Manure Removal System

Whether you are running cage or floor poultry production, the manure removal system is an ideal choice to keep your poultry house well clear of manure. It is easy to operate and provides high practicality. Currently, wide applications of this manure removal solution have been found in layer, broiler, quail, duck, geese and other poultry houses as well as pig, sheep, cow and other domestic animal farms. Each set of the manure belt system can be designed with 2-3 manure channels and the manure scraper size is determined by the channel size.

- Manure Belt

Working Principle

Power is transmitted from the motor to the main drive wheel via chains or triangle belts. By a traction rope, the drive wheel drives the scraper to move forward and backward to complete the manure removal job.

| Types | Fully automatic manure removal system with single manure channel | Fully automatic manure removal system with double manure channels | Fully automatic manure removal system with 3 manure channels |

| Main equipment | Includes: One set of 3kW copper wire motor; 4 worms and gear s x 1 reducer; 1 motor base | Includes: One set of 3kW copper wire motor; 4 worms and gears x 1 reducer; 1 motor base | Includes: One set of 3kW copper wire motor; 4 worms and gears x 1 reducer; 1 motor base |

| Pulley | 2pcs | 4pcs | 8pcs |

| Manure scraper | 1 set: 1 scraper and 1 iron stand | 2 sets: 2 scrapers and 2 iron stands | 3 sets: 3 scrapers and 3 iron stands |

| Power supply: Available in single phase 220V and three-phase 380V | |||

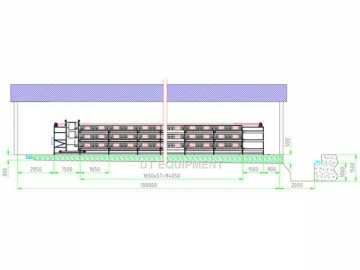

- Manure Removal System for A-Frame Cage System

- Manure Removal System for A-Frame Cage System

- Manure Removal System for H-Frame Cage System

- Manure Removal System for H-Frame Cage System

Safety Precautions

1. Before first use of our manure removal system, please read the manual in detail and know its working principle and safety precautions.

2. Installation, adjustment, maintenance and repair must be carried out under power-off condition to ensure safety.

3. Before use after a long period of downtime, please conduct proper adjustment and maintenance according to the manual. During use, regularly check the reliability and sensitivity of electrical parts and check if the bolts, chains or triangle belts are loose.

4. Do not refit the drive system and change its gear ratio at will.

5. Teenagers of less than 16 years old and those who do not grasp how to use are not allowed to operate the poultry equipment alone.

6. Ground connection of the motor shell must be reliable.

7. Chains, triangle belts and traction ropes are dangerous when the machine works, so please be not close to them.

8. The manure equipment has to be installed in dry place to protect electrical parts from moisture. When it is placed outside, please make reliable rain-proof measures.

Installation and Attentions

1. Installation

1) The fixing device of main machine should be buried under cement ground to a depth of 50cm in case that overlarge tension will pull it out.

2) Outer tangent line of the pulley should coincide with the center line of manure channel so as to prevent scraper deviating.

3) Before use, inject 1.5L gear oil into the reducer. Too much or too less oil should be avoided for that will overheat the reducer.

4) During use, keep the hole on the plug of oil inlet smooth.

5) Generally, depth of manure channel is 30-50cm.

2. Attentions

1) The motor and pulley have to be firmly and reliably fixed to prevent loosing during operation.

2) Tension the rope meticulously.

3) The limit switch should be fixed at the end of manure channel where the scraper stops.

4) For the control cabinet equipped with time switch and motor protector, you have to set the switch at manual mode to prevent its automatic start during installation. After installation and commissioning, set the time switch according to manual.

5) Because of the motor protector, you can not install the circuit until the motor is connected. Otherwise, the protector is considered to be at default phase state, resulting that the contactor will not close.

6) The traction rope comes with elasticity, so it has to be checked regularly to avoid loosing and slipping.

Use and Maintenance

1. Before use, fill 30# lubricating oil into cycloidal speed reducer up to the middle part of oil window and fill 1.2-1.5L 50# oil into worm speed reducer. Change oil every three months.

2. Clean the manure scraper 2-3 times a day and clean more if the manure channel is too long.

3. Check the oil once a week and add when it is insufficient. Weekly, instill lubricating oil to the drive chains.

4. Monthly, check the tension of chains and ensure the middle part lowers at most 3-5mm.

5. Examine the manure scraper every week and timely clean up manure accumulated on it.