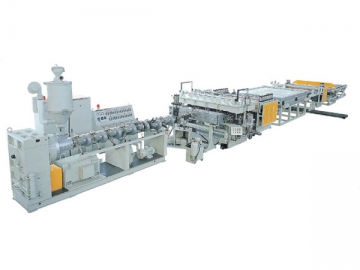

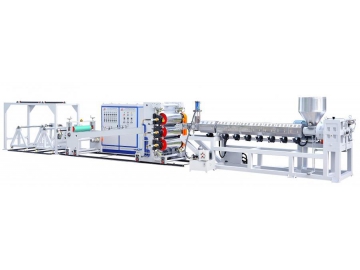

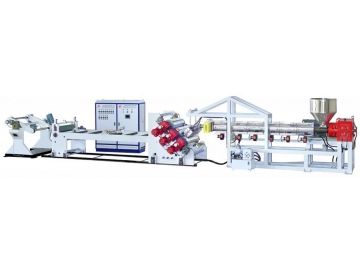

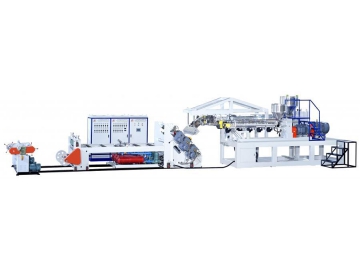

Multiwall Sheet Extrusion Line

The corrugated plastic sheet is made up of what appear to be 3 layers – 2 flat sheets, with 1 ribbed middle layer which is sometimes called the flute. But in fact, they are really 2 layers and sometimes referred to as twinwall sheet. Extra layers can be added to form a multi-wall sheet. HANDERN corrugated sheet extrusion solution is geared towards producing quality corrugated plastic sheets extruded from polypropylene, polyester, and other construction materials. This solution covers all stages of production process, from the raw material handling, through process control, to the finished product quality and production efficiency management.

Our outstanding technical ability is based on more than a decade of experience in the research, development and manufacture of plastics extrusion line. We have what it takes to propose and customize a solution that is sure to meet your specific production and product requirements. Whether you want a standalone device or a complete corrugated sheet extrusion line, HANDERN is able to deliver the right solution that helps you maximize your cost efficiency and equipment service life.

When you order a corrugated sheet extrusion line from us, you are assured of many more benefits including:

1. Required High Production Efficiency

Until your ordered hollow sheet sets deliver the same production efficiency as we have contracted to offer, you don't have to pay full price.

2. Production Flexibility

The product thickness and quality are controllable. You can use the same piece of equipment and mold to produce 2mmm-6mm thick plastic sheets.

3. Reliability and Stability

More than 200 multi-wall sheet extrusion lines are now serving all over the world. HANDERN ranks first for sales in this regard.

4. Adaptability

HANDERN mutliwall sheet extrusion machinery is easily adapted to process different kinds of raw materials, such as the recycled plastics, off-cuts, and leftover bits. Good adaptability allows the equipment to deliver more than 30% production cost savings.

5. Size and Shape Diversity of Finished Product

The finished sheet extrusions come in various shapes and thicknesses.

Products that can be produced by our corrugated plastic sheet extrusion line include:

Thickened Corrugated Plastic Sheet

Offer thicknesses ranging from 8mm to 12 mm to meet evolving customer demands.

Ultra-Thick Corrugated Plastic Sheet

This series of corrugated plastic sheet extrusion line is capable of producing thicknesses between 12mm and 20mm. It can be customized to produce the specific length, width and color of plastic sheets.

Ultra-Thin Corrugated Plastic Sheet

Designed for producing fluted plastic sheets in thicknesses between 1.2mm and 2mm. Customizable for various sheet lengths, widths, and colors.

S-Flute Plastic Sheet Series

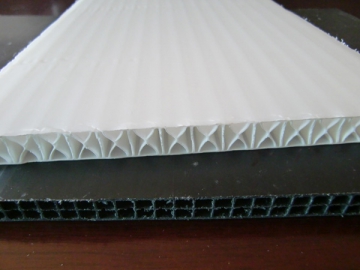

This series of corrugated plastic sheet extrusion line is able to produce plastic sheets with the middle layers that have a unique wavy S pattern. Due to the S-flute structure, the resulting corrugated plastic sheet is tougher than traditional corrugated products. When used as packaging or partition, the sheet can better protect the contents being wrapped.

X-Flute Plastic Sheet Series

The X-flute plastic sheet features a middle ribbed layer that comprises diagonal ribs between vertical ribs. The X-flute pattern gives added stiffness without increasing the sheet thickness and weight. It meets the customer need for extra rigidity.

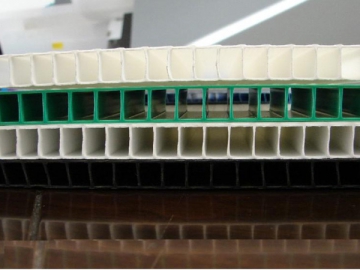

Multiwall Sheet Series

Unlike ordinary corrugated plastic sheets that comprise 2 two sheet layers, the multiwall sheet has extra layers to increase the overall thickness and strength.

PE Corrugated Plastic Sheet Series

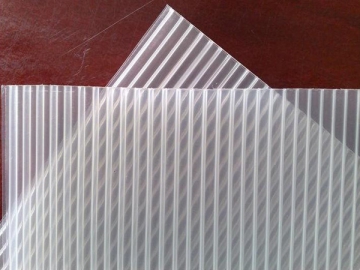

HANDERN PE series extrusion line produces plastic sheets with two insulating cells. This cellular space between sheets provides higher insulating properties than is possible with traditional single-layer plastic film. Framers often use the PE corrugated plastic sheet to build greenhouses. In wintry months, the temperature difference between the outside and inside of the greenhouse can reach 17℃ to 25℃ if the PE sheet is used.

In addition, a rebar structure can be added to the middle layer of the PE fluted plastic sheet to increase its stiffness as well as the resistance to heavy snow and strong wind. The reinforced plastic sheet can stand up to a Grade10 snowstorm or even higher. Durable and economical, the PE corrugated plastic sheet is designed to withstand yellowing, weathering, and high temperatures up to 60℃. If properly maintained, the sheet would last for more than 10 years. Though 5 to 6 times higher than the single-layer plastic film in price, the PE sheet offers a service life 50 to 60 times that of the plastic film. Lightweight yet highly stiff, the sheet is easy to cut and install.