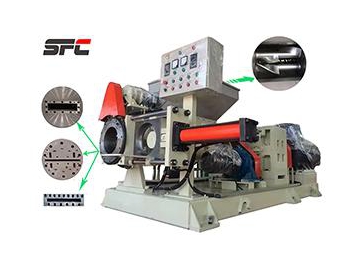

Silicone processing machinery is suitable for various applications in silicone production, including silicone product manufacturing, silicone seal strip production, silicone seal ring manufacturing, silicone seal gasket production, medical rubber product manufacturing, and more. It can be used for filtering different hardness levels and mesh sizes of silicone materials.

Yes, our silicone strainer is designed to meet the filtration needs of silicone with different hardness levels and mesh sizes. The silicone strainer can accommodate silicone materials of various specifications and characteristics to provide precise filtration results.