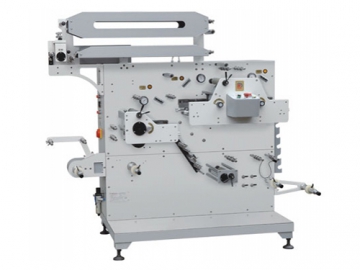

Flexo Printer Slotter Die Cutter (160pcs/min), GYK1370 Series

Main Characteristics of Flexo Printer Slotter Die Cutter

1)Name brand low voltage electric parts.

2)Main bearings are produced by LYC, ZWZ and Harbin

3)Main gears undergo a high frequency quenching process and grinding to ensure high precision transmission.

4)Dual cover design.

5)The wallboard features a cast iron body.

| NO | Parameter name | Unit | Specification | |

| GYK1370X2200 | ||||

| 1 | Design speed | Pcs/min | 160 | |

| 2 | Width of inside machine | mm | 2400 | |

| 3 | Max feeding paperboard size | mm | 1300x2200 | |

| 4 | Mini feeding paperboard size | mm | 400x700 | |

| 5 | Feeding paper by skip | mm | 1600x2200 | |

| 6 | Maxi printing area | mm | 1300X2040 | |

| 7 | Over printing precision(2/3/4color) | mm | ± 0.5/ ± 0.5/ ± 0.75 | |

| 8 | Printing plate standard thickness | mm | 6 | |

| 9 | Printing paperboard thickness | mm | 3-11 | |

| 10 | Printing roller axle circular adjust | degree | 360 ° | |

| 11 | Printing roller axial adjust | mm | ± 10 | |

| 12 | Maxi slotting space | mm | 190x50x190x50 | |

| 13 | Maxi slotting depth | mm | 340 | |

| 14 | Maxi die cutting size | mm | 1300x2100 | |

| 15 | Die cutting thickness | mm | 3-8 | |

| 16 | Total power(2/3/4 color) | Kw | 19/22/27 | |

| 17 | Shape size | Two color | mm | 7000x4000x2400 |

| Three color | mm | 7500x4000x2400 | ||

| Four color | mm | 8000x4000x2400 | ||

| Five color | mm | 9000x4200x2550 | ||

| NO | Parameter name | Unit | Specification | |

| GYK1370X2500 | ||||

| 1 | Design speed | Pcs/min | 160 | |

| 2 | Width of inside machine | mm | 2700 | |

| 3 | Max feeding paperboard size | mm | 1300x2500 | |

| 4 | Mini feeding paperboard size | mm | 400x700 | |

| 5 | Feeding paper by skip | mm | 1600x2500 | |

| 6 | Maxi printing area | mm | 1300X2340 | |

| 7 | Over printing precision(2/3/4color) | mm | ± 0.5/ ± 0.5/ ± 0.75 | |

| 8 | Printing plate standard thickness | mm | 6 | |

| 9 | Printing paperboard thickness | mm | 3-11 | |

| 10 | Printing roller axle circular adjust | degree | 360 ° | |

| 11 | Printing roller axial adjust | mm | ± 10 | |

| 12 | Maxi slotting space | mm | 190x50x190x50 | |

| 13 | Maxi slotting depth | mm | 340 | |

| 14 | Maxi die cutting size | mm | 1300x2400 | |

| 15 | Die cutting thickness | mm | 3-8 | |

| 16 | Total power(2/3/4 color) | Kw | 19/22/27 | |

| 17 | Shape size | Two color | mm | 7000x4500x2400 |

| Three color | mm | 7500x4500x2400 | ||

| Four color | mm | 8000x4500x2400 | ||

| Five color | mm | 9000x4500x2550 | ||

| NO | Parameter name | Unit | Specification | |

| GYK1370X2800 | ||||

| 1 | Design speed | Pcs/min | 160 | |

| 2 | Width of inside machine | mm | 3000 | |

| 3 | Max feeding paperboard size | mm | 1300x2800 | |

| 4 | Mini feeding paperboard size | mm | 400x700 | |

| 5 | Feeding paper by skip | mm | 1600x2800 | |

| 6 | Maxi printing area | mm | 1300X2640 | |

| 7 | Over printing precision(2/3/4color) | mm | ± 0.5/ ± 0.5/ ± 0.75 | |

| 8 | Printing plate standard thickness | mm | 6 | |

| 9 | Printing paperboard thickness | mm | 3-11 | |

| 10 | Printing roller axle circular adjust | degree | 360 ° | |

| 11 | Printing roller axial adjust | mm | ± 10 | |

| 12 | Maxi slotting space | mm | 190x50x190x50 | |

| 13 | Maxi slotting depth | mm | 340 | |

| 14 | Maxi die cutting size | mm | 1300x2700 | |

| 15 | Die cutting thickness | mm | 3-8 | |

| 16 | Total power(2/3/4 color) | Kw | 19/22/27 | |

| 17 | Shape size | Two color | mm | 7500x4800x2550 |

| Three color | mm | 8000x4800x2550 | ||

| Four color | mm | 8500x4800x2550 | ||

| Five color | mm | 9000x4800x2550 | ||

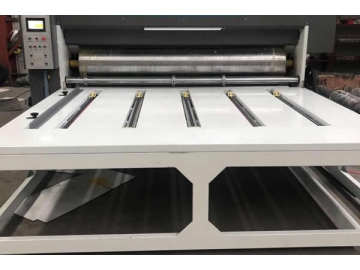

Feeding unit

Feeding unit1)Auto feeder design

2)Easy to operate speed adjustment table

3)Equipped with an absorption vacuum auxiliary system to ensure bending paper can feed smoothly.

4)Equipped with a counting device and motor protection device.

5)Quick roller gap adjustment and self-locking device.

Printing unit

Printing unit1)Metal anilox roller with optional ceramic roller upgrade.

2)High quality rubber roller.

3)Touch screen interface to perform phase adjustments and other operating procedures.

4)Quick roller gap adjustment with a self-locking device.

Slotting unit

Slotting unit1)Touch screen for electronic adjustment

2)Carton box size is manually adjusted.

3)Electronic phase adjustment.

4)Quick roller gap adjustment with a self-locking device.

Die cutting unit

Die cutting unit1)Duramax rubber cushion designed in Taiwan ensures a long useful life.

2)Touch screen for operation and phase adjustment.

3)Mechanical cam structure for precise cuts every time.

4)Quick adjustment of the roller gap with a self-locking device.

Stack unit

Stack unit1)Protection devices are installed to protect the operator.

2)The back baffle position is manually adjusted.

3)Chain driven.

4)1600mm stack height.

Corrugated fiberboard flexo printer | Cardboard cutter | Cardboard sheets making machine