Energy Saving Laminator GF800A/1100A

Request a Quote

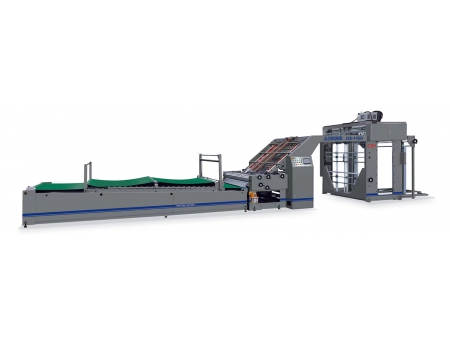

Deguang energy saving laminator is ideal for BOPP, PET, CPP, PC, PVC, al-plated film, aluminum coil, and the composite film and paper with the same properties. Its mechanical speed is80m/min.

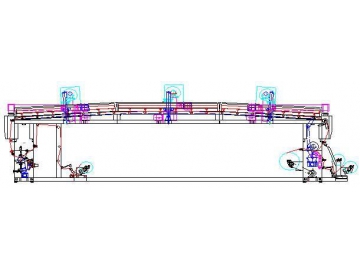

Energy Saving Laminator Configuration- Main transmission unit: It adopts AC variable frequency vector control. The glue spreading rubber roller and hot drum are synchronized in terms of speed and use the swing arm to control the tightness and looseness of the film in the oven channel.

- Material feeding device: Group one and two feeding devices use photoelectric edge-correcting device and adopt manual tension control.

Rubber spreader: The anilox rollers control the amountof spread through doctor blades. The rubber roller adopts dual air cylinder to increase the pressure. The laminating film can lift automatically while the energy saving laminator stops. - Oven tunnel: The tunnel is divided into four sections, temperatures of which are independently controlled by the intelligent temperature controller. The tunnel is equipped with an inner circulation device for reusing hot air. The material-protecting roller and the hot drum can rotate synchronously.

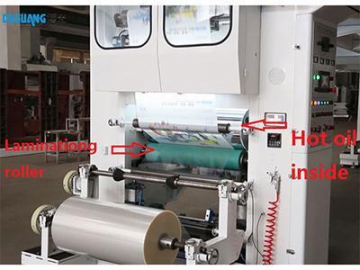

- Laminating hot drum and impression roller: The laminating hot drum is heated using heat conducting oil, which results in great heating uniformity and low electricity consumption. The impression roller is controlled by dual air cylinder and the pressure can be adjusted freely

- Material-receiving device: It is a linkage material-receiving device, and a moment motor is used to receive materials.

- The Frequency Inverter (From Huichuan)

- The Air Cylinder (FromTaiwan)

- The Switch (FromShanghaiErgong)

- The Low-Voltage Electricity (From Zhengtai Delixi)

- The Temperature Controller (From Yuyao)

- Anilox Roller (From Yuncheng)

- The Moment Motor (FromChina)

| Model | GF-800A | GF-1100A |

| Laminating layers | 2 | 2 |

| Laminating width | 800mm | 1100mm |

| Diameter of material cylinder | 600mm | 600mm |

| Adjustable range of laminating linear speed | 50-80m/min | 50-80m/min |

| Max. adjustable temperature of drying oven | 80℃ | 80℃ |

| Max. adjustable temperature of hot drum | 70℃-90℃ | 70℃-90℃ |

| Tension ratio | ≤1/1000 | ≤1/1000 |

| Total power | 48kw | 64kw |

| Weight | 5000kg | 5500kg |

| Overall dimensions (L×W×H) | 7500×1960×2550 | 7500×2260×2550 |

Thanks for your interest in our website! We at Deguang Machinery are a professional laminating machine manufacturer, based inChina. The product shown on this page is our energy saving laminator. In order to meet every customer's needs, we also produce automatic dry laminating machine, automatic high speed slitting machine, high speed rotogravure printing machine, and more. All these products are CE certified and have passed the test of market. We sincerely hope buyers and agents from all over the world can contact us and cooperate with us!

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos