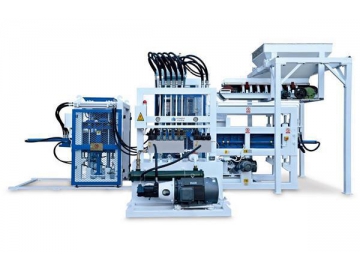

Concrete Block Making Machine, QT6-15

Technical Parameters of QT6-15 Concrete Block Making Machine

| Vibration frequency | 3800-4500 times/sub | ||||

| Total weight | 8500kg | ||||

| Overall dimension | 9450×3300×2700mm | ||||

| Installed capacity | 31.4kW | ||||

| Cycle time | 15-20s | ||||

| Rated pressure | 25Mpa | ||||

| Exciting force | 68kN | ||||

| Plate specification | 880×680×20mm | ||||

| Molding way | Vibration extrusion forming | ||||

| Stacker capacity | 3kW | ||||

| Block | Hollow block | Solid brick | Porous brick | Pavement brick | |

| Picture |  |  |  |  |  |

| Size | 390×190×190 | 240×115×51 | 240×115×90 | 200×100×60/80 | 250×250×60 |

| Molding blocks | 6pcs/mold | 32pcs/mold | 15pcs/mold | 18-21pcs/mold | 6pcs/mold |

| Molding cycle | 15~20s | 20~30s | |||

| Per hour production | 1080pcs/1h | 5760 pcs/1h | 2700pcs/1h | 3240pcs/1h | 1080pcs/1h |

| Class production | 8640- 11520pcs/8h | 46080- 61440pcs/8h | 21600- 28800pcs/8h | 27000pcs/8h | 8640- 11520pcs/8h |

| Excitation frequency | 50~60Hz | ||||

| Block height | 50~200mm | ||||

| Power of main motor | 31.4kW | ||||

| Machine size | 9450×3300×2700mm | ||||

| Machine weight | 8500kg | ||||

**Note: The above parameters are for reference only. Modifications and upgrades are available. Please contact us for more information.

Features

1. The QT6-15 concrete block making machine is designed with integrated vibrating and molding platforms, which reduces the connecting area and improves the vibration efficiency.

2. The distance between the eccentric shafts are widened to provide a larger and more efficient vibration area for the concrete block production equipment.

3. An airbag cylinder clamping system prevents the concrete block making machine from shaking while working, while also controlling the forming weight and height. Because of this design, noises caused by vibration are reduced.

4. Changing the molds is quick and easy, allowing this machine to be a multi-purpose brick making machine that can be used to produce a variety of bricks.

5. Movement sensors (electronic slide rules) are used to control the precise movement between the tamper head and the mold.

Maintenance

In order to extend the service life of the concrete and block making machine, the following list should be read carefully.

1. Do not store raw materials in the hopper for extended periods of time as the cement will harden quickly.

2. When loading or feeding the raw materials into the automatic block making equipment, ensure there are no large aggregates or other impurities, especially hard iron objects, mixed into the raw materials. Those impurities can damage the molds and mechanical parts of the machine.

3. Check and keep the pallets clean. Remove hardened materials from the pallets before feeding them into the machine.

Pictures of Details

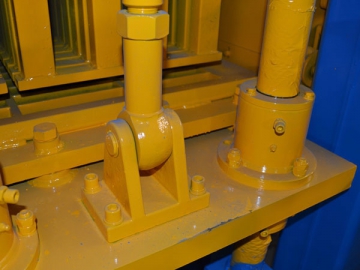

- Hydraulic part

- Temperature scale of hydraulic system

- Material loader 3

- PLC inside

For more molds and samples, please click ""