Granulation and Coating Machine

The fluid bed granulator takes the powder material and feeds it into the fluid bed where it is put in a state of annular fluidization. It is preheated and mixed with clean and heated air. During this time, a solution of adhesive solvent is sprayed into the container to make the particles become granules. The moisture in the granule is then evaporated and the adhesive solidifies.

The FLP fluid bed granulator and coater was designed to create granular solids from pumpable and atomizable fluids such as pastes and slurries. These coaters are commonly applied in various medicine, food and other industries.

1. The spray dryer granulator features simultaneous spraying, drying/fluid granulating within its chamber.

2. The spraying process makes the granulating machine suitable for micro auxiliary raw materials and thermally sensitive raw materials.

3. The moisture of final products can reach as low as 0.1%. The granulator is equipped with a powder recovery device.

1. The granulating machine features a horizontal cylinder structure.

2. Uniform granule structure.

3. The machine can perform its granulating and drying functions with 25% less adhesive compared to traditional machines.

4. 2 minutes for mixing time and 1-4 minutes for granulating. This is 4-5 times more efficient than traditional granulators.

The GK series dry granulator is engineered to form granules directly from the raw material with the minimum amount of water. These granulating machines are found in pharmaceutical, food, and chemical industrial applications. Some materials are sensitive and cannot be exposed to wet granulating methods. The finished granules from this granulating equipment can be used for troches or capsules.

The GZL series dry granulator employs dry roll-extruding technology to compress powder materials with a moisture content below 10%. The machine then sifts and fragments the material until the granule size requirements are met. The density of material increases 1.5-3 times during the extrusion process.

The basket extruder or basket granulator is primarily applied in pharmaceutical, food and chemical production. The granulating machine can take stirred raw materials and form uniform granules, especially for materials that contain adhesives.

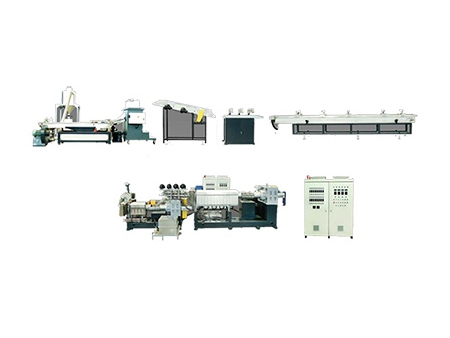

The SE series screw extrusion granulator comes in both a single-screw and double-screw type. These granulating machines are designed for wet material or materials with low melting points after a kneading and mixing process. The screw drives the material to push it through the mold plate. The diameter of the end grain can be chosen and controlled by changing the openings in the mold plate.

The spheronizer is fitted with a blower controlled by an inverter device.

The rotor dish of the granulator uses a double speed motor that leads to uniform pellet granules.

The granulating process is completed in a sealed structure that keeps all dust inside.

The oscillating granulator is suitable for pharmaceutical, chemical and food applications to form granules of varying specifications. After a drying process, the granulator presses the material into different shapes. It can also be used to crush blocks of raw material.

The grinding granulator produces uniform granules with less heat and dust. The fixed screen is made from durable stainless steel. The gap between crush knives and screen can be adjusted. It can treat adhesive coated, hot and wet raw materials.