Firing System

Temperature control is vital in a fast firing process, allowing an extremely narrow margin of error. Failure to control temperature may lead to unsightly cracks and wrinkles on the surface of material being dried.

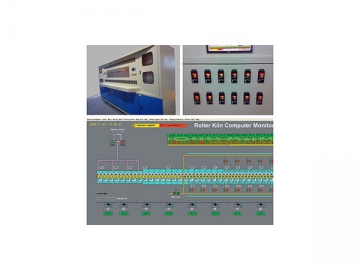

For that reason, the firing system of our roller kiln is fitted with several temperature controls. Each temperature control assembly has two control units installed above and below the conveyor rollers. Each control unit has an individual thermostat, motor operated valve, thermocouple and several burners.

The majority of burners we use in the firing system have low flow capacities. Multiple burners of the same heating power are located horizontally on the walls of the kiln above and below the rollers in a staggered pattern. This staggered arrangement ensures high uniformity of kiln temperature and easy temperature adjustment. The specially designed burner mixes and preheats fuels and combustion air, and produces a horizontal jet of flame that heats the kiln chamber evenly. Thus, a small temperature gradient can be achieved across the width of the kiln chamber with a ±2°C temperature control accuracy.

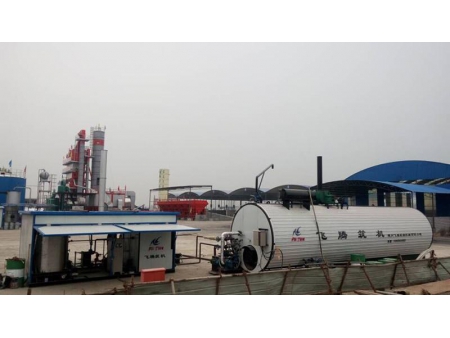

Due to safety concerns, the natural gas storage system comes equipped with a pressure gauge, filter, pneumatic safety valve, blow off valve, and explosion proof devices, among other safety features.