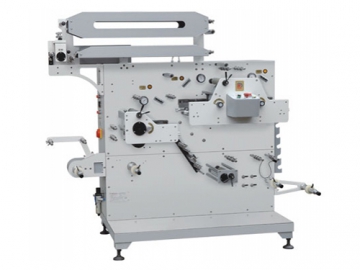

Flexo Printer Slotter Die Cutter (180pcs/min), QYKM Series

The QYKM series of high speed flexo ink corrugated cardboard printing, slotting, die cutting machine is designed for high precision printing with a max DPI of 500-600. These models ofprinting machine for intended for high quality printing operations with lower speed requirements with a 180pcs/min output. This flexo printer slotter die cutter comes in 6 different color options.

Some Samples made by High Speed Flexo Printer Slotter Die Cutter| NO | Parameter name | Unit | Specification |

| QYMW1270X2200 | |||

| 1 | Design speed | Pcs/min | 180 |

| 2 | Width of inside machine | mm | 2400 |

| 3 | Max feeding paperboard size | mm | 1200x2200 |

| 4 | Mini feeding paperboard size | mm | 400x700 |

| 5 | Feeding paper by skip | mm | 1600x2200 |

| 6 | Maxi printing area | mm | 1150x1740 |

| 7 | Over printing precision | mm | ± 0.5 |

| 8 | Printing plate standard thickness | mm | 7.2 |

| 9 | Printing paperboard thickness | mm | 3-11 |

| 10 | Printing roller axle circular adjust | degree | 360 ° |

| 11 | Maxi die cutting size | mm | 1200x2150 |

| 12 | Die cutting thickness | mm | 3-8 |

| 13 | Die cutting precision | mm | ± 1 |

| 14 | Total power(four/five/six color) | Kw | 178/190/202 |

| 15 | Shape size | mm | 9000x4600x3060 |

| mm | 9600x4600x3060 | ||

| mm | 10200x4600x3060 | ||

| Note: all above total power parameter does not include the drying configuration | |||

| NO | Parameter name | Unit | Specification |

| QYMW1270X2500 | |||

| 1 | Design speed | Pcs/min | 180 |

| 2 | Width of inside machine | mm | 2700 |

| 3 | Max feeding paperboard size | mm | 1200x2500 |

| 4 | Mini feeding paperboard size | mm | 400x700 |

| 5 | Feeding paper by skip | mm | 1600x2500 |

| 6 | Maxi printing area | mm | 1150x2040 |

| 7 | Over printing precision | mm | ± 0.5 |

| 8 | Printing plate standard thickness | mm | 7.2 |

| 9 | Printing paperboard thickness | mm | 3-11 |

| 10 | Printing roller axle circular adjust | degree | 360 ° |

| 11 | Maxi die cutting size | mm | 1200x2450 |

| 12 | Die cutting thickness | mm | 3-8 |

| 13 | Die cutting precision | mm | ± 1 |

| 14 | Total power(four/five/six color) | Kw | 178/190/202 |

| 15 | Shape size | mm | 9000x4900x3060 |

| mm | 9600x4900x3060 | ||

| mm | 10200x4900x3060 | ||

| Note: all above total power parameter does not include the drying configuration | |||

| NO | Parameter name | Unit | Specification |

| QYMW1270X2800 | |||

| 1 | Design speed | Pcs/min | 180 |

| 2 | Width of inside machine | mm | 3000 |

| 3 | Max feeding paperboard size | mm | 1200x2800 |

| 4 | Mini feeding paperboard size | mm | 400x700 |

| 5 | Feeding paper by skip | mm | 1600x2800 |

| 6 | Maxi printing area | mm | 1150x2340 |

| 7 | Over printing precision | mm | ± 0.5 |

| 8 | Printing plate standard thickness | mm | 7.2 |

| 9 | Printing paperboard thickness | mm | 3-11 |

| 10 | Printing roller axle circular adjust | degree | 360 ° |

| 11 | Maxi die cutting size | mm | 1200x2750 |

| 12 | Die cutting thickness | mm | 3-8 |

| 13 | Die cutting precision | mm | ± 1 |

| 14 | Total power(four/five/six color) | Kw | 178/190/202 |

| 15 | Shape size | mm | 9000x5200x3060 |

| mm | 9600x5200x3060 | ||

| mm | 10200x5200x3060 | ||

| Note: all above total power parameter does not include the drying configuration | |||

1)The entire machine is constructed from parts that are carefully machined with CNC equipment.

2)German Rexroth servo motors.

3)The touch screen, PLC and inverter feature components designed by Siemens. Low voltage electric parts are constructed from Schneider parts.

4)All bearings are produced by the Japanese manufacturer NSK.

5)Main gears undergo a careful grinding process to ensure high precision transmission.

Feeding unit

Feeding unit 1)Servo auto feeder allows for free pressing feeding.

2)Touch screen interface to show and operate the machine with PLC to communicate with other units.

3)Equipped with an absorption vacuum auxiliary system to ensure a smooth paper feed.

4)Equipped with a counting device and a protective motor starting unit.

5)Electric adjustment of the front, back, left and right baffle.

Printing unit

Printing unit1) Vacuum type paper feeding unit.

2) The printing phase is servo controlled with a ceramic feeding wheel, featuring a long useful life.

3) Steady vacuum paperboard feed with no need for auxiliary pulling paper cushion.

4) Color doctor blade designed by SUN Automation allows for more clear and high quality printing effects.

5) The printing plate roller pahse and lateral adjustment are electrically controlled by PLC.

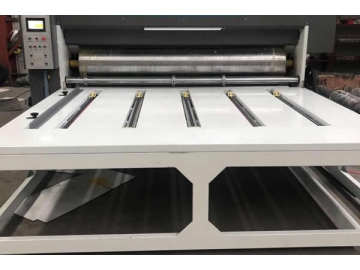

Heating unit

Heating unit 1)Smooth paperboard delivery via vacuum transmission.

2)Quickly heats paperboard after printing to improve machine speed and printing quality.

3)The heating unit prevents dust from the slotting and die cutting enter into printing unit.

4)Infrared and ultraviolet drying methods available to choose from.

Die cutting unit

Die cutting unit 1) Die cutting phase adopts a computerized digital control.

2) The knife mold roller lateral movement adopts an electric adjustment, adjusting range is ±10mm.

3) Rubber roller and knife mold roller gap are electronically adjusted.

4) Knife mold roller is independently servo motor driven.

5) Rubber roller linear speed auto compensation device.

6) Independent servo drive with high precision and efficiency.

Stack unit

Stack unit 1)Platform rises up and down with safety features to protect the operator.

2)Frequency conversion adjustment of the speed drive.

3)The receiving paper belt adopts vacuum absorption transmission neatly stack the paperboard.

4)Fan and brush work together to clear scraps from the slotting unit and die cutting unit.

Related names:

Fiberboard printing unit | Corrugated board production equipment | Cardboard sheet die cutting machine