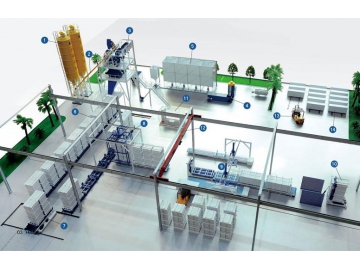

EPS Production Line

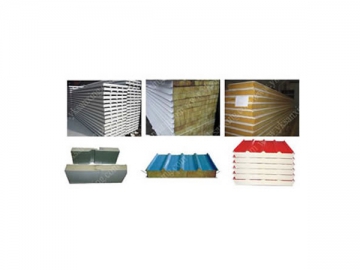

The EPS, expandable polystyrene, is hard closed-cell foam. It is usually white color and made of pre-expanded polystyrene beads. These beads are expanded and join together in the process of steam heating and pressure treatment with our EPS producing line. The small beads enlarge as much as 40 times and they are converted in EPS blocks that will be used in countless applications around the world in all kind of industries.

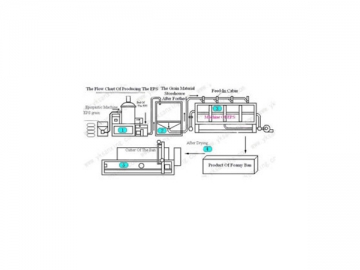

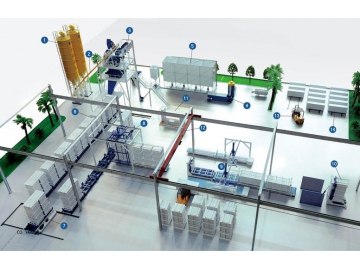

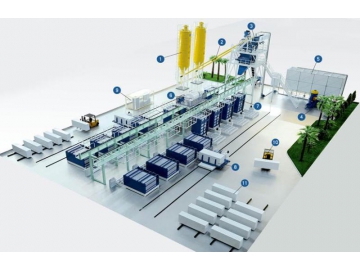

The EPS producing line counts with high automation degree with PLC and touchscreen display for easiest control. It has some tasks like mould open, mould close, material feed, heating, preserve heat, air cooling, vacuum cooling, de-moulding and ejecting that can be done by semi-automatic or full automatic functions. It has air cooling type with fast forming time producing low moisture.

One of the features of the EPS production line that makes it work faster than others from its type, is the equally heat distribution with exhaust ducts that prevents wasting of heat or steam. The machine is welded from high quality profile steel through heat treatment ensuring high strength without deformation. It's possible to bear the expansion force of the high density and thick block without any problem.

The main machine's cavity is made of high quality aluminum alloy plate and is coated with Teflon. Our modern EPS producing line is easy to de-mould. It has a big feed gun to insert material faster than previous models. It usually comes with pre-expander, block molding machine, silo, automatic oil boiler, steam tank compressor air, air tank, dry room or dry bed and recycling machine.

Other search items: guardrail/safety barrier manufacturing equipment