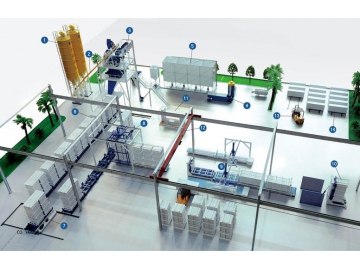

Automatic Production line for Steel Light Pole

This set of equipments is the most economical configuration. Our automatic line for steel light poles offers high efficiency and reliable quality, allowing to obtain unpolished steel poles from raw materials without you having to intervene at any moment.

Lamp Post Production Line Components:

1.T44Q-6×1800 Processing Line

2.ZQ11-6×2400×14000 Diagonal Shear Steel Plates Production Line

3.2-WE67K-400/7000 Tandem CNC Press Brake

4-1. HFH320×5-14000 Automatic Welding Line

4-2. HFH550×8-14000 Automatic Welding Line

5. HF600×8-14000 Mechanical Seaming Machine

6. MZ630SS-14000 Semi-automatic Welding Line

7. W31Y-600×10 Steel Straightening Machine

8-1. WG90×4 Tube Bending Machine

8-2. WG100×4 Tube Bending Machine

9. ZDMJ-350×14000 Automatic Grinding Machine

10. ZJP-14000 Electrostatic Spray Painting Line

Customers can order from the above list based on their specific production needs. Please contact us for any advice. We will help you to find the best solution.

Process Flow

1. Coil feeding → 2. Coil processing → 3. Steel plates cut diagonally into trapezoidal type → 4. Transfer of materials to be bent → 5. Plate bending on press brake → 6. Transfer of poles with seams to the submerged arc welding line → 7. Steel poles straightening → 8. Flange Welding → 9. Pole bending and forming → 10. Transfer of poles for galvanization → 11. Spraying (according to request) → 12. Lights installations → 13. Delivery and installation

Workshop Area

This production line requires from two to three 60000×18000MM rooms with a stacking area and a welding area. We can design the plant according to the users' available area to ensure a smooth run of the production line. It requires a power of 150 kW.