Tower Crane QTZ160

General introduction

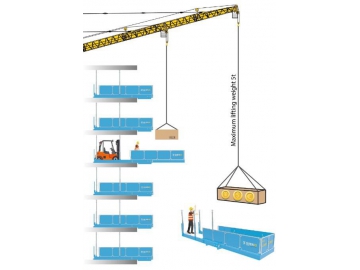

The hammerhead tower crane features a horizontal support arm, trolley, top slewing, and hydraulic climbing. Its maximum load is 10t, rated load moment is 1600kN·m, and maximum load moment is 1842kN·m.

Features of the hammerhead tower crane

1) Advanced performance and technical parameters.

2) Aesthetically designed with a maximum working radius of 60m, increasing the work space of the top slewing crane.

3) A variety of stationary and attached tower cranes can be used for different construction sites. Freestanding height is 50m. With attachments, height can be 180m (2 falls) or 90m (4 falls).

4) High working speed while remaining stable and efficient.

Hoisting mechanism uses a multi-speed winding motor and single speed reducer for large loading. Its maximum speed is 104 m/min.

Slewing mechanism uses a winding motor, planetary gear reducer, and hydraulic couplings for high loading capacity, good stability, and wind resistance.

5) The hoisting jib has rigid double drawing bars and is lightweight, compact, and wind-resistant.

6) Equipped with various safety devices to guarantee that the hammerhead cranes work stably.

7) The cab of the construction machinery has a wide field of vision and is comfortable and convenient to operate within.

8) Easy to install and maintain.

Without a balanced weight, foundation and anchors, the QTZ160 hammerhead tower crane weighs 60.463t and has a total capacity of 78.5 Kw. This hoisting equipment is widely used in construction projects for high-rise hotels, residential housing and industrial buildings.

Technical parameters of the hammerhead tower crane| Item | Unit | 2 falls | 4 falls | |||

| Rated lifting torque | kN.m | 1600 | ||||

| Max. lifting capacity | t | 5 | 10 | |||

| Working range | m | 3 ~ 60 | ||||

| Lifting capacity at Max. range | t | 2.461 | 2.439 | |||

| Range at Max. lifting load | m | 33.8 | 18.4 | |||

| Lifting height | Independent | m | 50 | |||

| Adhered | 180 | 90 | ||||

| Lifting speed | m/min | 104/50.05 | 52.05/25.02 | |||

| Slewing speed | r/min | 0.61 | ||||

| Trolleying speed | m/min | 58.6/29.3/8.79 | ||||

| Jacking speed | 0.4 | |||||

| Min. speed of steadily declining | ≤5 | |||||

| Height | Foundation frame | m | ||||

| Height of the overall machine (independent) | 60.44 | |||||

| Tip of jib to the slewing center | 61.384 | |||||

| Tip of balanced jib to the slewing center | 15.22 | |||||

| Overall weight | Structure weight | t | 60.463 | |||

| Counterweight | Max. radius =60m | 23 | ||||

| Max. radius =56m | 21 | |||||

| Max. radius =50m | 17.8 | |||||

| Total capacity of motors | KW | 78.5 | ||||

| Allowable work temperature | ℃ | -20 ~ 40 | ||||

| Basic wind pressure in service | Pa | 250 | ||||

| Basic wind pressure out service | Pa | 1100 | ||||

| Power supply | 50Hz | ~ 380V ± 10% | ||||

| Mechanical load factor | Hoisting mechanism | M5 | |||

| Slewing mechanism | M4 | ||||

| Trolleying mechanism | M4 | ||||

| Hoisting mechanism | Motor | Type | YZRDW280M-4/8-55/55 | ||

| (kW) power | 55/55 | ||||

| Height limiter | Type | FKDX-G | |||

| Steel wire rope | Specification | 6X37-16-1770- Ⅰ | |||

| (N) maximum tractive force | 25000 | ||||

| Magnification | a=2 | a=4 | |||

| (m/min) hoisting speed | 104 | 50.05 | 52.05 | 25.02 | |

| (t) rated load | 2 | 4 | 5 | 10 | |

| Min. speed of steady declining | m/min | ≤5 | |||

| Slewing mechanism | Motor | Type | YZR160M1-6 | ||

| (kW) power | 5.5×2 | ||||

| (r/min) speed | 908 | ||||

| Reducer | Type | XX4-120AI | |||

| Transmission ratio | 195 | ||||

| Hydraulic coupler | Type | YOX280A | |||

| Slewing pinion gears | No. of modulus | 12 | |||

| No. of teeth | 19 | ||||

| Modification coefficient | + 0.5 | ||||

| Slewing speed | r/min | 0.61 | |||

| Slewing bearing | Single row four points contact ball type slewing bearing | Type | 011·50·1600 | ||

| No. of modulus | 12 | ||||

| No. of teeth | 151 | ||||

| Hydraulic jacking mechanism | Motor | Type | Y132M-4-B5 | ||

| (kW) power | 7.5 | ||||

| Rated work pressure of cylinder | MPa | 30 | |||

| Cylinder stroke | mm | 1600 | |||

| Locating distance | mm | 2150 | |||

| Dia . of cylinder | mm | φ180 | |||

| Dia . of cylinder piston rod | mm | φ120 | |||

| Jacking speed | m/min | 0.4 | |||

| Trolleying mechanism | Motor | Type | YZTDE180M-4/8/24 | ||

| (kW) power | 5/3.7/1.1 | ||||

| Steel wire rope | Specification | 6X19-9.3-1550- | |||

| Reducer | Type | XX3-14.40 | |||

| Transmission ratio | 39.7 | ||||

| Trolleying speed | m/min | 58.6/29.3/8.79 | |||

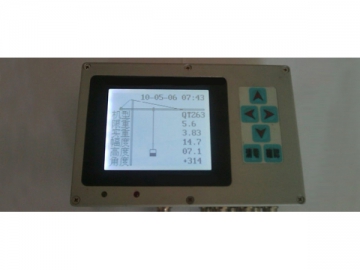

Safety-protection device

According to the GB5144 safety regulations for tower cranes, we equip our hammerhead tower cranes with safety-protection devices such as the moment limiter, overload limit switch, over hoist limit switch, slewing limit switch, trolley limit switch and anemoscope.

Structure

Computer-aided, optimal design guarantees the strength, rigidity, and wear-resistance of the tower crane’s structure.

The tower section of TC6516 is a sheet structure with treated pivots that connect tower sections. The main stand bar is a square-shaped steel tube structure made with submerged-arc welding. The hammerhead tower crane is reliable, reducing the whole load and raising stability. The square steel tube is wind-resistant and rigid.

Main parameters| Item | Performance | Parameters |

| 1 | Max. Load | 10t |

| 2 | Max. jib length | 65m |

| 3 | Tip load | 1.6t |

| 4 | Free standing height | 50m |

| 5 | Max. height | 200m |

| 6 | Size of mast section | 1.835×1.835 ×2.8m |

| 7 | Material of mast section | ∠ 140×14, manganese steel |

| Work rank of whole crane | A4 | Work rank of mechanisms | Hosting mechanism | M5 | ||

| Slewing mechanism | M4 | |||||

| Trolleying mechanism | M4 | |||||

| Hoisting height(m) | Free standing=53 | Attached=200 | ||||

| Max. load | 4 falls=10t 2 falls=5t | |||||

| Radius(m) | Max. radius | 65 | ||||

| Min. radius | 2.5 | |||||

| Tip load (t) | 1.6 | |||||

| Hoisting mechanism | Speed | Magnification | α=2 | |||

| Load (t) | ≤2.5 | ≤5 | ||||

| Speed (m/ min) | 100 | 50 | ||||

| Magnification | α=4 | |||||

| Load (t) | ≤5 | ≤10 | ||||

| Speed (m/ min) | 50 | 25 | ||||

| Type of motor and power | TZRSWF250M2-4/8 37kW | |||||

| Slewing mechanism | Speed | Type of motor | Power | |||

| 0.56r/min | YTW132S-4 | 5.5kW×2 | ||||

| Trolleying mechanism | Speed | Type of motor | Power | |||

| 60/30/9 | YDEG180-4/8/24 | 5/3/1 .1kW | ||||

| Jacking mechanism | Speed | Rated work pressure | Power | |||

| 0.5m /min | 20MPa | 7.5kW | ||||

| Counterweight | Jib length(m) | 65 | 60 | 55 | 47.5 | |

| Weight (t) | 24 | 21.9 | 21 | 16.5 | ||

| Total power | 53kW (without jacking motor) | |||||

| Power supply | ~ 380V(±5%) | Frequency | 50Hz | Work temperature | –10 ℃ ~ 40 ℃ | |