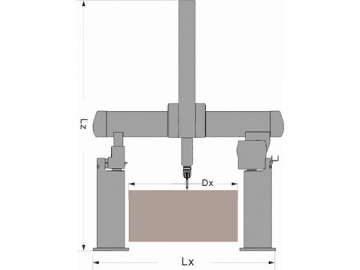

Gantry CMM

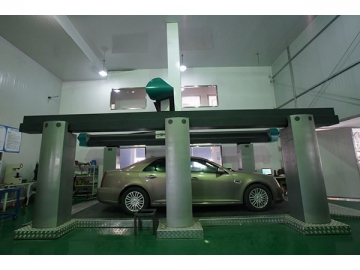

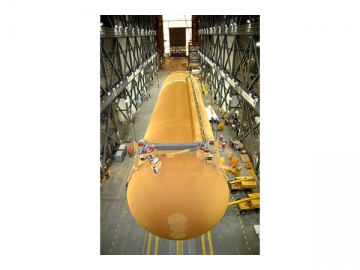

Dimensional inspection of large and ultra-large components on a coordinate measuring machine requires a combination of large volume measuring capability and high precision performance. With rich experience in the design and manufacture of machines for such application, NANO is proud to offer a wide range of gantry coordinate measuring machines.

The Summary series gantry CMM before your eyes is typical one designed for that purpose. It can perfectly meet the requirements of customers in aerospace, moulds and spare parts manufacturing industries for precision measurement and quality verification.

The gantry coordinate measuring machine provides high speed and precision measurement solutions for ultra large parts such as marine engines, aircraft structural parts, turbine vanes, etc. Such measurements need spacious, modular and easy-to-customize structure, so as to achieve unrestricted measuring space. Our Summary series gantry CMM machine is a perfect choice for this goal.

Application fields: Automobile, Aerospace, Heavy Duty Transportation and Mould industries

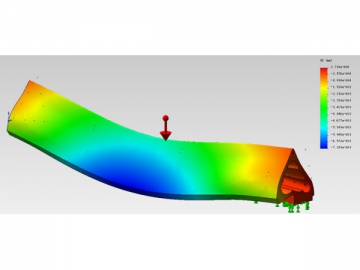

1. This series coordinate measuring machine with gantry construction is F.E.A optimized in guideway structure designs, providing supreme mechanical rigidity, highly improved resistance to deformation, smaller geometric error and higher structural reliability and guideway precision.

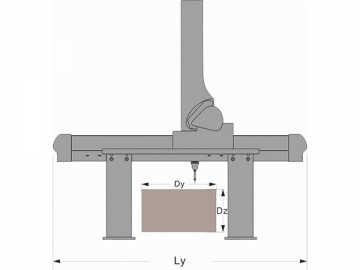

2.The metrology equipment features floor type gantry structure, composed of main and auxiliary columns, Y-axis guideways and moving gantry. Such construction can dramatically reduce the weight of moving parts during motion, thus greatly improving measuring efficiency while ensuring precision. Overall structural configuration offers wider measuring space and provides effective measuring solution for large sized parts.

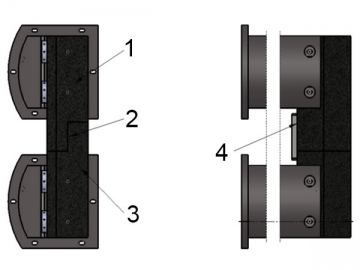

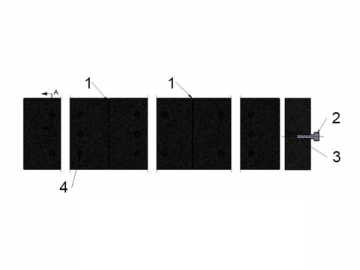

3. Workbench is custom made to meet the requirements of different customers. This offers perfect solution for large scale metrology applications. Workbench of the gantry type coordinate measuring machine boasts butt joint and splicing technology. Via reliable jackscrew adjusting mechanism, errors in all directions reach micron level accuracy.

1. Workbench butt joint 2. Adjusting jackscrew 3. Double tightening nuts 4. Horizontal adjusting mechanism

1. Workbench butt joint 2. Adjusting jackscrew 3. Double tightening nuts 4. Horizontal adjusting mechanism4. Concave and convex supporting blocks for micro-adjustment are mounted on the right angle area of the columns. Not only do they provide guideways with strong enough support rigidity in Z axis direction and ensure reliable straightness, but they also can adjust the levelness and Y-axis parallelism of main and auxiliary guideways. This reliably guarantees measuring accuracy and moving rigidity.

-

1. Supporting block for micro adjustment Workbench butt joint

2. Y-axis guideway

3. Concave and convex supporting blocks -

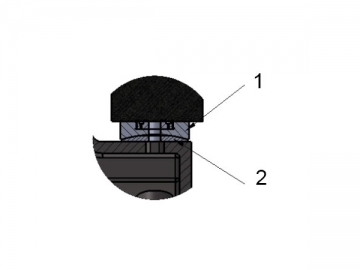

1. Concave supporting block

2. Convex supporting block

5. While providing reliable positioning accuracy, dovetail design increases guideway’s rigidity, thus considerably improving guideway’s resistance to deformation. This provides reliable steady state performance for the gantry coordinate measuring machine.

In addition, guideway with dovetail design is conducive to improvement of motion accuracy along Y-axis and reduction of geometric error. For the measurement that requires more than 8m measuring range, special guideway butt joint technology is used for reliable accuracy.

-

1. Y axis guideway 2

2. Y axis guideway butt joint

3. Y axis guideway

4. Guideway butt plate

6. The gantry of the coordinate measuring machine is designed to runs along Y axis with one end positioned and another free moving end. Such design can effectively eliminate the change of parallelism caused by outside temperature change as well as angular deflection during motion of gantry. As a result, this design effectively improves the gantry CMM’s resistance to temperature change.

1. Gantry free moving end 2.Gantry positioned moving end

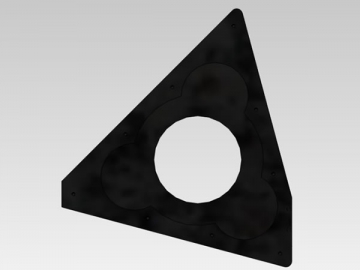

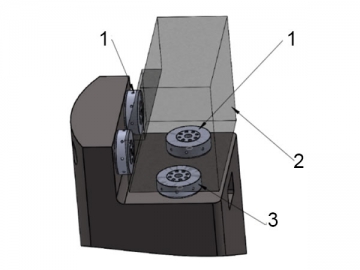

1. Gantry free moving end 2.Gantry positioned moving end7. Moving gantry features a triangular beam design which, on the premise of unchanged quality enhances moving rigidity in Z axis and Y-axis directions, increases sectional area, improves the inertia moment and twisting resistance of beam section, and lowers the center of gravity of moving parts. All these help to improving static and dynamic characteristics of the beam and are of great significance for heightening the measuring precision.

8. By means of professional design software, our Summary series gantry coordinate measuring machine comes with light weight, high rigidity, small geometric error during motion and high machinery stability.

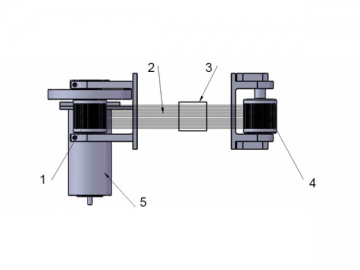

9. Wire rope driving system with unique proprietary technology ensures the measuring system of smaller following error during motion and faster response, thus greatly improving the dynamic performance and minimizing the influence of movement inertia on measuring precision. In addition, wire rope driving system lowers the cost and makes maintenance more convenient.

1. Wire rope wheel at the main end 2. Wire ropes 3. Connecting moving parts 4. Wire rope wheel at the auxiliary end 5. Motor

1. Wire rope wheel at the main end 2. Wire ropes 3. Connecting moving parts 4. Wire rope wheel at the auxiliary end 5. Motor10. This series coordinate measuring machine is creatively designed with a self-protection system to avoid accidents caused by incorrect use of the CMM. This includes Z-axis anti-falling protection, start self-inspection pre-warning system, probe anti-collision system and real-time monitoring system. As abnormal signal is detected, the system will automatically cut it and warns the operator to do related tests. Due to these designs, operational safety is totally ensured.

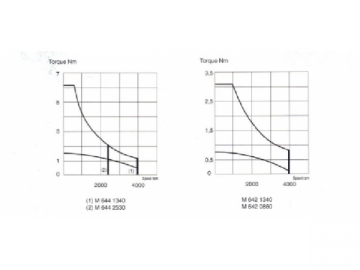

11. Three axes are powered by AMETEK motors which offer high measuring efficiency with high speed performance and ensure reliable accuracy because of superior low speed performance.

12. The gantry type coordinate measuring machine is provided with the RENISHAW measurement system with reflective metal strip gratings. Excellent repeatability with high accuracy can be ensured in that it features similar thermal expansion coefficient with most workpieces.

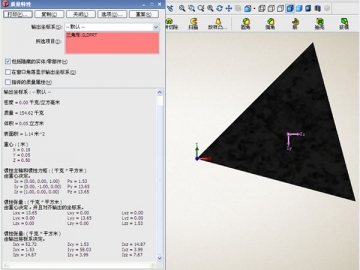

13.21 items of geometric error compensation technologies greatly improve the measuring precision of this gantry measurement equipment.

14. Z axis features adjustable pneumatic balance installation that highly improves the orientation precision and stability of the axis.

15. The coordinate measuring machine for large scale metrology applications comes with an advanced high precision filtration system from Japan. The system assures the compressed air of 5µm filtration accuracy, thus effectively avoiding the damage of starting system caused by bad compressed air quality.

16. To match customer’s actual measuring needs, the gantry CMM is equipped with RENISHAW touch trigger probe or scanning probe.

17. It employs world famous RATIONAL DMIS measuring software that provides perfect measuring and online function.

18. Line laser probe is optional for obtaining point cloud data and completing reverse engineering.

Technical Parameters| Indication error (μm) | 3.5 5L/1000 ~8 5L/1000 |

| Probing error (μm) | 3.5~8.0 |

| Measuring range (mm) | (1500-2500) × (2500-6000) × (1200-2000) |