Descriptions

The spin flash dryer is new piece of high efficiency drying equipment that was developed to overcome the low-efficiency and high energy consumption of static drying devices. During the design process, we made several improvements on existing drying technologies in order to maximize the drying effectiveness of the machine with minimal energy consumption.

Principle of Work

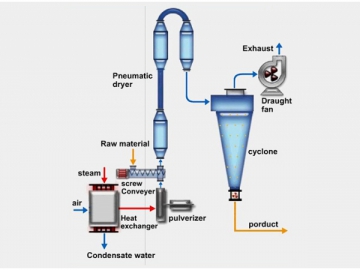

Hot air enters into the stirring, crushing and drying chamber from the bottom of the dryer and quickly heats the space. The raw material undergoes strong shearing, blowing and rotating effects within the centrifuge, which results in the desired granulation effects. At the bottom of the dryer, the large and damp granules will be crushed by the stirrer until the granules are small enough to be lifted by the air stream. The heated air creates an effective heat exchange and quickly dries these granules.

Features

1. There are several choices of feeding equipment that can be either continuous or static.

2. At the bottom of dryer, where the temperature is highest, heat sensitive raw material will not come in contact with the heat surface directly, thereby solving the carbonized and changed color problems of heat sensitivity raw material.

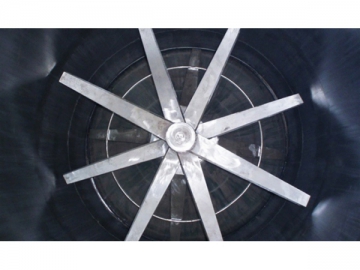

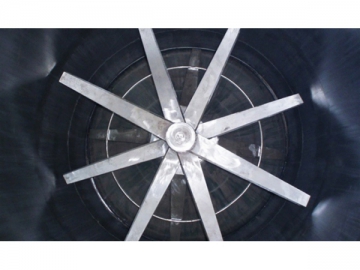

3. Specially designed air flow equipment.

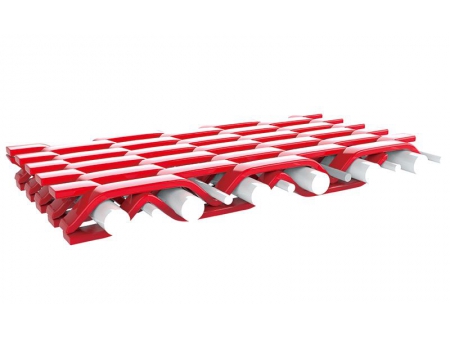

4. There are rotational flow pieces inside the drying chamber. It is used to control the moisture and granules of raw material.

5. Because the gas speed at circle inside the drying chamber is high and the staying time of raw material is short, high efficiency and quick speed can be realized.

Application

Organic compounds: Fenatrol (insecticide of agrochemicals), cadmium laurate, benzoic acid, germicide, sodium oxalate, cellulose acetate, etc.

Dyestuff: anthraquinone, black ferric oxide, indigo blue pigment, butyric acid, titanium hydroxide, zinc sulfide, all kinds of intermediate of azo dye-stuff.

Inorganic compounds: borax, calcium carbonate, hydroxide, copper sulfate, ferric oxide, barium carbonate, antimony trioxide, all kind of metallic hydroxide, all kinds of heavy metallic salt, synthetic cryolite , etc.

Ceramics: kaoline, silicone trioxide, clay, etc.

Foodstuff: soya protein, agglomerative starch, lees, triticin, wheat starch, etc.

Technical Parameters

Model Selection