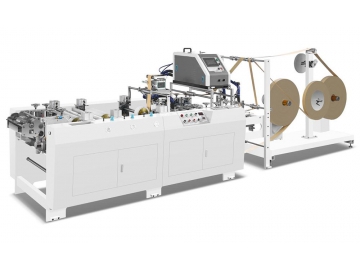

Semi-Auto Stitcher

Transmission and operation of the entire semi-automatic stitching machine uses two servo drive motors to drive the feeding portion of the machine operation, mechanical portions, needle head portion and the rear portion of the shutter drive. The mechanical tailgate is easily and directly adjustable using touch screen operation. This is accurate and convenient, requiring no employees to manually adjust the size of the machine. Operators can easily use the gears and bearings to drive mechanical operations and reduce the failure rates of the machinery, while prolonging the service life. The double servo drive is ideal for semi-automatic carton manufacturing equipment.

Uses and Characteristics

1.The double servo motor is imported. It features accurate precision, less machinery transmission and reduces possible machine faults.

2.The semi-automatic stitching machine is operated using a touch screen. All parameters (needle distance, needle quantity, back baffle) are quickly adjustable.

3.The control system is a Siemens PLC control system.

4.The back electric baffle uses a step by step drive, accurate sizing, and makes it easy to change the size as needed.

5.All contactors in the control box are also from Siemens.

6.The optoelectronic switches and approach switches are a Korean brand.

7.The die blocks and blades are made using Japanese special tungsten steel.

8.The entire needle head uses a special steel that has been cured using a computer and features a high precision.

9.This stitching machine can use a single needle, double needle or fortified needles to satisfy different customer requirements.

10.It can change the size and distance of the needles in a single minute.

11.The machine can stitch both covered and non-covered cartons, though customers should specify which the machine will be used for upon ordering.

12.Front feeding into the machine is automatic. The feeding platform has photoelectric sensors, and automatically rises when feeding paper board into the machine.

13.The end of the machine also has an automatic counting feature. The paper board will be transported to the machine end according to preset quantity, making packing easy and convenient.

14.When there are no needles, the machine will automatically warn operators.

| Max. paper size(A B)*2 | 2460mm |

| Min. Paper size(A B)*2 Min. | 606mm |

| Max. Paper Length(A) | 1050mm |

| Min. Paper Length(A) | 120mm |

| Max. Paper width(B) | 606mm |

| Min. Paper width(B) | 180mm |

| Max. Paper height(C D C) | 1515mm |

| Min. Paper height(C D C) | 300mm |

| Min first stitching pitch(D) | 25mm |

| Max TS width(E) | 35mm |

| Stitching pitch | 30-120mm |

| Qty. of stitching | 1-99pcs |