GH019-SA Semi-automatic Sewing Thread Winding Machine

GH019-SA Semi-automatic Sewing Thread Winding Machine

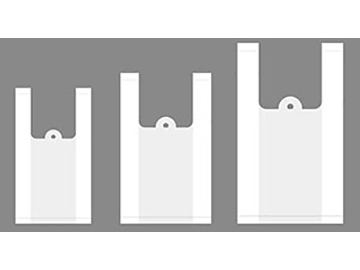

- Sewing thread tubes

for cops for sewing threads with 2" - 6" traverse length

- Sewing thread cones

for a conical package shape with 3" - 4" traverse length

- STSewing yarn

Sewing yarns are especially made to pass rapidly through a sewing machine. They are a fine cord of a fibrous material, which are made of two or more filaments twisted together. The yarns form efficient stitches without breaking or becoming distorted.

- Spun yarnStaple spun yarn

Textile yarn spun twisted from staple length fiber, either natural or synthetic.

- COCotton

Natural fibre from the cotton plant which is spun into fine yarn.

- PET / PESPolyester

Synthetic fiber made from a thermoplastic polymer that contains the ester functional group in their main chain. Most commonly refers to a type called polyethylene terephthalate (PET) or polyethylene succinate (PES) with a melting point from 103 - 106°C.

- CVViscose

Viscose, formerly known as viscose rayon, is made by treating cellulose with caustic alkali solution and carbon disulphide. It is a soft fibre commonly used in dresses, linings, shirts, shorts, coats, jackets, and other outerwear.

- TYTechnical Yarns

The yarns are used for technical textile products, which are manufactured for non-aesthetic purposes. The function such as rigidity, strength, dimension stability, design flexibility and economic viability is main feature.

GH019-SA Semi-automatic high-speed sewing thread winding machine is designed for winding embroidery threads, sewing threads and so on into 4-inch conic or cylindrical package.

| Model | GH019-SA | GH019-ST |

| Shape formation | Conic shape | Cylindrical shape |

| Tube angle | 0°~2°20′ | 0° |

| Max. winding outside diameter | Φ115mm | |

| Spindle number | 4 | |

| Max. linear speed | 1000 m/min | |

| Pattern round number | 3~4 | |

| Parameter No. | Name | Value |

| 0 | Password | 0000~99999 |

| Param-value | ||

| 1 | Full spool length | Range of 0~15000 m |

| 2 | Winding linear speed | 200~1000 m/min |

| 3 | Oil wheel speed ratio | 30~2000 |

| 6 | Winding initial tension | 0~100% |

| 7 | Winding end tension | 0~100% |

| 8 | Yarn-detector state | 0.0~9999″ |

| 9 | Empty spool position confirmation | Computer test value |

| 10 | Fixed block position confirmation | Computer test value |

| 11 | Length correction coefficient | 0.800~1.200 |

- Computer-based yarn length measurement

Non-contact yarn broken detector is sensitive.

Computer-based yarn length automatic measuring system comes with an accuracy of ±0.5%.

Automatic control of winding linear speed is flexibly set within 200-1000 m/min. - Grooved drum yarn guide system offers fast speed and low noise.

Grooved drum is manufactured with special hard material and is treated by hardening and polishing, being smooth and wear-resistant and having no damage to the yarn. - Self-lubrication system

Pump-based cycling-type oiling device allows for the setting of oil wheel speed ratio, ensuring uniform oiling combined with the constant linear speed. Each spindle is always kept at full oil level. Each oil wheel is configured with a filter to prevent oil spray and oil waste. Large return chute and oil deflector block and filter the cotton and return oil generated during the production, without polluting the ground. Movable filter screen is easy to clean. - LED screen is simple to operate

- Oil tank features large capacity, and takes small space. Our semi-automatic winding machine comes with fast speed, high productivity and higher efficiency than traditional winding machines.

- Stainless steel screw

- Full series of imported bearings

- Japan Panasonic converter

- Imported Samsung drive belt