JK810-3

- Borehole diameter: 90-165mm

- Drill rod length: 4m

- Walking speed: 2.2 (low speed) 3.5 (high speed)

- Optional: Automatic lubrication system for drill rods

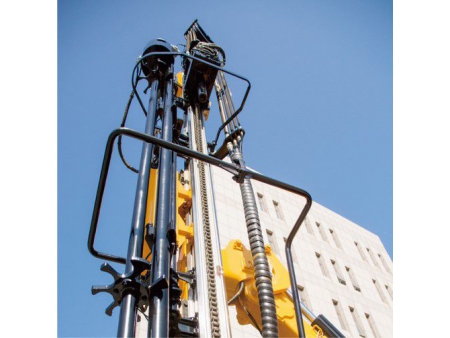

JK810 integrated hydraulic DTH drilling rig features strong automation capability, reliable drilling performance, user-friendly operation and green drilling methods. The rig is equipped with a FOPS-certified cabin and automatic rod exchange system. Heavy-duty undercarriage with wide tracks ensures both maneuverability and safety. The hydraulic dust collecting system meets the environmental protection regulations, which makes it a reliable solution to realize the modern green mining.

Applications

The integrated drilling rig is mainly applied for hydro-power engineering, open pit mining, road construction and blasting operation of national defense engineering.

| Model | JK810-3 | ||

| General | Weight | kg | 18000 |

| Length | mm | 9920 (transport) | |

| Width | mm | 2700 | |

| Height | mm | 3300 | |

| Undercarriage | Track width | mm | 350 |

| Ground clearance | mm | ≥400 | |

| Track oscillation | ° | ±10° | |

| Walking speed | km/h | 2.2 (low speed) 3.5 (high speed) | |

| Grade ability | ° | 20° | |

| Engine | Model | QSL8.9-C360-30 | |

| Type | Water-cooled 6-cylinder EFI diesel engine | ||

| Rated power | kW/rpm | 264/2100 | |

| Fuel tank capacity | L | 450-500 | |

| Air compressor | Model | Atlas Copco two-stage rotary screw air compressor | |

| Working pressure | bar | 20 | |

| Max. free air delivery (FAD) | m³/min | 19.8 | |

| Rotary motor | Rotation rate | rpm | 0-160 |

| Max. rotation torque | Nm | 3300 | |

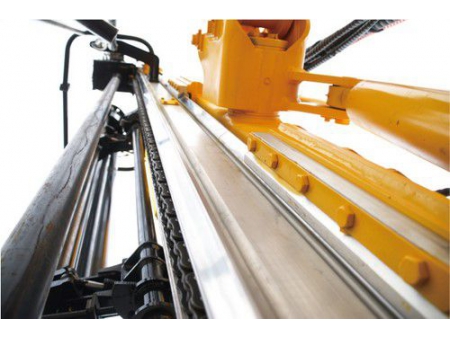

| Feeding method | Hydraulic motor chain | ||

| Feeding force | kN | 12 | |

| Lifting force | kN | 18 | |

| Feed | Feeding stroke | mm | 4750 |

| Feed extension | mm | 1100 | |

| Drill rod changer | Drilling diameter | mm | Ø90 - Ø165 |

| Drilling depth | m | 28 | |

| Rod diameter | mm | Ø76/ Ø 89 | |

| Rod length | m | 4 | |

| Rod capacity | piece | 6 1 | |

| Hammer specs | 4' - 5' | ||

| Dust collector | Collecting method | Hydraulic dust collecting | |

As mining technology is developed, the number of drilling methods is increasing. The common drilling methods include auger drilling, rotary air blasting, reverse circulation drilling, diamond core drilling, blast hole drilling and hydraulic rotary drilling.

The DTH system is applicable to a wide range of rocks, including soft, medium hard and extreme hard rocks, and various formations.

We thrive on building collaborative partnerships with the world's miners. If that sounds like you, we'd love to talk.