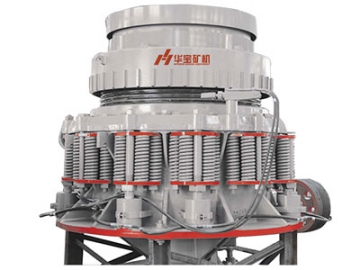

Cone Crusher, PY Series

Applications

Cone crusher of PY series is widely used in metallurgy, building and road construction, chemistry, and silicate industries to break medium to hard rocks and ores, such as iron ore, copper ore, limestone, quartz, granite, basalt, sandstone, coal, etc.

As a typical secondary crusher, the cone crusher can work seamlessly with our feeder, jaw crusher, vibrating screen, and belt conveyor of matching capacities to form a complete minerals processing system. The most suitable crushing chamber configuration should be determined by the end use of crushed ores, as a standard chamber is ideal for medium size reduction, a medium-size chamber for fine size, and a short head bowl for extra fine size reduction.

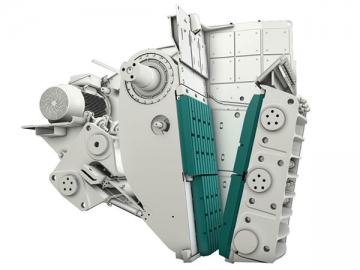

Components

Featured cone crusher consists of the main frame, transmission assembly (including bearings, countershaft, countershaft box, and eccentric shaft), bowl liner, bowl assembly, mantle liner, feed plate, feed distributor, head assembly (crushing cone), adjustment ring, threaded wedge ring assembly, and spring, as well as other attachments.

12 sets of springs for shock absorption, each set containing 5 springs.

12 sets of springs for shock absorption, each set containing 5 springs.- Hydraulic cylinders are used to raise the height of the threaded wedge ring, which in turn adjusts the feed opening.

- Hydraulic wedge ring adjustment for adjusting the opening size.

Inner Workings

Gets the motor started. The motor spins a countershaft. Via a pinion and bevel gear assembly, the rotary motion of the countershaft is transmitted to the eccentric assembly. As the eccentric rotates, the mantle moves either closer to or away from the bowl liner. Rocks are crushed between the gap between the bowl liner and mantle liner.

Features

1. Increased eccentricity for enhanced productivity.

2. High spinning speed and improved power result in finer size reduction. 3. Optimized crushing chamber design.

4. Mantle liner and bowl liner are made of ZGMn13-2 high manganese steel for prolonged wear life.

5. Hydraulic motor is used in place of a hydraulic push rod for precise, continuous adjustment of the opening size at the discharge end. Taking apart the bowl assembly takes only 10 minutes.

6. NSK bearings are used, delivering a low coefficient of friction.

7. Bowl liner, mantle liner, copper bushings, and thrust plate are wear-resistant and dissipate heat fast.

8. One downside to the use of cone crusher is that it requires cleaning after each shift and delivers lower capacity than the S, SGC, and HPC series.

| Model | The diameter of the conical chamber (mm) | Max. infeed size (MM) | Adjustable range of discharge opening (mm) | Capacity (t/h) | Electric motor power (kW) | Swing frequency of main-shaft (mm) | Weight (t) | Overall Dimension (mm) |

| | 900 | 115 | 12-50 | 50-90 | 55 | 333 | 11.2 | 2692×1640×2350 |

| | 900 | 60 | 5-20 | 20-65 | 55 | 333 | 11.2 | 2692×1640×2350 |

| | 900 | 50 | 3-13 | 15-50 | 55 | 333 | 11.3 | 2692×1640×2350 |

| | 1200 | 145 | 20-50 | 110-168 | 110 | 300 | 24.7 | 2790×1878×2844 |

| | 1200 | 100 | 8-25 | 42-135 | 110 | 300 | 25 | 2790×1878×2844 |

| | 1200 | 50 | 3-15 | 18-105 | 110 | 300 | 25.3 | 2790×1878×2844 |

| | 1750 | 215 | 25-60 | 280-480 | 160 | 245 | 50 | 3910×2894×3809 |

| | 1750 | 185 | 10-30 | 115-320 | 160 | 245 | 50 | 3910×2894×3809 |

| | 1750 | 85 | 5-15 | 75-230 | 160 | 245 | 50 | 3910×2894×3809 |

| | 2200 | 300 | 30-60 | 590-1000 | 280 | 220 | 80 | 6440×2900×5057 |

| | 2200 | 100 | 5-15 | 120-340 | 280 | 220 | 81.4 |

| Model | Size(mm) | ||||

| A | B | C | D | E | |

| | 458 | 2358 | 1135 | 1250 | 1690 |

| | 650 | 2550 | 1670 | 1645 | 2815 |

| | 845 | 3505 | 2120 | 2255 | 3585 |

| | 950 | 4852 | 3025 | 2700 | 4080 |