Medium Voltage Drive, AS800 Series

Power range: 3kV, 250-2500kW

6kV, 250-8000kW

10kV, 250-12500kW

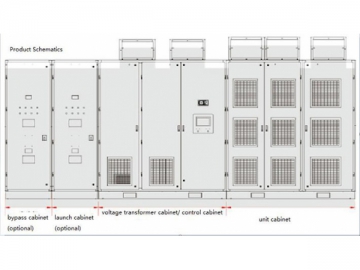

Components

Cabinet Unit: The inverter cabinet unit is composed of several power units in series. The power unit is composed of a three-phase diode bridge rectifier, IGBT bridge inverter, and capacitor, and it features self-protection and monitoring fucntions.

Control cabinet: Features a control system of ARM, DSP, and FPGA. A multi-level PWM control algorithm is adopted to ensure high performance.

Transformer cabinet: A dry phase shifting transformer with H class insulation and CEEG and NST brands, the highest temperature of the system reaches 180℃.

Phase shifting transformer: Reduces harmonic interference and improves power.

Bypass cabinet: When experiencing trouble, the motor will be switched to a manual power grid via the bypass cabinet so production will continue.

Starting cabinet: Prevents the circuit breaker from switching due to large currents when the high voltage converter is in operation. Standard configuration of starting cabinet: 3kV630kW, 6kV1250kW, and 10kV2000kW.

Features

1. Adjustable terminal expansion, even without PLC programming.

2. Vector control and decoupling control of AC motor.

3. High quality drive of motor with multi-level PWM control mode.

4. Small harmonic content less than 5% for a longer service life.

5. Speed tracking startup.

6. Mechanical bypass unit for continuous operation if one unit has trouble.

7. Variable frequency switching.

8. Curve display on touch screen.

9. Busbar voltage self-equalization technique stops deceleration caused by overvoltage.

10. Continuous working when power off. High voltage inverter can output the voltage for 2 seconds. If the high power voltage is recovered, the inverter can resume normal operation.

11. Circulating startup. One frequency converter can start multiple motors with precise phase lock and frequency lock function. The starting current is 2 times that of the rated motor current, and the switching time is within 1s.

12. Synchronous motor control. Supports permanent magnet motor and DC-excited motor.

Other functions

1. Restarts after power failure

2. Power control equipment double loop

3. Input and output voltage, input current is automatically updated when it reaches zero value

4. Droop control, multi-motor synchronous control

5. Inverter will accelerate to and maintain the minimum frequency continuously

6. Supports virtual oscilloscope

7. High voltage switch linkage function

8. Local and remote speed control function